Ultrasonic coupling agent for flaw detection of railway steel rail joints and train hubs and preparation method of ultrasonic coupling agent

A train wheel and ultrasonic technology, which is applied in the direction of material analysis, instruments, and measuring devices using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as long-term storage, hidden safety hazards, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

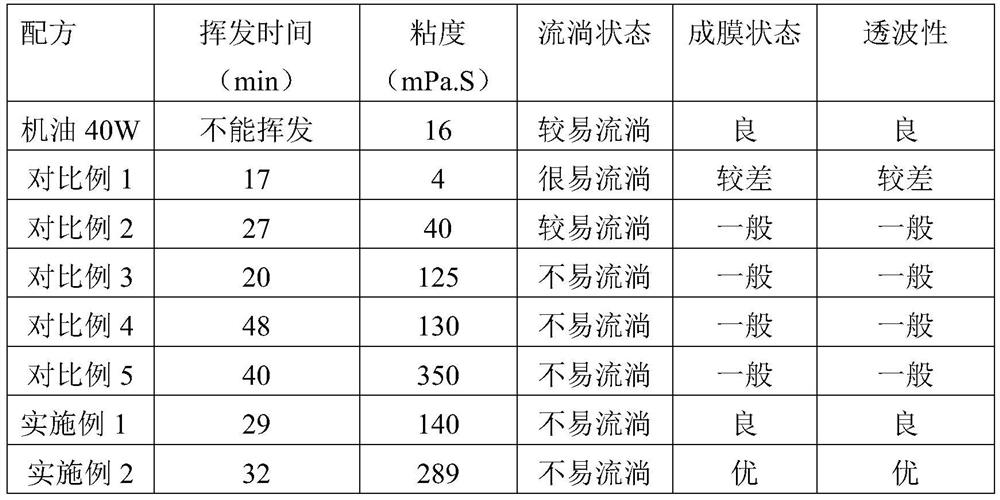

Examples

Embodiment 1

[0022] An ultrasonic coupling agent for flaw detection of railway rail joints and train hubs, comprising the following raw materials in mass percentage: 30% ethanol, 5% ethylene glycol, 64.2% water, and 0.8% hydroxyethyl cellulose.

[0023] The preparation method of the above-mentioned ultrasonic coupling agent for railway rail joints and train hub flaw detection comprises the steps of: after mixing ethanol, ethylene glycol and water evenly, adding hydroxyethyl cellulose in 4 batches, and stirring at a stirring rate of 2 rpm After the hydroxyethyl cellulose is completely dissolved, the ultrasonic coupling agent is obtained.

[0024] The low temperature resistance of the couplant obtained in this example can reach -40°C.

Embodiment 2

[0026] An ultrasonic coupling agent for flaw detection of railway rail joints and train hubs, comprising the following raw materials in mass percentage: 30% ethanol, 5% ethylene glycol, 64% water, and 1.0% hydroxyethyl cellulose.

[0027] The preparation method of the above-mentioned ultrasonic coupling agent for railway rail joints and train hub flaw detection comprises the steps of: after mixing ethanol, ethylene glycol and water evenly, adding hydroxyethyl cellulose in 4 batches, and stirring at a stirring rate of 2 rpm After the hydroxyethyl cellulose is completely dissolved, the ultrasonic coupling agent is obtained.

[0028] The low temperature resistance of the couplant obtained in this example can reach -40°C.

Embodiment 3

[0030] An ultrasonic coupling agent for flaw detection of railway rail joints and train hubs, comprising the following raw materials in mass percentage: 30% ethanol, 5% ethylene glycol, 64.1% water, and 0.9% hydroxyethyl cellulose.

[0031] The preparation method of the above-mentioned ultrasonic coupling agent for railway rail joints and train hub flaw detection comprises the steps of: after mixing ethanol, ethylene glycol and water evenly, adding hydroxyethyl cellulose in 4 batches, and stirring at a stirring rate of 2 rpm After the hydroxyethyl cellulose is completely dissolved, the ultrasonic coupling agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com