High borosilicate glass kettle automatic nozzle leading system and control method thereof

A high borosilicate glass and glass pot technology, which is applied in glass manufacturing equipment, glass molding, glass remolding, etc. To achieve complete unity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

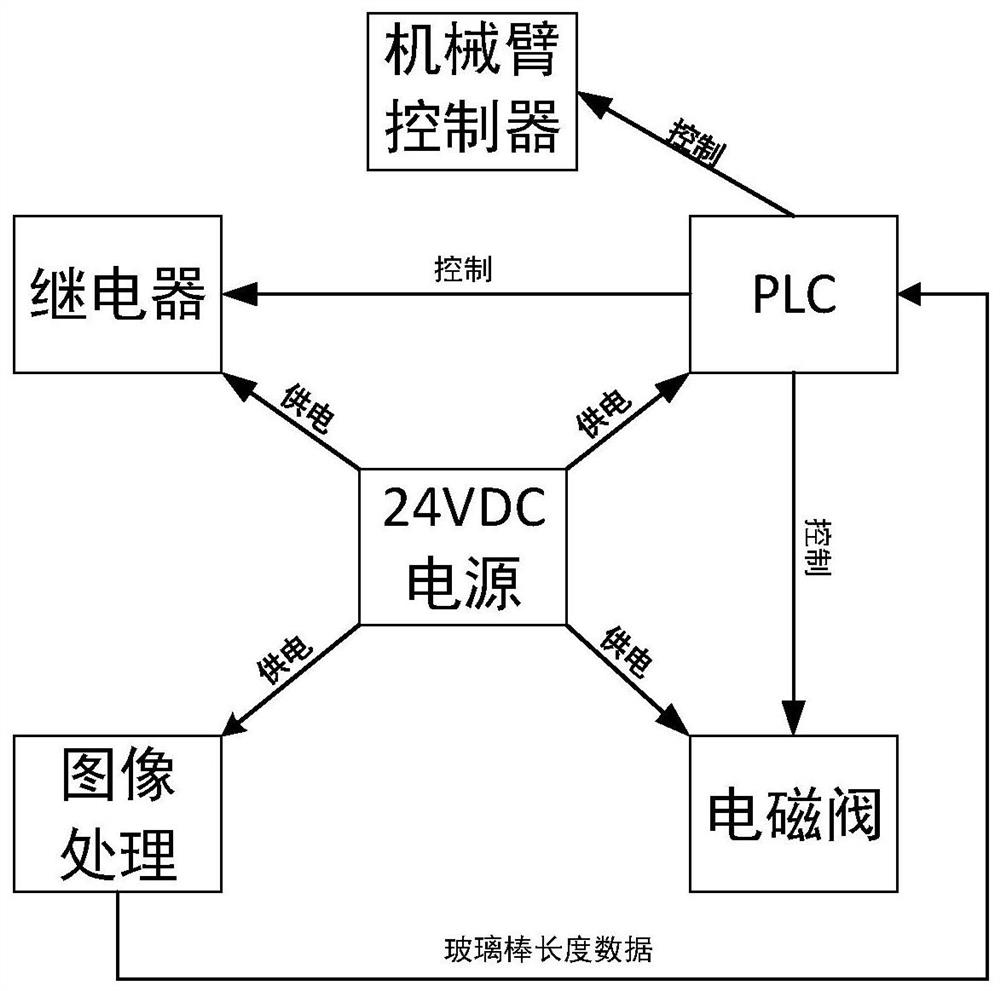

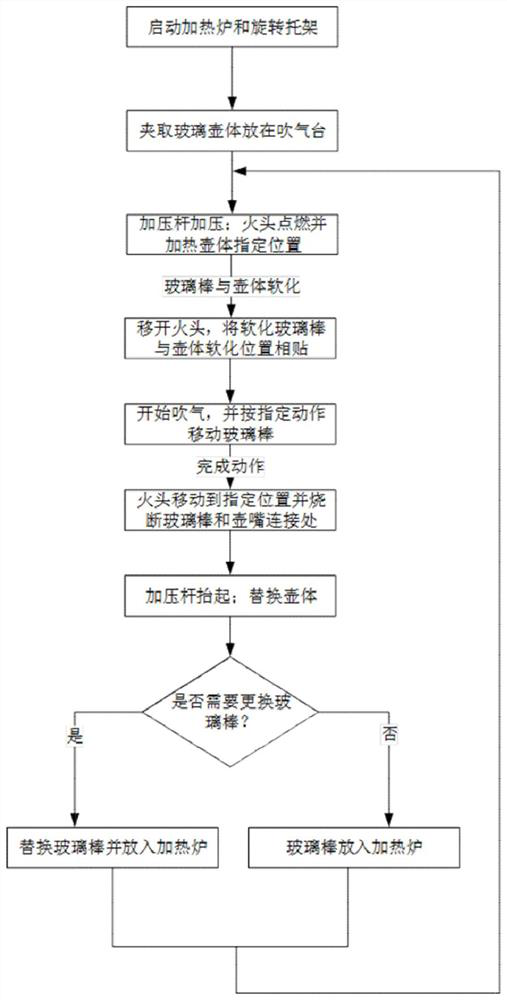

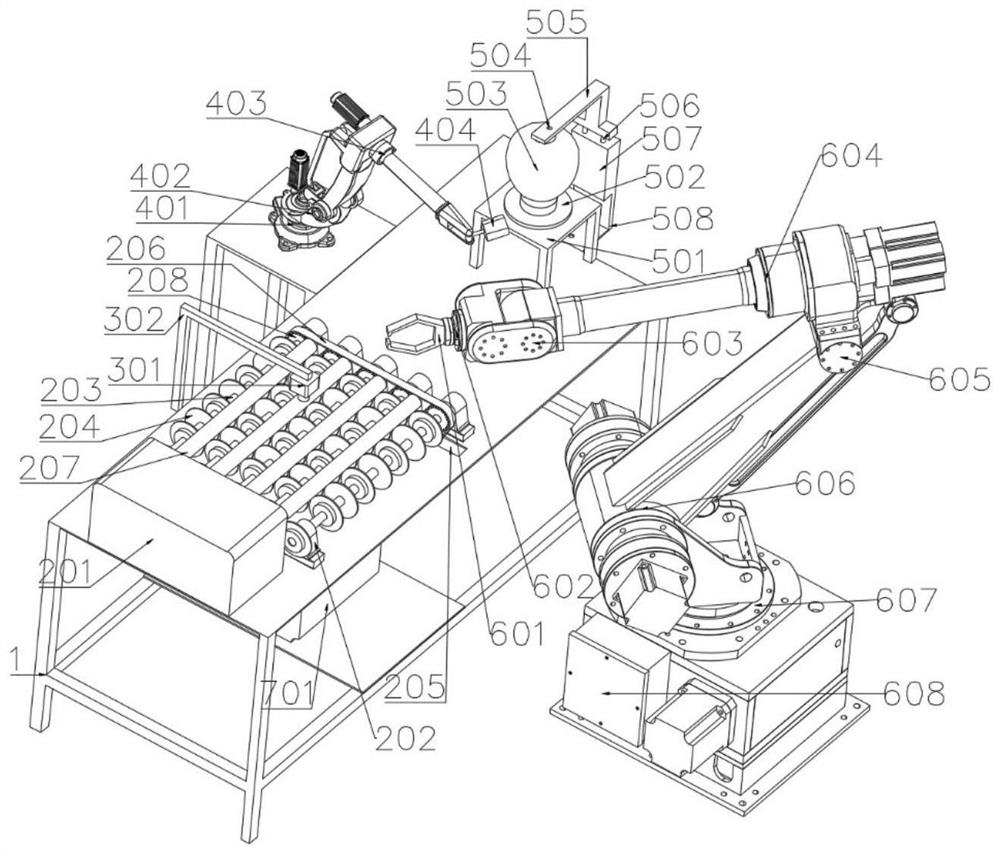

[0042] Example 1, see Figure 1-Figure 8 , a high borosilicate glass pot automatic nozzle system, including a workbench 1, a high borosilicate glass rod melting table 2, a vision system 3, a mobile fire nozzle mechanical arm 4, a high borosilicate glass pot blowing table 5, a high Borosilicate glass pot and glass rod clamping mechanical arm 6, control box 8;

[0043] The high borosilicate glass pot blowing table 5 includes a high borosilicate glass pot body support table 501, a gasket 502, and a kettle body pressurizing rod 505; the high borosilicate glass pot body support table 501 is installed at the end of the workbench 1, and Four pillars support a horizontal platform, the size of the platform is larger than the largest part of the pot body, the sealing gasket 502 is located at the center of the horizontal platform, and its diameter is larger than the mouth of the pot, the center of the horizontal platform and the sealing gasket 502 has an opening, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com