Large floating type steel structure intelligent fishery breeding net cage suitable for deep and far sea

A floating, steel structure technology, applied in application, fish farming, animal husbandry, etc., can solve the problems of high net volume loss rate, large manpower and material resource consumption, and low water exchange rate inside the cage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

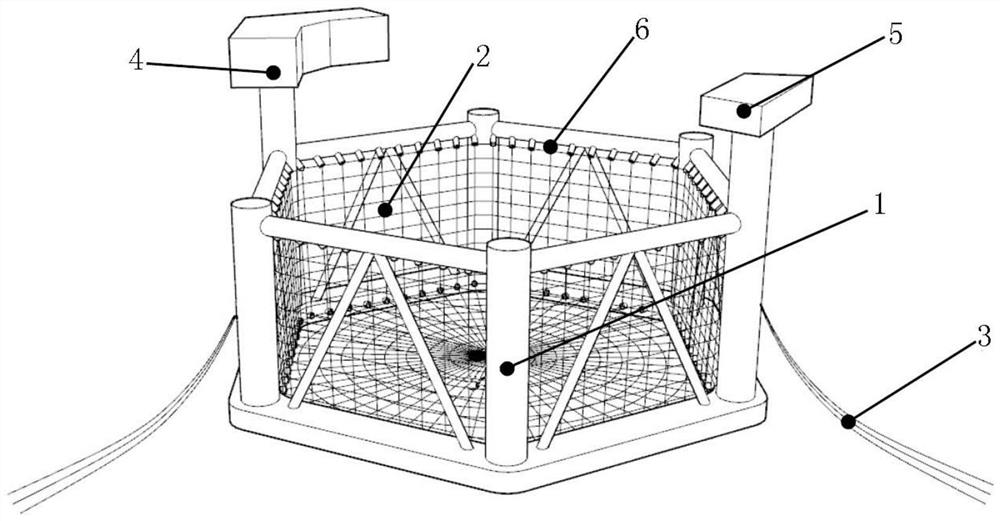

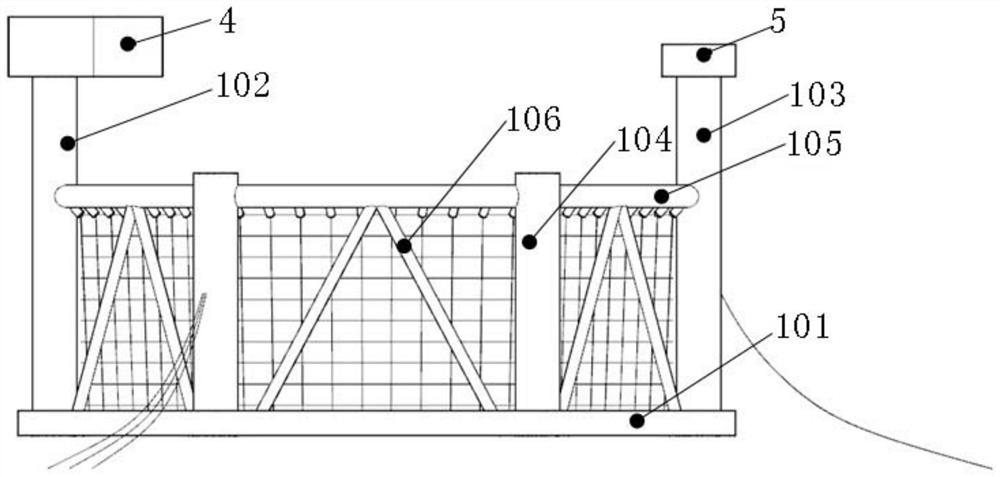

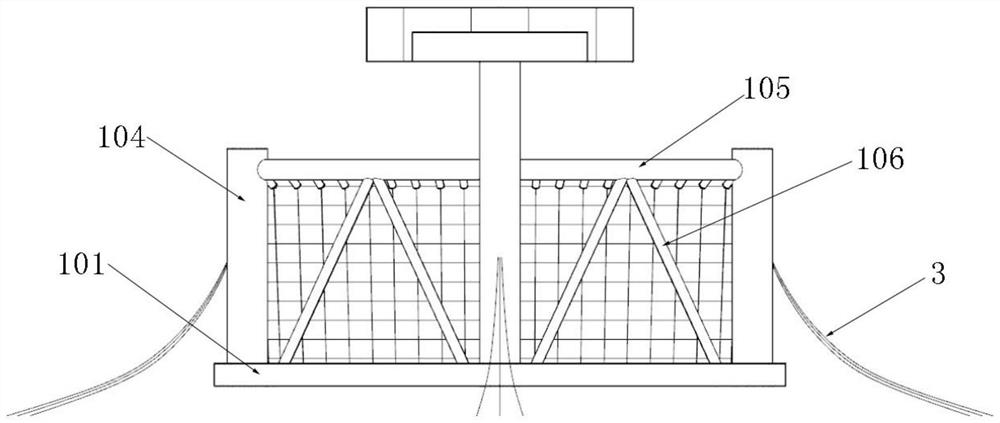

[0031] Such as Figure 1 to Figure 5 As shown, the large-scale floating steel structure intelligent fishery breeding net cage suitable for deep and open sea described in this embodiment includes a net cage main body 1, a net clothing 2, a mooring system 3, a first superstructure 4 and a second Build structure 5.

[0032]Described net cage main body 1 is a steel structure frame, and its cross section is regular hexagonal structure, comprises floating body 101, column, horizontal pipe 105 and diagonal brace 106, and described floating body 101 whole is regular hexagonal annular structure, and its cross section is Hollow rectangular structure, the floating body 101 is provided with a ballast tank inside, and the corresponding ballast system, ventilation system and sounding system are configured in the ballast tank, and the adjustment of the draft of the cage main body 1 is reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com