[0003] 1. Most of the existing electric windows will generate operating

noise during the electric opening and closing process, which greatly reduces the user experience of users;

[0004] 2. In the existing electric windows driven by the driving principle of the wire rope and the reel, the wire rope will be severely worn, and the severity of the wear will increase with the increase of the load of the wire rope. When the movable window is affected by the wind pressure and the speed is uneven and vibrates, the probability of wire rope winding will increase, thereby reducing the reliability of the entire

system;

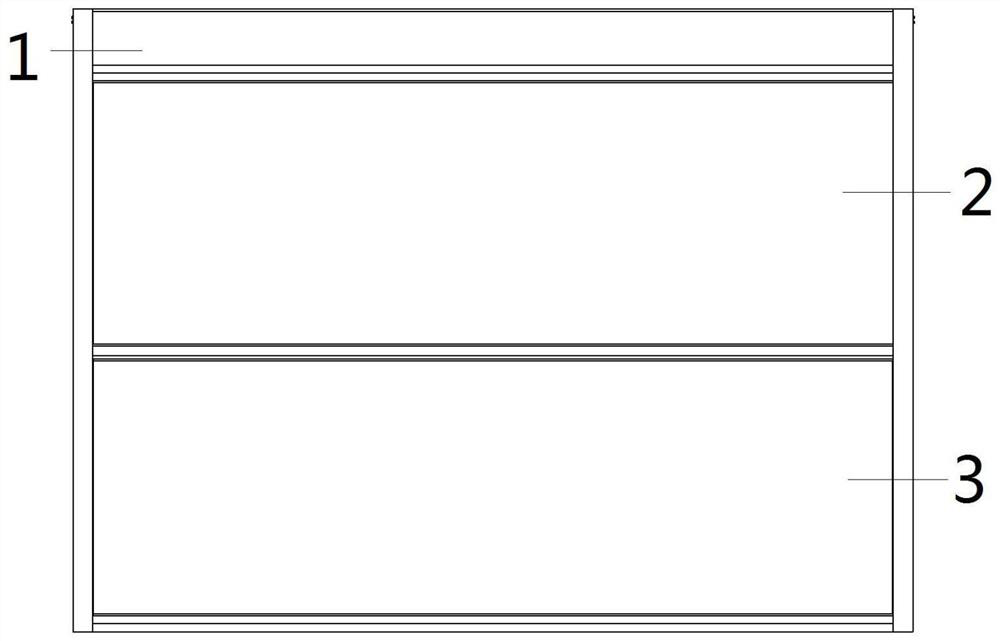

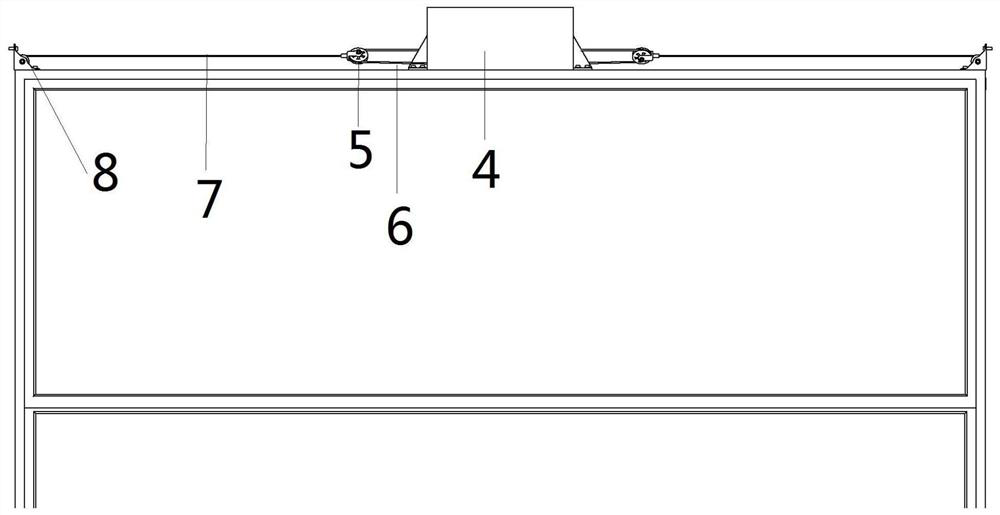

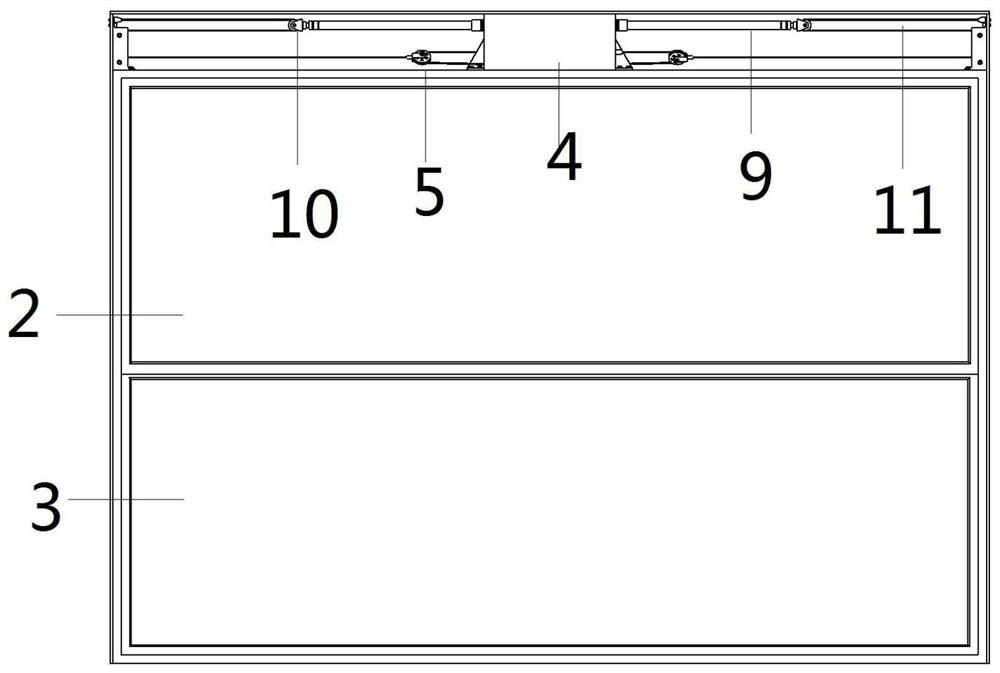

[0005] 3. For the existing electric lift windows, the movable window is on the top and the fixed window is on the bottom. When the window is closed, the movable window is not effectively kept in a sealed state, and the sound insulation and heat preservation performance cannot meet the national energy-saving standards. The sound insulation and heat preservation performance of the electric window If it is not strong, the cold wind will enter the room through the gap of the electric window in winter, and the road noise cannot be effectively blocked;

[0006] 4. Existing large electric windows, because the movable windows are large and heavy, the specifications of the motor are very large, which makes the motor unable to be hidden inside the window frame profile or the window frame profile is too thick, and the

power consumption and operating noise are also large;

[0007] 5. Many existing electric windows have driving parts exposed outside the window frame, which is very unsightly

The frame profiles on both sides of some electric windows are very thick, and some electric windows are not on the same plane as the fixed windows when they are closed, or some electric windows are not on the same plane as the glass

curtain wall when they are closed, so the outer windows are not beautiful and not sealed

When some electric windows are opened, the movable windows protrude to the outside or to the interior. The above-mentioned electric windows all affect the aesthetics of the indoor and outdoor windows of the place, and also affect the aesthetics of the facades of urban buildings;

[0008] 6. Most of the existing electric windows need regular maintenance, because now some electric windows are installed in high positions and places that are inconvenient for people to reach. Regular maintenance is a high-altitude operation and the cost is very high, and it will also affect the operation of the place of use.

[0010] The technical solution of the application number CN202010635274.3 has the following disadvantages: 1. The fixed window is at the upper part of the opening of the outer window, and the movable window is at the lower part of the opening of the outer window. Window openings fall or objects are accidentally dropped from high-rise buildings; 2. According to national

construction engineering standards, the distance from the bottom of the outer

window opening to the indoor ground should be greater than 1.1 meters, that is to say, the entire product of the technical solution of CN202010635274.3 will be set at a distance from the indoor ground. The position is greater than 1.1 meters, and the fixed window of this product is on the top, so the area of the movable window that can be opened is very small, which is not conducive to indoor ventilation of the place and

smoke exhaust in case of fire; 3.

Fire smoke starts to accumulate from the upper part of the place ,

Fire smoke is high-temperature, toxic and

lighter than air.

Fire smoke naturally has the property of spreading upward at a high speed to the window. The closer the movable window is to the upper part, the higher the

smoke exhaust efficiency of

fire smoke is. However, the technical solution for fixed windows The upper part is not conducive to the

smoke exhaust of the fire; 4. The

root cause of this technical solution is that the fixed window is on the upper part and the movable window is on the lower part is that when the movable window is very large and heavy in this technical solution, the movable window needs to rely on the window frame below to support the movement The self-weight of the window keeps the outer window closed for a long time; 5. The power-assisted mechanism and the driving mechanism of this technical solution are very bloated, causing the frame above the movable window to be too high, which affects the aesthetics. Fault, the entire intelligent exterior window cannot be opened and closed; 6. When the technical solution is closed, the movable window and the fixed window are not on the same

vertical plane, which affects the beauty of the building's facade, and also affects the beauty of the indoor window; 7. Because the movable window and the fixed window are not on the same

vertical plane when the technical solution is closed, there is no action of pressing and sealing the movable window inward when the movable window is closed, so the sealing, watertightness and airtightness of the technical solution , sound insulation, heat preservation and other key performance indicators of external windows are not excellent; insufficient sealing performance will also cause dust and salt spray from the sea to invade the drive mechanism and booster mechanism through the opening slot, resulting in the need for regular maintenance of parts. Now some electric windows are installed In places where high positions and other people are inconvenient to reach, the cost of maintaining electric windows is very high when working at heights; 8. The

line of sight of the

human eye is 1.6 meters above the ground and spreads along the horizontal direction. This height of the technical solution is the position of the fixed window. Person viewing outdoor landscape is separated by glass and

dirt on glass

[0011] The technical solution of application number 201310036583.9 has the following disadvantages: 1. The traditional spiral rope groove drum winding method is adopted. The principle of orderly winding of the steel wire rope in this way is to rely on the sliding friction between the steel wire rope and the spiral concave groove to make the steel wire rope slide into the predetermined track (Concave rope groove refers to the concave groove on the reel that is in contact with the wire rope winding, the same below), although a reel cover (1309) is installed outside the reel, if the steel wire rope will jump, the reel cover will Forcibly block the steel wire rope, so that the steel wire rope is not easy to hop. At this time, the steel wire rope and the drum cover are in sliding friction. After the product is used for a long time, the steel wire rope will be severely worn, and the severity of the wear will increase with the load of the steel wire rope. ; This kind of reel relies on the pressure of the concave rope groove on the reel to the steel wire rope during the rope winding process to make the steel wire rope "slide" into the predetermined groove. There is sliding friction between them, and the steel wire rope is guided through the concave rope groove ( Orderly winding) the pressure of the concave rope groove on the wire rope (the pressure of the non-perpendicular to the axis of the reel) is mainly concentrated at the tangent point between the wire rope and the reel (the tangent point between the wire rope pulled into a straight line and the circular reel) point position), during the rope winding process, the steel wire rope is subject to huge pressure in the tangent point area and at the same time slips and generates sliding friction (the steel wire rope also undergoes a small rotation while sliding friction occurs, and the steel wire rope needs to

resist its own torsion), When the

friction coefficient between the wire rope and the reel is constant, the

frictional resistance of the wire rope is the largest at the point of tangency, and when the tension on the wire rope is greater, the pressure acting on the reel is also greater, and the resulting

frictional resistance is also greater. The bigger it is, the greater the degree of wear on the wire rope

Although the traditional

helical rope groove or broken line rope groove reel has a simple structure, there are many limitations in some systems that require a high safety factor or are used for many years without replacing parts. When the speed increases, the wear-resistant material on the surface of the wire rope is worn away, and the

friction coefficient between the wire rope and the groove wall of the reel will increase. When the

machine is running, when the speed of the rope is accelerated or the movable window is affected by the wind pressure when the rope is rolled, the speed is not uniform. When vibrating, the probability of wire rope winding will increase, thereby reducing the working reliability of the whole

system; When reeling or unwinding, because the wire rope (15) will move back and forth in the axial direction of the reel, and the smaller the distance between the two axes, the greater the deviation angle of the wire rope (15) on the fixed

pulley (14). This will speed up the wear of the wire rope, and at the same time, the larger the offset angle, the lower the transmission efficiency, which will reduce the reliability and service life of the mechanical work; 3. Due to the working principle and design

layout of the product, responsible for providing movable windows The direct power of the up and down movement comes from the reel (1308) and the fixed

pulley (14) at the top of both sides of the window, so that the frame on both sides of the whole window cannot be very narrow, which will make the profiles on both sides of the whole window bloated, and the outer window The frame is very large and the aesthetics are very poor; 4. This technical solution does not have a booster device. When the weight of the movable window is heavy, the requirements for the motor are very high, and the strength requirements for the steel wire rope and related parts are higher.

Login to View More

Login to View More  Login to View More

Login to View More