Production formula of concentrated feed for piglets

A technology of concentrated feed and production formula, which is applied in the field of pig feed, can solve the problems of imperfect physiological digestive system, general nutrient absorption effect, and underdeveloped stomach and intestines of piglets, etc., so as to improve taste and palatability, maintain intestinal health, and enhance The effect of growing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

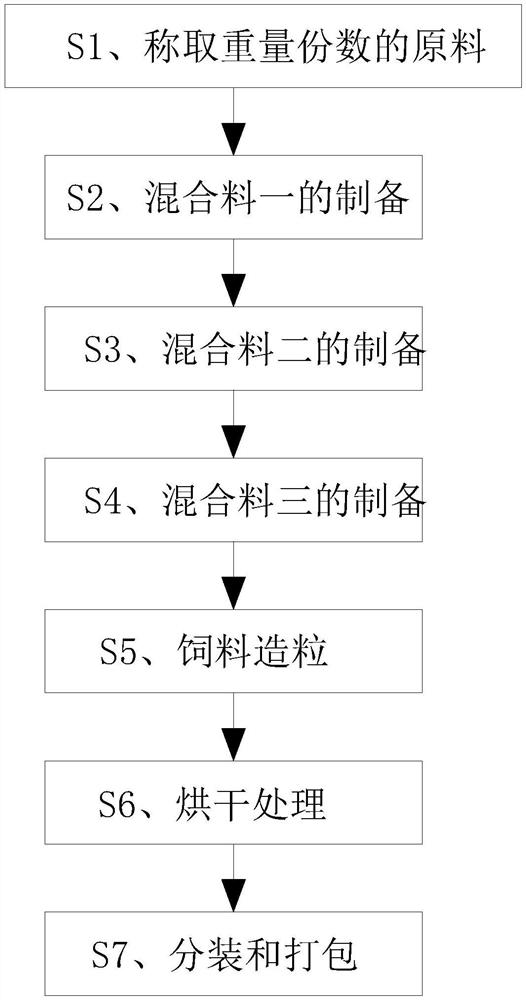

[0025] Please refer to figure 1 As shown, the invention discloses a production formula of concentrated feed for piglets, comprising the following steps:

[0026] S1. Raw materials in parts by weight: 17 parts of puffed corn flour, 5 parts of puffed soybean powder, 10 parts of wheat bran, 8 parts of soybean meal, 4 parts of rice bran meal, 5 parts of fermented rice husk powder, 2 parts of compound trace elements, 2 parts of acid enzyme, 1 part of stone powder, 0.5 part of calcium hydrogen phosphate, 0.9 part of table salt, 0.2 part of lysine, 0.4 part of calcium hydrogen phosphate, 2 parts of cysteine, 1 part of calcium hydrogen phosphate, 5 parts of compound enzyme and 3 parts vegetable oil.

[0027] S2. Preparation of Mixture 1: Mix and pulverize the wheat bran, soybean meal and rice bran meal in step S1 in proportion, and pass through a sieve for screening to obtain the required Mixture 1 for later use;

[0028] S3, preparation of mixture 2: add puffed corn flour and puffe...

Embodiment 2

[0034] Please refer to figure 1 As shown, the invention discloses a production formula of concentrated feed for piglets, comprising the following steps:

[0035] S1. Raw materials in parts by weight: 18 parts of puffed corn flour, 7 parts of puffed soybean powder, 11 parts of wheat bran, 5 parts of soybean meal, 3 parts of rice bran meal, 5 parts of fermented rice husk powder, 3 parts of compound trace elements, 1-2 parts of acid enzyme, 1 part of stone powder, 1 part of calcium hydrogen phosphate, 0.8-1 part of table salt, 0.2 parts of lysine, 1.2 parts of calcium hydrogen phosphate, 1 part of cysteine, 2 parts of calcium hydrogen phosphate, compound enzyme 3 parts of agent and 4 parts of vegetable oil.

[0036] S2. Preparation of Mixture 1: Mix and pulverize the wheat bran, soybean meal and rice bran meal in step S1 in proportion, and pass through a sieve for screening to obtain the required Mixture 1 for later use;

[0037] S3, preparation of mixture 2: add puffed corn fl...

Embodiment 3

[0043] Please refer to figure 1 shown, please refer to figure 1 As shown, the invention discloses a production formula of concentrated feed for piglets, comprising the following steps:

[0044] S1. Raw materials in parts by weight: 20 parts of puffed corn flour, 10 parts of puffed soybean powder, 12 parts of wheat bran, 8 parts of soybean meal, 4 parts of rice bran meal, 5 parts of fermented rice husk powder, 3 parts of compound trace elements, 2 parts of acid enzyme, 1 part of stone powder, 1 part of calcium hydrogen phosphate, 1 part of table salt, 0.6 parts of lysine, 1.2 parts of calcium hydrogen phosphate, 2 parts of cysteine, 3 parts of calcium hydrogen phosphate, 5 parts of compound enzyme and 5 parts of vegetable oil.

[0045] S2. Preparation of Mixture 1: Mix and pulverize the wheat bran, soybean meal and rice bran meal in step S1 in proportion, and pass through a sieve for screening to obtain the required Mixture 1 for later use;

[0046] S3, preparation of mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com