Method, system and equipment for predicting service life of tower drum of wind turbine generator and storage medium

A technology for life prediction and wind turbines, which is applied to mechanical equipment, wind power generation, wind engines, etc., and can solve problems such as inability to accurately and effectively predict and evaluate tower loads and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

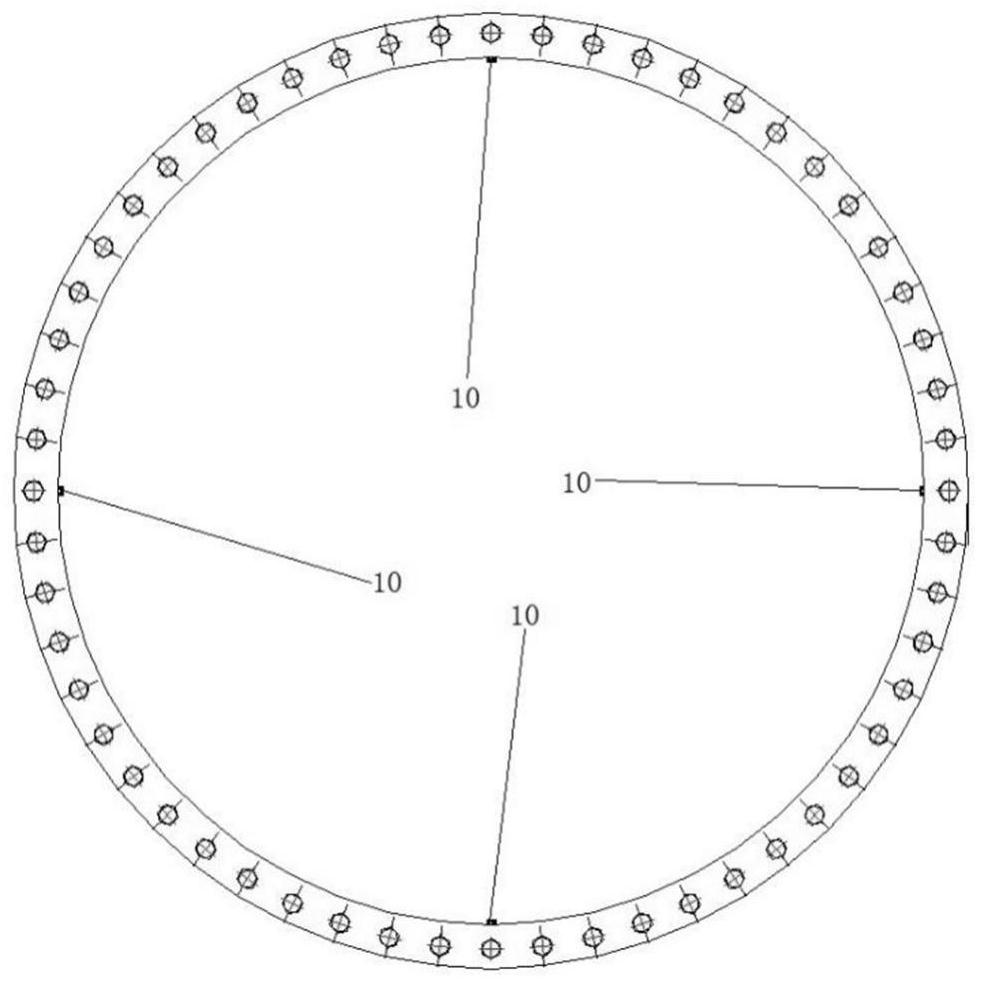

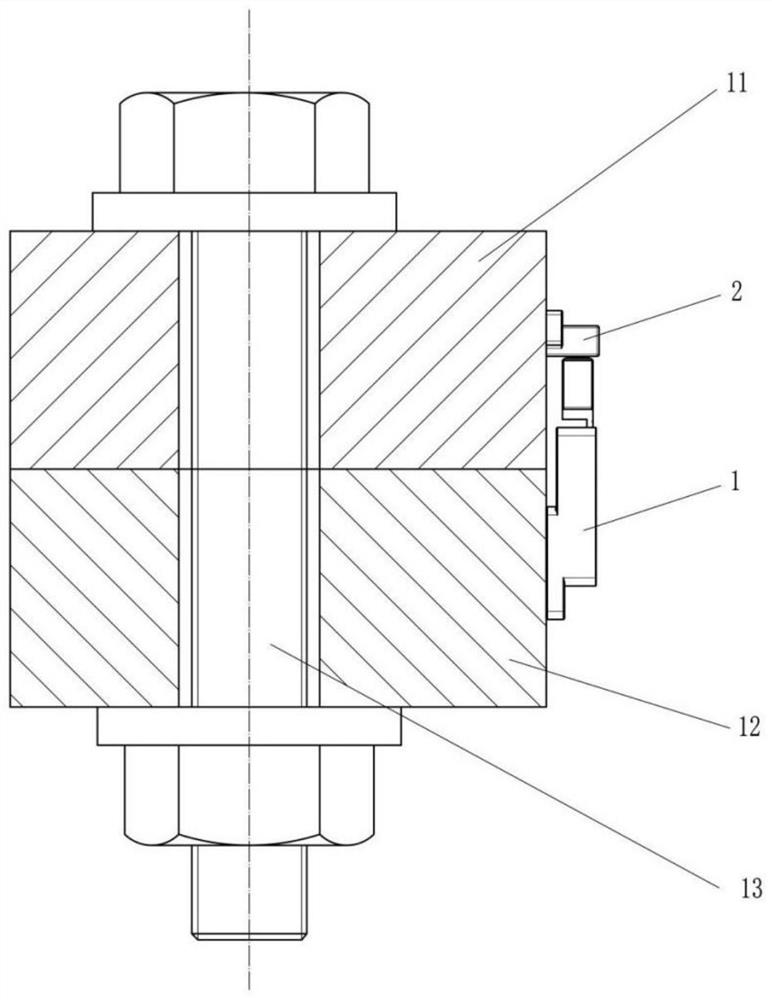

[0098] A wind turbine tower life prediction method, such as figure 1 with Figure 4 As shown, several connectors are installed on the tower body of the wind turbine. Figure 5 As shown, the connecting piece includes an upper flange 11 and a lower flange 12, bolts 13 are arranged on the upper flange 11 and lower flange 12, an upper gasket 14 is arranged between the upper flange 11 and the bolt 13, and the lower flange A lower gasket 15 is provided between 12 and the bolt 13 .

[0099] implementation of methods such as Figure 7 shown, including the following steps:

[0100] S1: measure the displacement data by the displacement sensor 10, and transmit the displacement data to the host computer for processing;

[0101] S2: Calculate the working load on each layer of flange based on the data processed by the host computer;

[0102] S3: Calculate the stress data of each layer of flanges and related welds, and the ring section of the tower shell through the calculation of the w...

Embodiment 2

[0105] Except for the following content, all the other contents are the same as in Example 1.

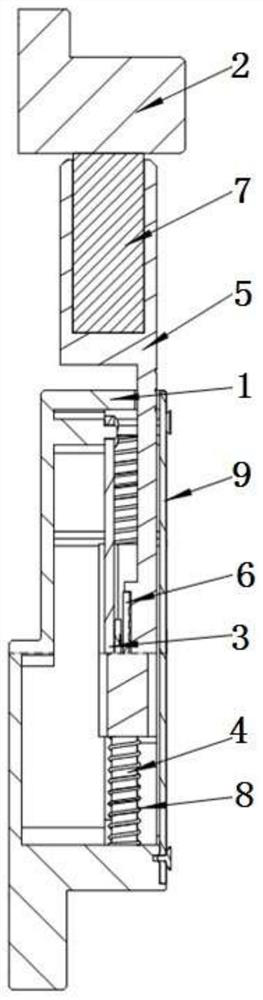

[0106] The displacement sensor 10 is a split type displacement sensor, and the displacement sensor 10 includes a limit block 2 and a displacement sensor body, and the limit block 2 and the displacement sensor body are respectively fixed on two interconnected connectors. The displacement sensor 10 is evenly installed on the inner or outer circumference of the flange connection, and the spacer 2 and the sensor body separated from each other in the displacement sensor 10 are respectively fixed on the two interconnected flanges.

Embodiment 3

[0108] A wind turbine tower life prediction method, such as figure 2 with image 3 shown, including the following steps:

[0109] S1. Evenly install the high-precision displacement sensor 10 on the inner or outer circumference of the flange connection, and fix the spacer 2 and the sensor body separated from each other in the high-precision displacement sensor 10 to the two interconnected flanges respectively. Lan Shang;

[0110] S2. When the tower is subjected to an external load, the axial relative displacement of the upper flange 11 and the lower flange 12 changes, and occurs between the limit block 2 installed on a pair of flanges and the sensor body (housing 1). Relative displacement, the magnet 6 on the high-precision displacement sensor 10 slides on the surface of the electromagnetic induction chip, the magnetic field around the high-precision electromagnetic induction chip changes linearly, the high-precision electromagnetic induction chip captures the change of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com