A non-intrusive real-time fault monitoring method for train bogies

A non-intrusive, real-time fault technology, applied in railway vehicle testing, measuring devices, character and pattern recognition, etc., can solve problems such as large redundancy, high cost, affecting bogie structure optimization and lightweight design, and achieve improved Accuracy and stability, cost savings, effects of avoiding sensor redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

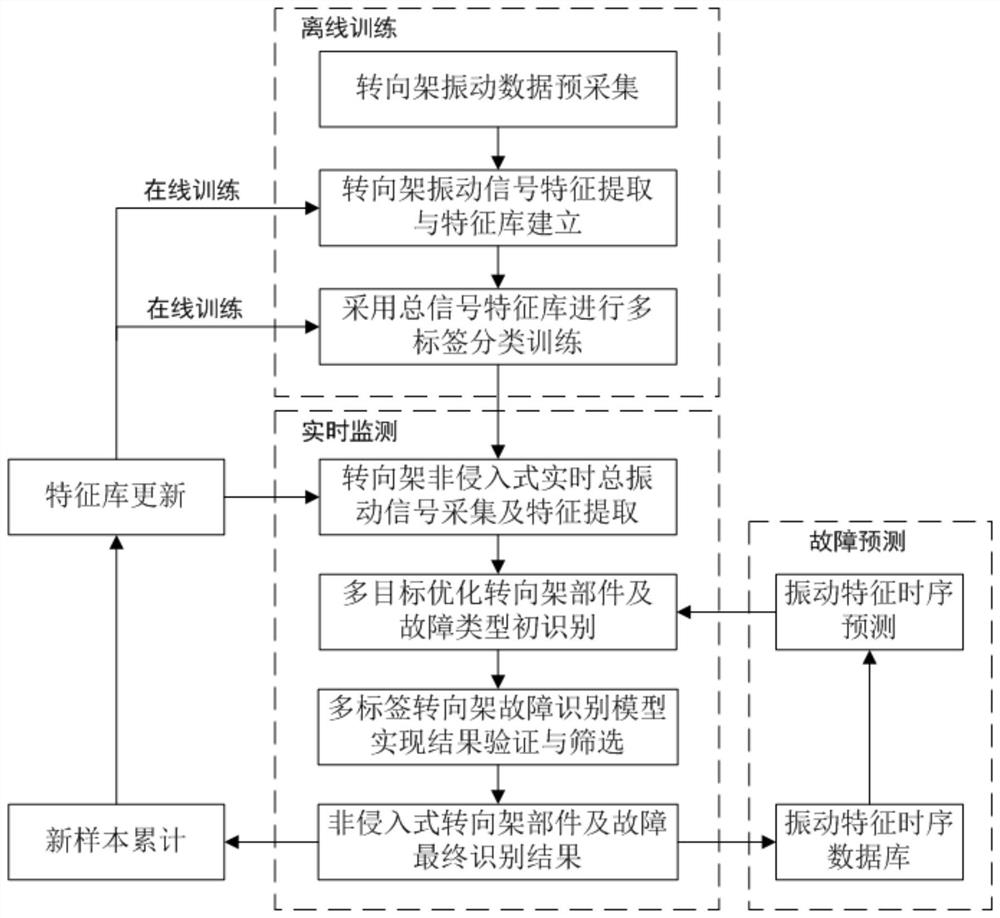

[0035] like figure 1 As shown, the non-intrusive real-time fault monitoring method for a train bogie of the present invention includes the following steps:

[0036] Step 1, intrusive pre-collection of train bogie vibration data

[0037]The bogie is the most important part of the train, and the safety and performance of the bogie determine the safety and stability of the train. The main components and fault-prone parts of the bogie include the body device, the frame, the spring shock absorber, the basic braking device and the drive mechanism. The training data required by the present invention is mainly pre-collected by the experimental method. Generally located on the frame or side frame), a vibration sensor is installed, and the vibration data of the bogie is pre-collected by changing the experimental conditions.

[0038] The specific vibration signal pre-collection scheme is as follows:

[0039] (1) Single-vibration source vibration signal acquisition, single-vibration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com