Polymerization reaction method for carbon fibers and equipment thereof

A polymerization reaction, carbon fiber technology, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc. Insufficient capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples.

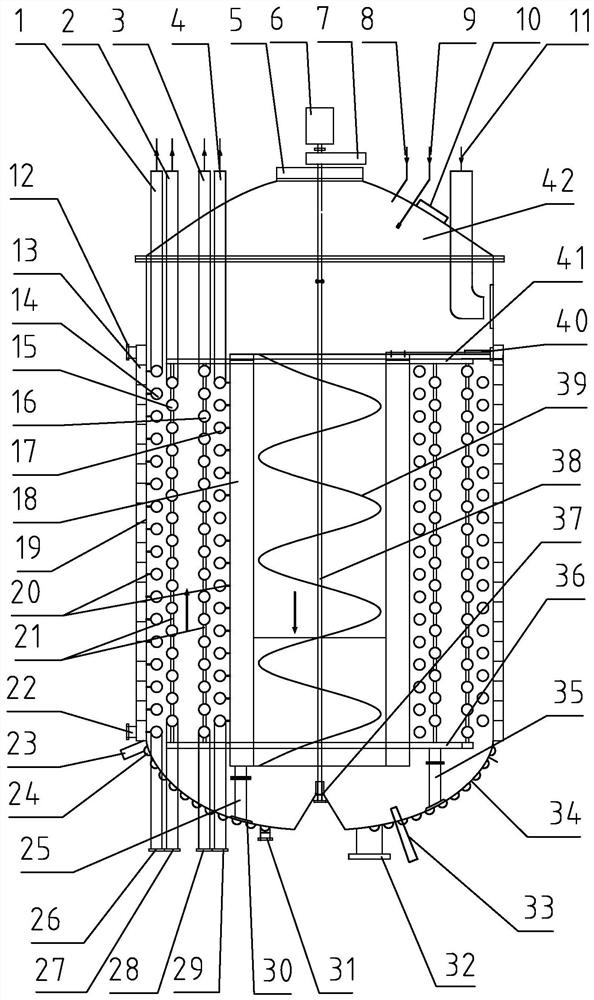

[0029] Such as figure 1 As shown, a kind of carbon fiber polymerization reaction equipment is provided with a reaction kettle 19, an upper head 42 is arranged above the reaction kettle 19, a stirring port 5 is arranged on the upper head 42, and a radar liquid level is also arranged on the upper head 42. Meter and sight glass 10, under the reaction kettle 19 is provided with a lower head 34, on the lower head 34 is provided with a thermal resistance thermometer 33, inside the reaction kettle 19 is provided with a guide tube 18, between the reactor 19 and the guide tube 18 There is an inner coil, the inner coil is a bottom-in and top-out structure, a propeller blade 39 is arranged in the guide tube 18, a stirring shaft 38 is arranged on the propeller blade 39, and a driving device is arranged on the top of the stirring shaft 38, and the driving device includes a motor and Reducer 7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com