Temperature-controlled, pressure-controlled and energy-saving eclectic seeds-frying machine

A technology of frying seed machine and electric motor, applied in application, food processing, food science and other directions, can solve the problems of temperature difficulties, waste, environmental temperature rise, etc., to reduce maintenance costs, prolong equipment service life, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

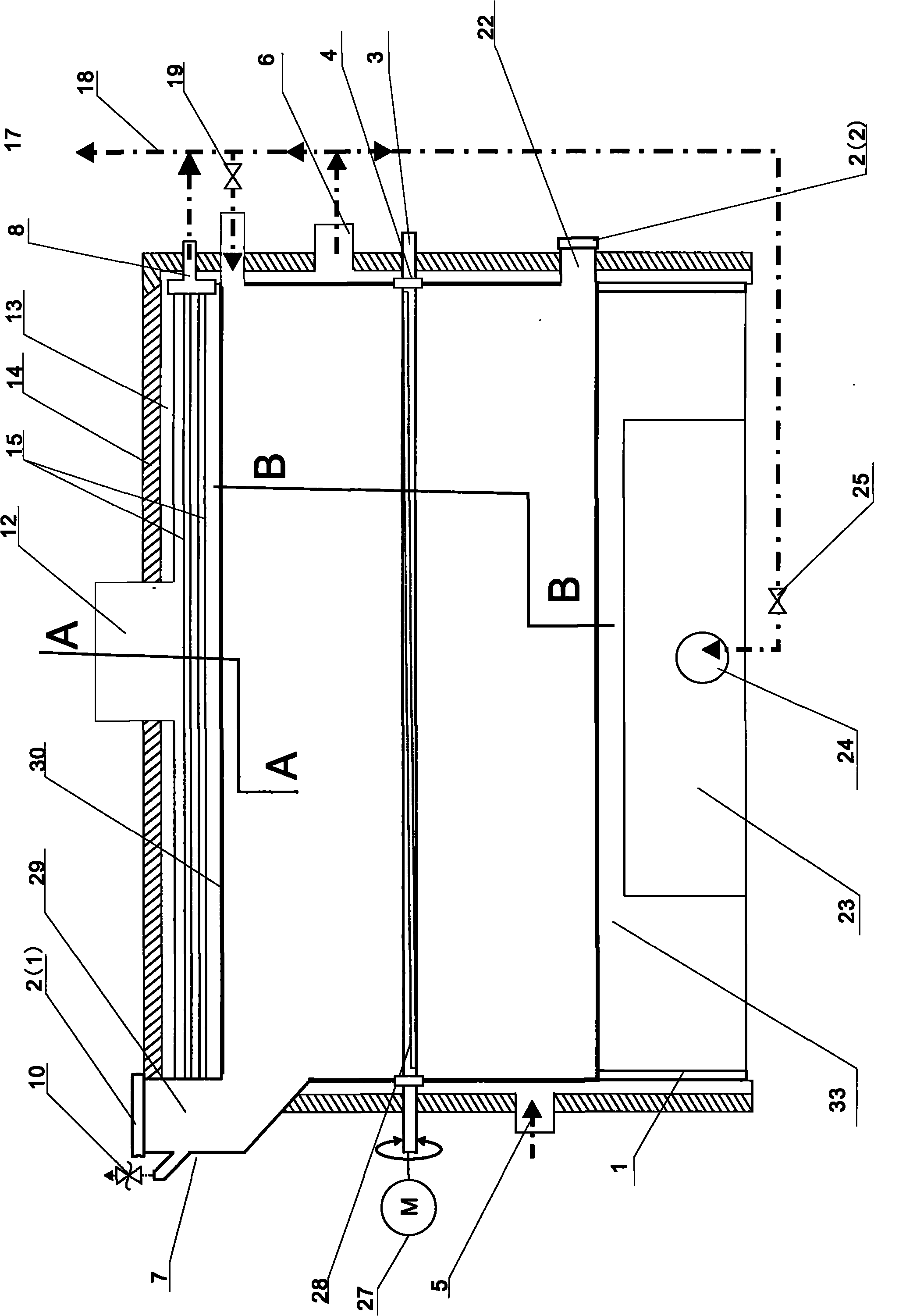

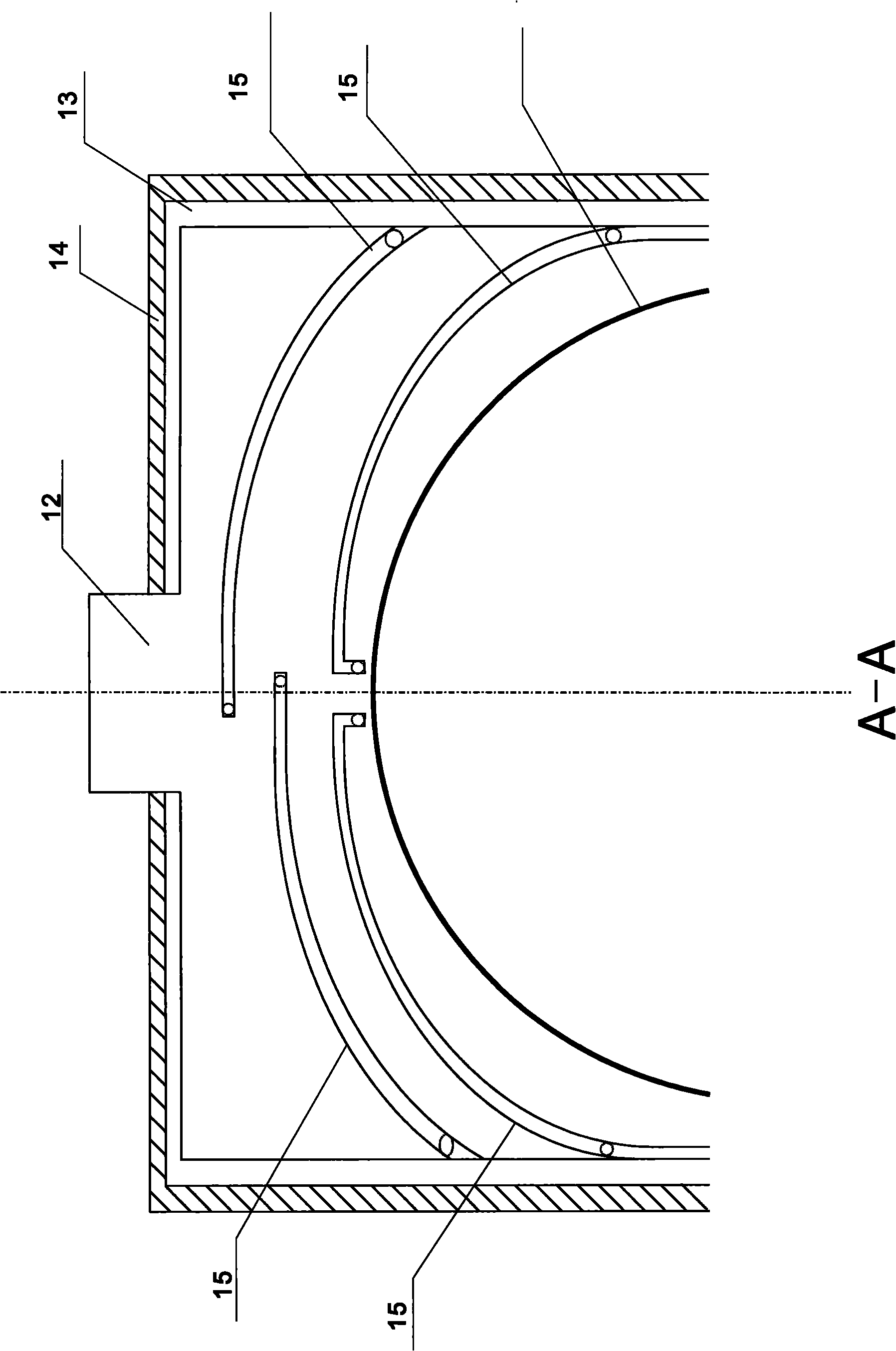

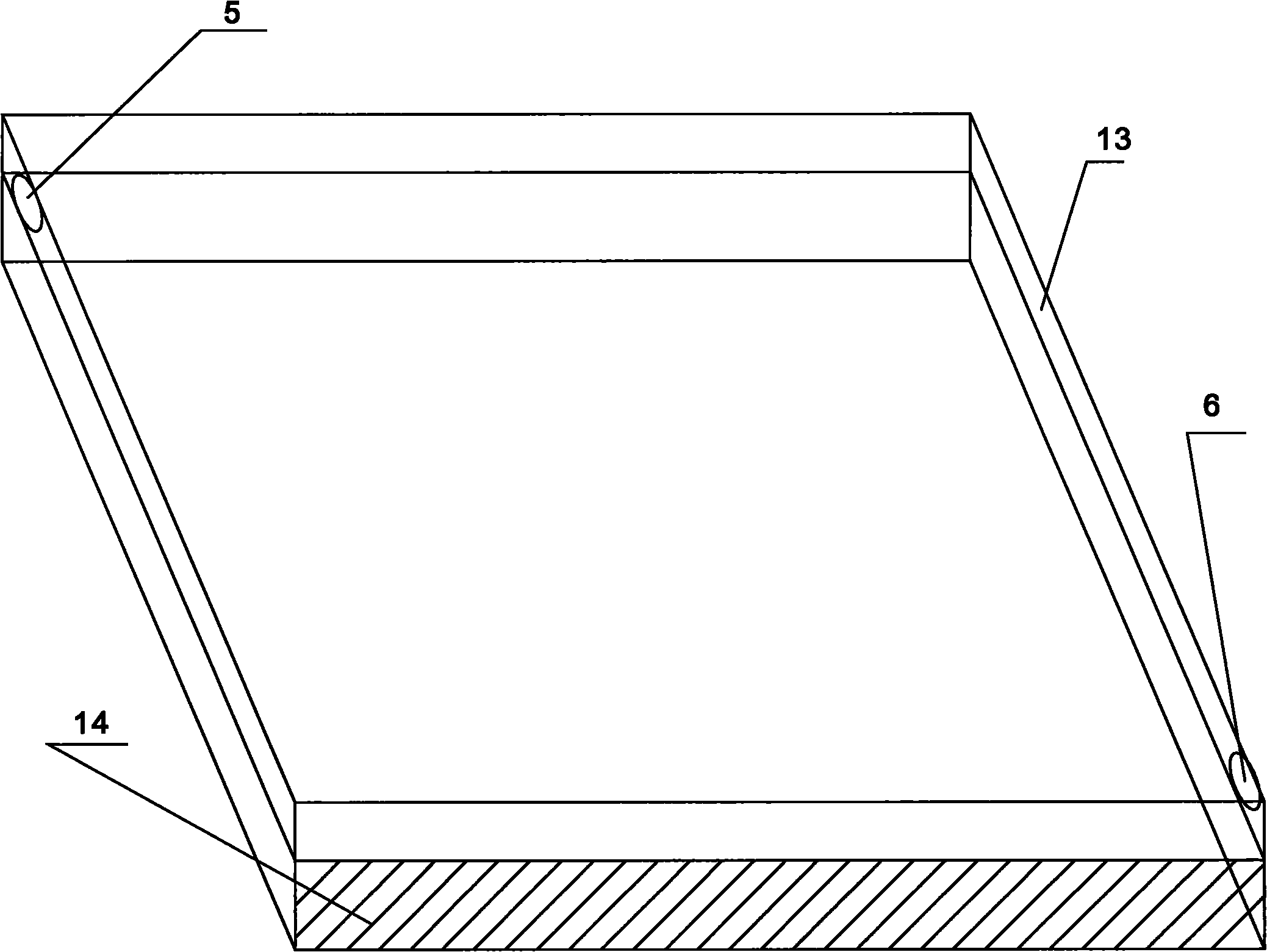

[0030] best practices (such as Figure 5 shown)

[0031] In the basic structure of the seed frying machine involved in the present invention (as figure 1 ) on the basis of adding 26 blowers, 9 temperature measuring contacts, 16 thermometers, 17 pressure gauges, 10 safety valves, 11 pressure relief valves, 20 thermostats and other components at the corresponding positions and the signals and power supplies of the corresponding components The line is connected to the 21 control box for unified and centralized control, so that we can get a brand new energy-saving electric seed frying machine with automatic temperature and pressure control.

[0032] In the specific production application of this seed frying machine, especially when the seeds need to be steamed and fried (such as Invention Application No. 200810182249.3), the following operation will especially give full play to its unique advantages:

[0033] Water is selected as the heat transfer fluid medium introduced into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com