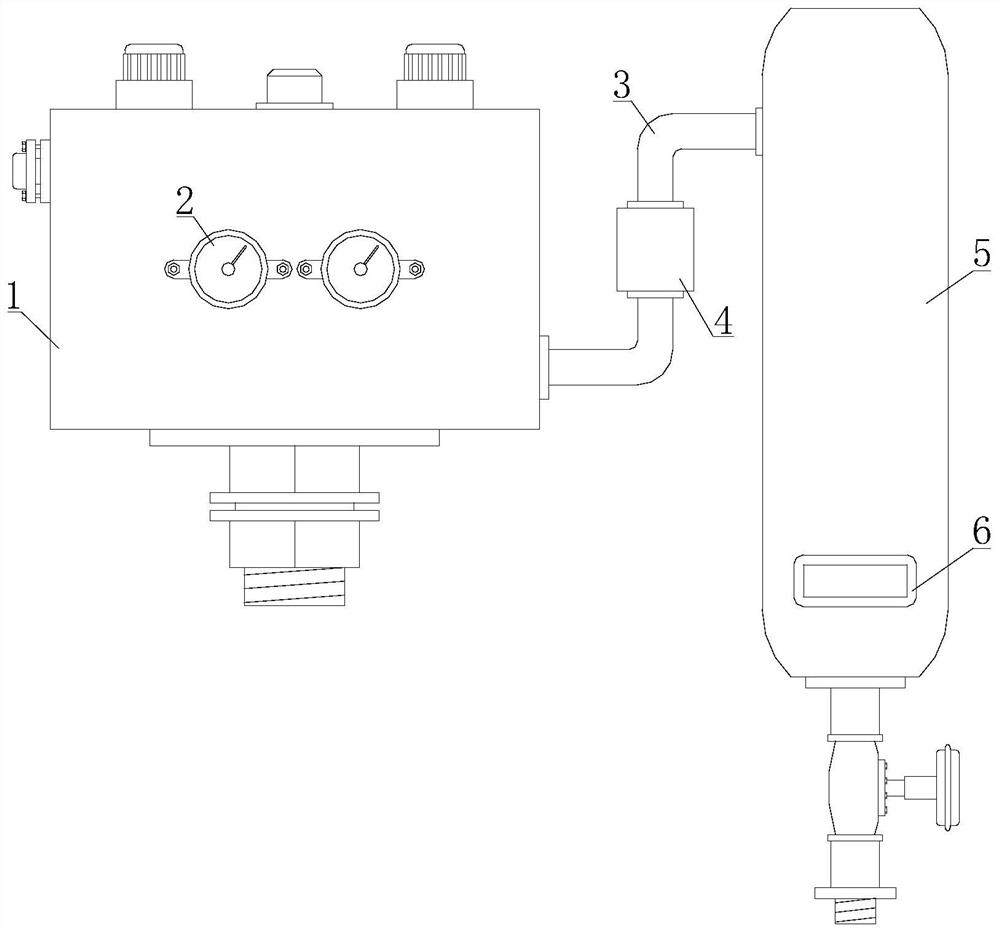

Iron-molybdenum method formaldehyde flue gas waste heat recycling device and implementation method thereof

A technology of flue gas waste heat and formaldehyde, applied in separation methods, chemical instruments and methods, heat exchangers, etc., can solve problems such as non-recyclable use, stimulating effect, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

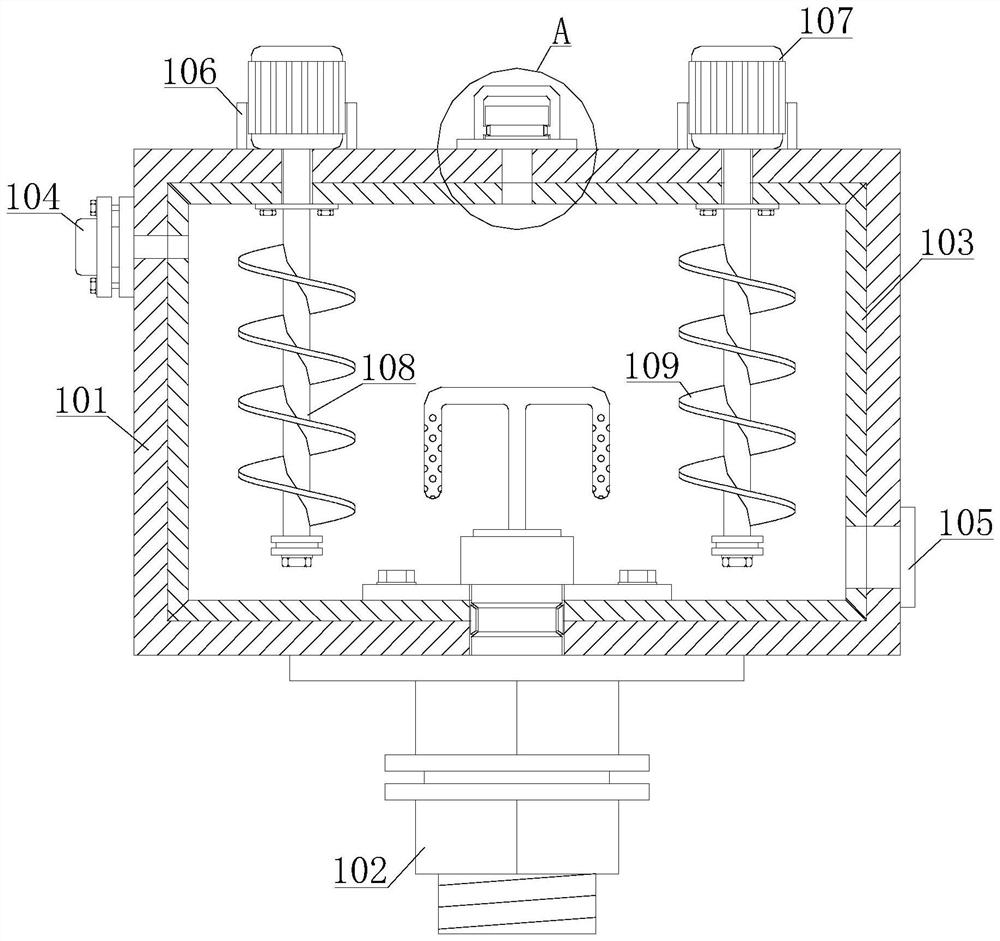

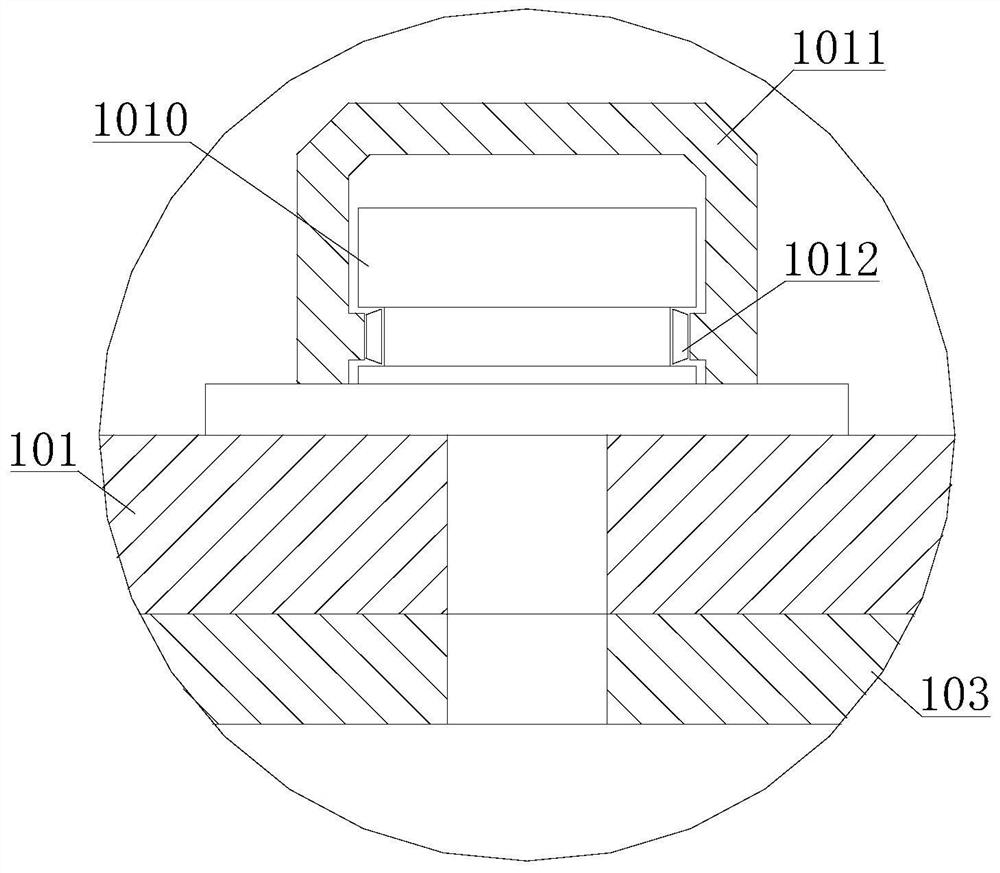

[0031] In order to better demonstrate the implementation process of the iron-molybdenum method formaldehyde flue gas waste heat recycling device, this embodiment now proposes an implementation method of the iron-molybdenum method formaldehyde flue gas waste heat recycling device, including the following steps:

[0032] Step 1: Install the threaded interface 10210 at the bottom of the heat exchange kettle 1 on the formaldehyde preparation equipment, turn on the exhaust motor 10213, use the exhaust fan blade 10214 to absorb the formaldehyde fume, and transport it to the gas storage tank 1026 through the clamping tube 1022 middle cache;

[0033] Step 2: The gas in the gas storage tank 1026 continues to enter the bubbling tube 1027 upwards, and bubbles from the bubbling hole 1028 to the cooling water in the kettle shell 101, and is evenly stirred by the stirring shaft 108 and the stirring blade 109 to make the formaldehyde The temperature of the flue gas is transferred to the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com