Light batten prefabricated part assembling system for foundation bearing platform

A technology of prefabricated components and foundation caps, applied in infrastructure engineering, construction, etc., can solve the problems of poor control of the accuracy of brick tire membranes, affecting construction efficiency, and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

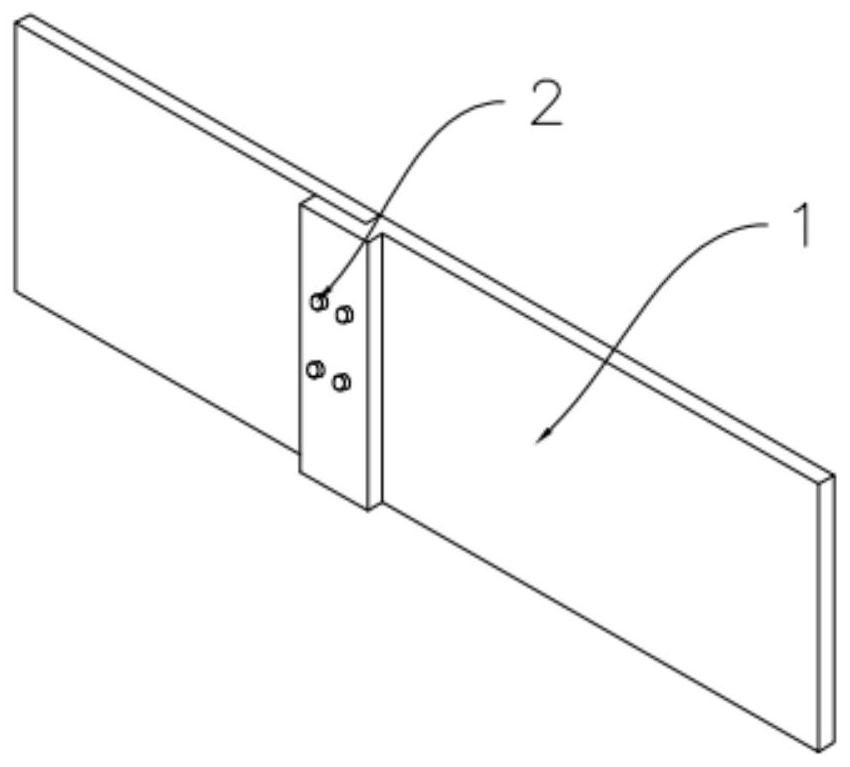

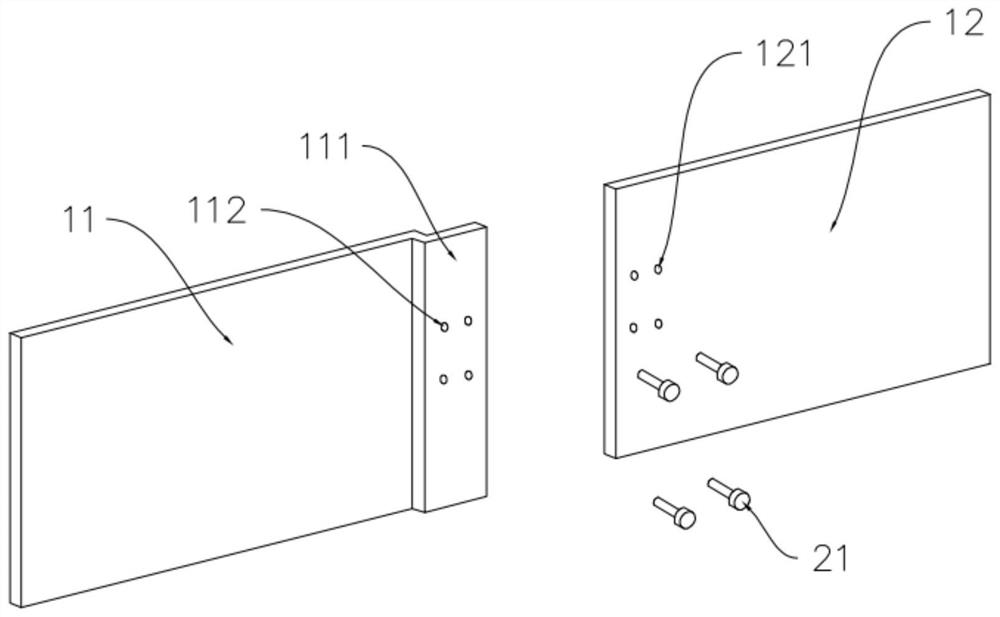

[0038] Please refer to Figure 1-2 , the prefabricated template 1 includes a connecting plate 11 and a straight plate 12, the end of the connecting plate 11 extends outwards with an L-shaped connecting block 111, and the end of the straight plate 12 is connected to the L-shaped connecting block 111 snap fit, the L-shaped connecting block 111 is provided with several first threaded holes 112, and the end of the straight plate 12 is provided with a second threaded hole 121 corresponding to the first threaded holes 112, and the bolts 21 through the first threaded hole 112 and the second threaded hole 121 for fixing.

[0039] During use, a section of the straight plate 12 is clamped in the L-shaped connecting block 111, so that the straight plate 12 and the connecting plate 11 remain parallel and on the same plane, and then the first threaded hole 112 and the second threaded hole 112 are connected by the bolt 21. The two threaded holes 121 are connected and fixed to form a long b...

Embodiment 2

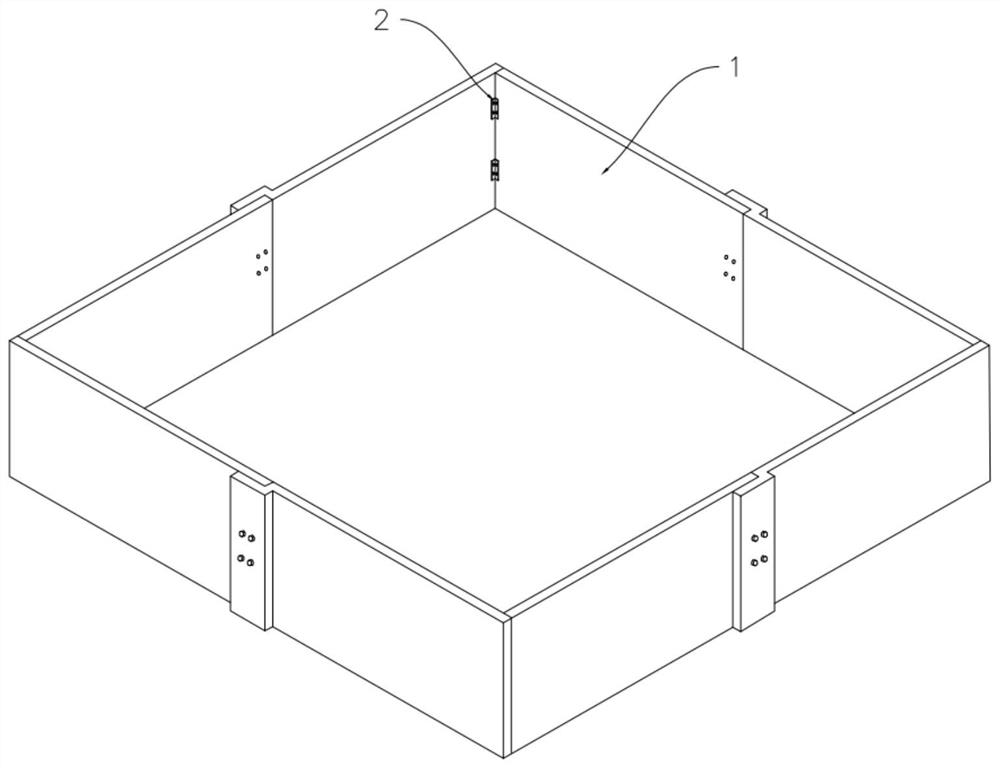

[0042] Please refer to Figure 3-4 , the ends of the prefabricated formwork 1 are connected end to end and fixed vertically to each other to form a knuckle, an L-shaped reinforcement 23 is installed at the knuckle to fit the prefabricated template 1, and bolts 21 pass through the L-shaped reinforcement 23 and prefabricated template 1 are fixed.

[0043] When in use, the ends of the two prefabricated templates 1 are vertically moved closer together and leveled, and the bottom is leveled with an adjustment wooden wedge, and then the L-shaped reinforcement 23 is connected and fixed with the prefabricated template 1 through bolts 21 to form an L-shape The module is used to build the four-corner structure of the foundation cap.

[0044] This bolt connection fixing method is suitable for the construction of large caps. The bolt connection effect is more stable, and the L-shaped reinforcement can further strengthen the structural stability, and can better avoid the deformation of th...

Embodiment 3

[0046] Please refer to Figure 5-6 , the prefabricated template 1 includes a third fixing plate 15 and a fourth fixing plate 16, the end of the third fixing plate 15 is provided with a bump 151 parallel to the third fixing plate 15, the fourth fixing plate 15 An end portion of the plate 16 is provided with a through hole 161 perpendicular to the fourth fixing plate 16 , and the protrusion 151 and the through hole 161 correspond to each other and are embedded and connected. The connection between the protrusion 151 and the through hole 161 is tightened and fixed by a wooden wedge 22 .

[0047] When in use, the four-sided modules are aligned according to the connection ports, and the protrusions 151 are directly embedded in the through holes 161. Since the planes where the protrusions 151 and the through holes 161 are located are perpendicular to each other, a formation is formed between the third fixing plate 15 and the fourth fixing plate 16 after assembly. The L-shaped modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com