Bionic curved surface shear knife

A technology of shearing knives and curved surfaces, used in shearing devices, tools for shearing machines, maintenance and safety accessories, etc., can solve the problems of easy wear and large tool load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

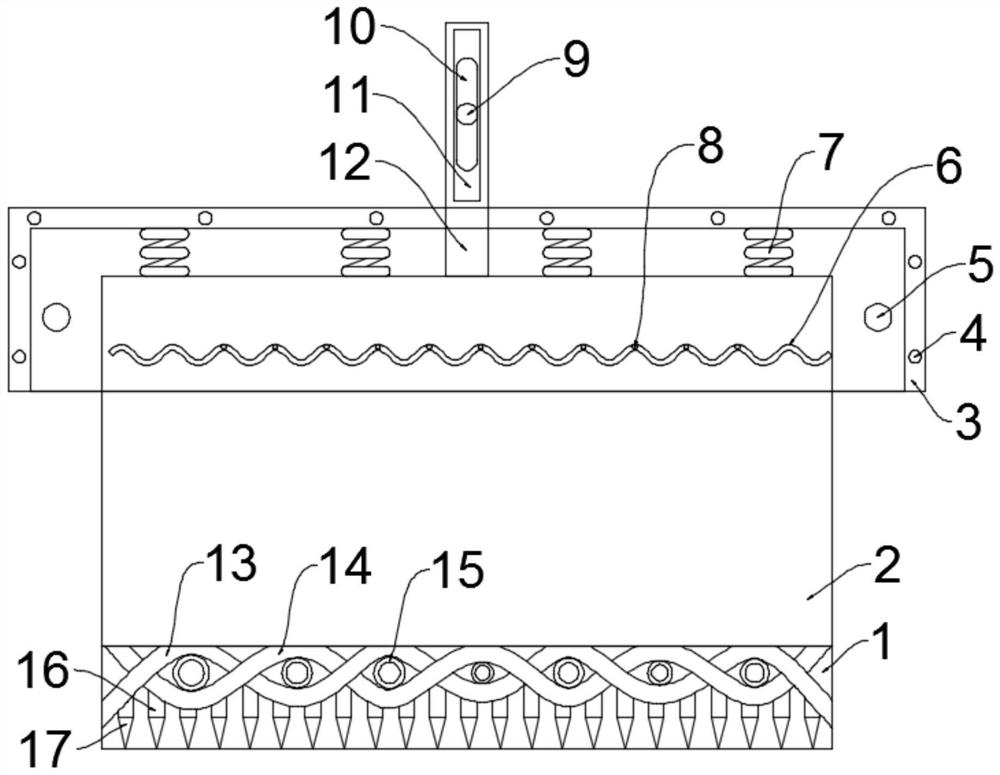

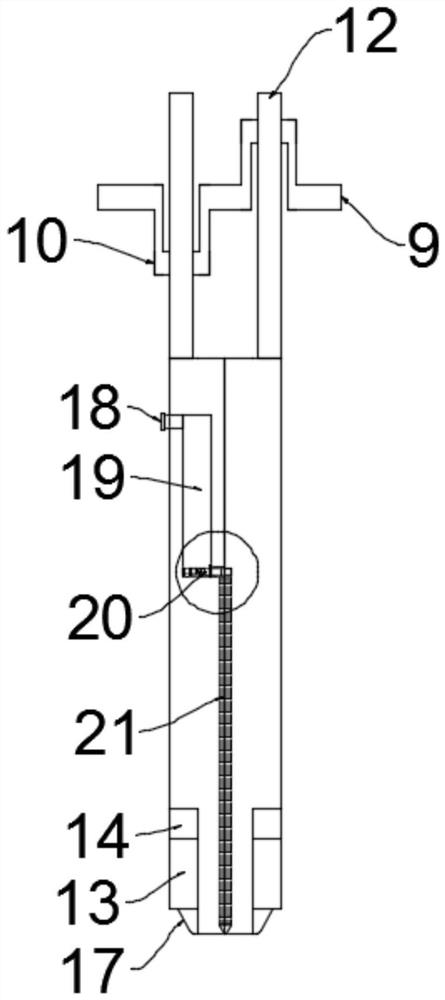

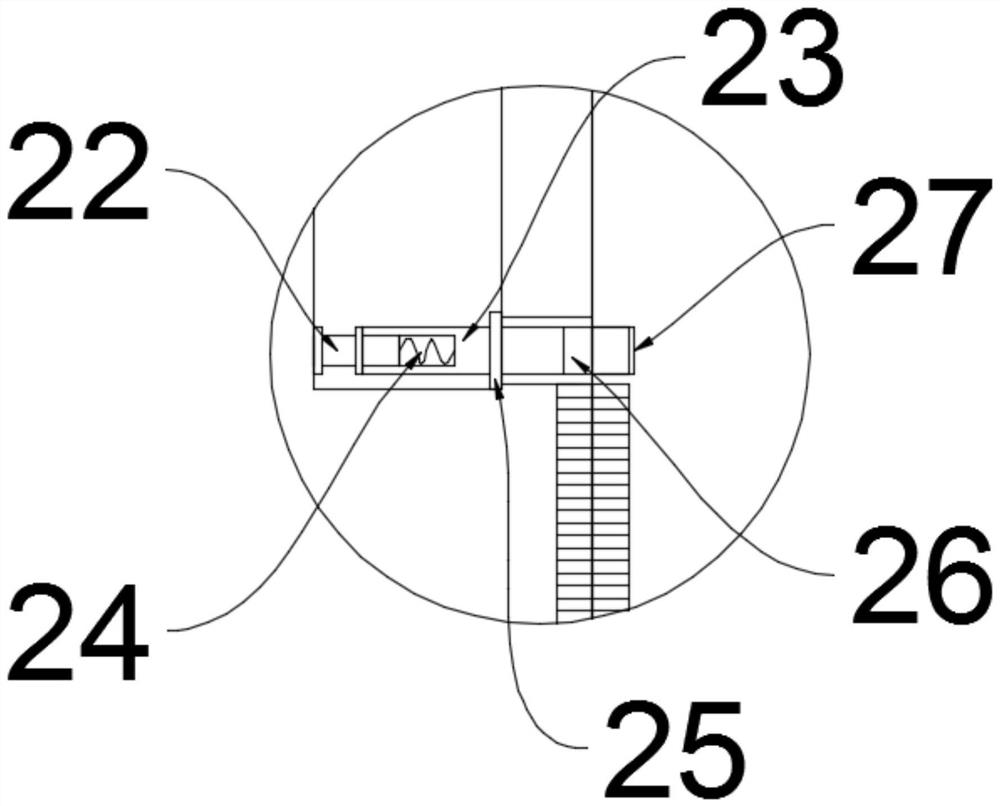

[0027] see Figure 1~4 , in an embodiment of the present invention, a bionic curved surface shearing knife includes a knife body and an installation shell 3 for installing the knife body, the installation shell 3 is arranged on the top of the knife body, and the knife body is composed of two symmetrically arranged The tool splicing structure, further, the tool includes a knife base 1, a knife back 2 and a knife tip 17, the knife base 1 is provided with a knife back 2 on the outer wall, and the three sides of the knife back 2 are on the same level as the corresponding sides of the knife base 1. Qi, the first bionic snake-shaped strip 13 and the second bionic snake-shaped strip 14 are fixed on the knife base 1 below the knife back 2, and the first bionic snake-shaped strip 13 and the second bionic snake-shaped strip 14 are far away from the knife base 1. The surface is a curved surface, and the first bionic snake-shaped strip 13 and the second bionic snake-shaped strip 14 are al...

Embodiment 2

[0032] see Figure 5 The difference between the embodiment of the present invention and embodiment 1 is that in order to make the lubricating oil fully distributed in the length space of the entire tool, the bottom of both ends of the installation shell 3 are fixed with a shell 28, and the inside of the shell 28 A piston 31 is provided, and a push rod is fixed on one side of the piston 31 close to the cutter body. The push rod penetrates the housing 28 and contacts the side wall of the cutter body. The other side of the piston 31 and the inner wall of the housing 28 A third spring 29 is fixedly connected, and a hose 30 is connected to the side wall of the casing 28 close to the cutter body. The hose 30 is connected to the cutter body and communicates with the top of the adjacent oil flow groove 21, and the adjacent oil flow groove 21 They are connected through communication holes. When the cutter body reciprocates, the piston 31 is driven to reciprocate left and right by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com