Underground mining stone-prying carry-scraper and mining method thereof

A scraper and shoveling technology, which is applied to underground mining prying scraper and its mining field, can solve the problems of high safety risk of manual prying, reduction of prying working surface, and difficulty in equipment transfer, so as to avoid Deviating from the working area, improving the accuracy of prying hair, and facilitating real-time remote understanding of the status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

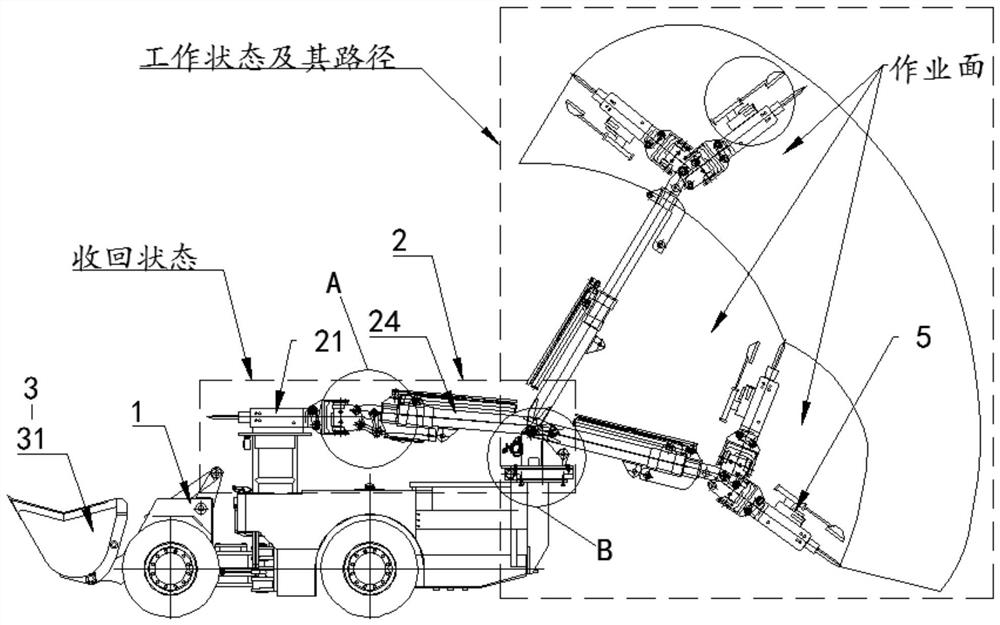

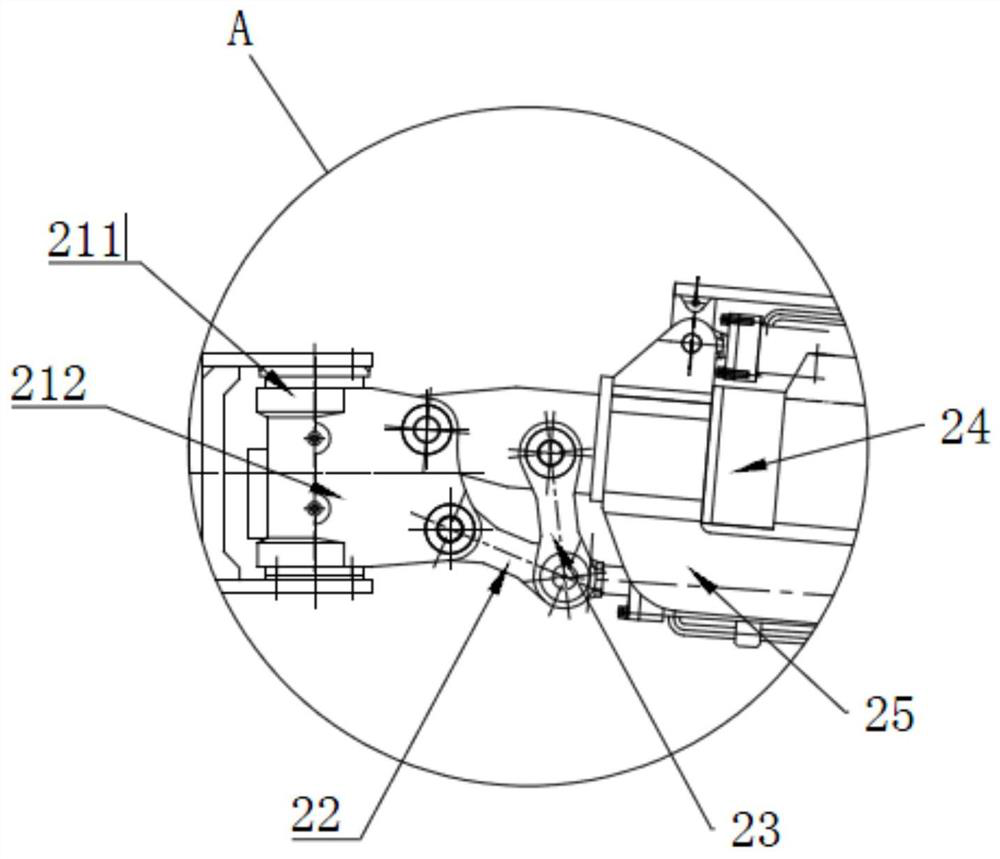

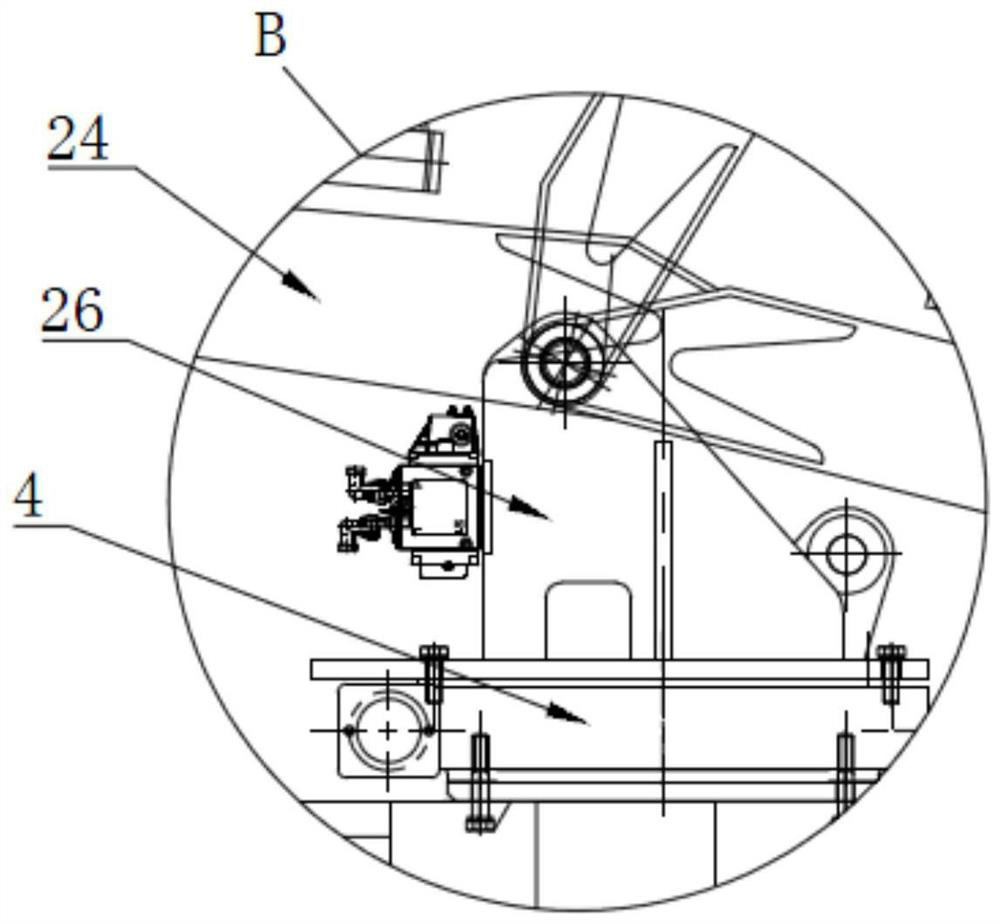

[0040] A prying scraper for underground mining, such as figure 1 and Figure 4 Shown, comprise car body 1 and be arranged on car body 1 pry hair mechanism 2 and scraper mechanism 3, wherein, scraper mechanism 3 is arranged on the front side of car body 1, pry hair mechanism 2 is arranged on car body 1 The rear side is driven by the hydraulic rotary mechanism 4 to rotate; when the prying scraper is walking, the hydraulic rotary mechanism 4 drives the prying mechanism 2 to rotate to the front of the car body 1; when working, the hydraulic rotary mechanism 4 drives the prying Hair mechanism 2 rotates to car body 1 rear side and pries hair.

[0041] In order to improve the utilization rate of the equipment, the present invention is provided with a prying mechanism 2 and a shoveling mechanism 3 on the car body 1, and the mine is pried by the prying mechanism 2, and then the ore is transported out by the shoveling mechanism 3 In order to improve the operating area of the prying ...

Embodiment 2

[0050] Embodiment 2, the difference with embodiment 1 is

[0051] Such as figure 1 , 5 As shown, it also includes a tracking survey mechanism 5 for remote observation of prying effects; the tracking survey mechanism 5 includes a camera 51, a light fill device 52, a display screen, a remote gateway, a controller and a local dust suction structure 53; The camera 51 is installed on the prying mechanism 2 through a lifting structure and is electrically connected to the controller and the display screen through a remote gateway; the light supplement 52 is installed directly below the camera 51 and is electrically connected to the controller; the dust suction structure 53 includes being arranged directly above the camera 51 through the telescopic component 8.

[0052] The dust collection structure includes a vacuum cleaner, a collection bucket, and a flexible pipe with a telescopic function; the vacuum cleaner is installed on the output end of the telescopic part and moves with th...

Embodiment 3

[0061] In addition, the present invention also discloses a prying and shoveling method for an underground mining prying and shoveling machine, which is characterized in that it includes the following steps:

[0062] S1 Pre-survey: Pre-survey the position of the prying hair through the survey mechanism, and have realized the proofreading and positioning of the output position of the prying hair mechanism;

[0063] S2 prying: when working, the hydraulic rotary mechanism drives the prying mechanism to rotate to the rear side of the car body for prying;

[0064] S3 Survey: While the prying work is in progress, the survey mechanism starts, the vacuum mechanism moves to the prying area through the telescopic mechanism to absorb the dust generated by the prying, the light fill device starts to illuminate the prying area, and the camera clearly captures the prying area The condition of the rock wall; the prying mechanism can be adjusted freely according to the actual rock wall conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com