Plug-and-pull longitudinal rib soundproof steel-concrete composite shear wall and its assembly method

A combined shear wall and rib type technology, applied in sound insulation, wall, insulation layer and other directions, can solve the problems of stability and on-site assembly efficiency to be improved, and achieve the effect of simplifying construction procedures, ensuring accuracy and saving working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

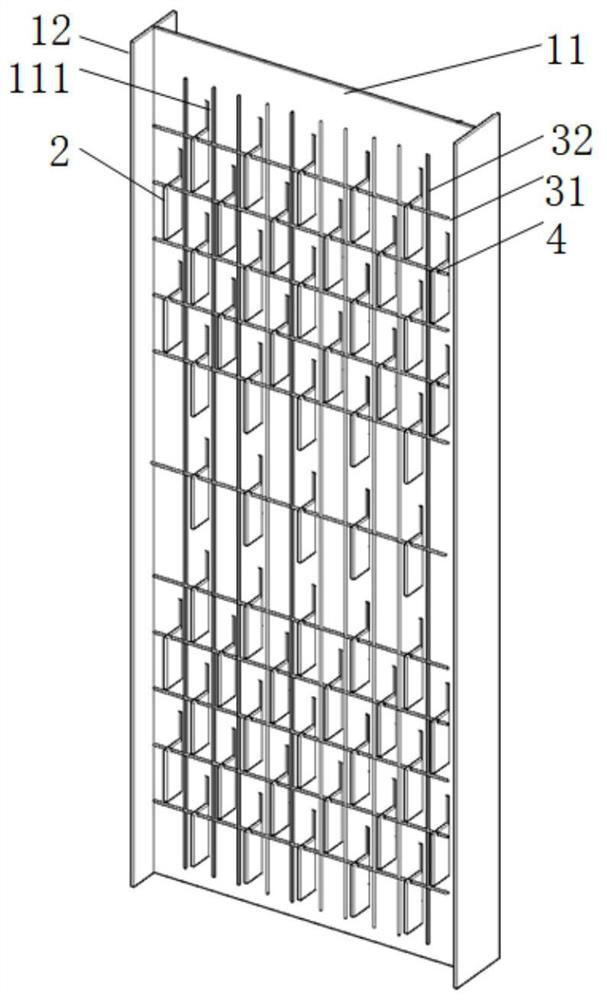

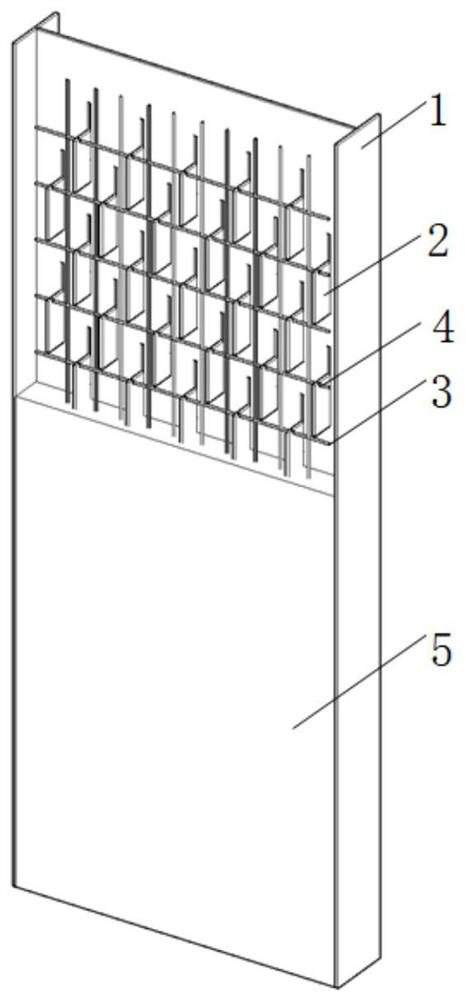

[0039] Such as Figure 1-5 As shown, a plug-in longitudinal rib soundproof steel-concrete composite shear wall includes H-shaped steel main structure 1, rib plate 2, and steel mesh 3. H-shaped steel main structure 1 includes web 11 and is symmetrically arranged on web 11. The two flanges 12 on both sides and the web 11 are arranged with multiple rows of rib plates 2 from top to bottom. The net 3 is hung on the rib plate 2 .

[0040] Vertical rectangular slots 111 are distributed on the web 11 .

[0041] The distribution of rectangular slots 111 is staggered along the vertical structure, and the distribution density of the rectangular slots 111 on the upper and lower parts of the web 11 is greater than the distribution density of the rectangular slots 111 in the middle of the web 11 .

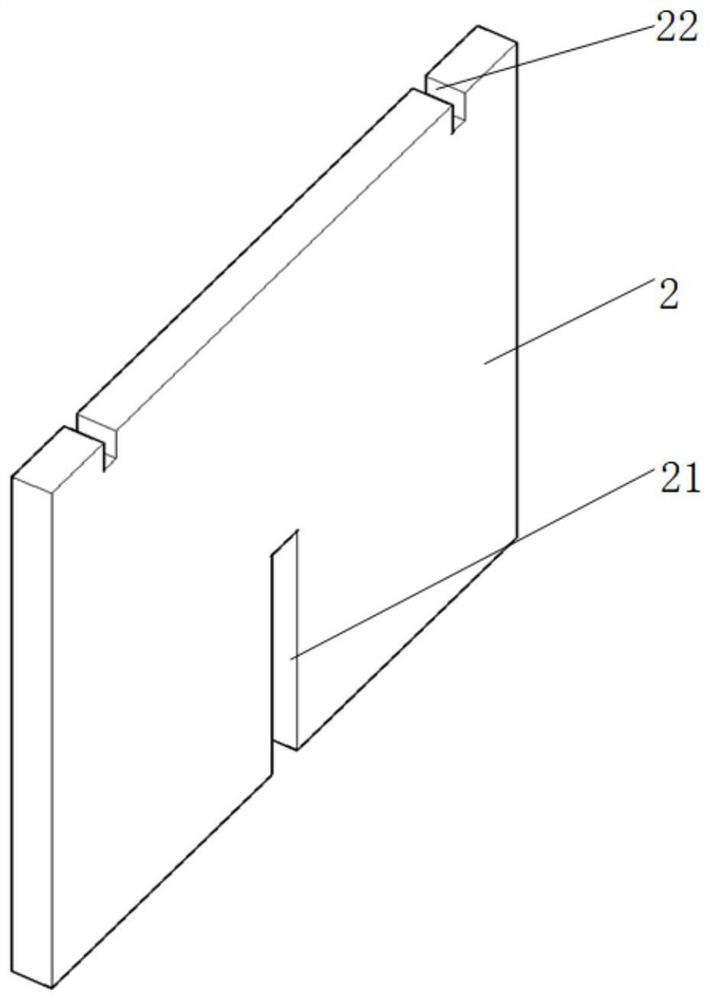

[0042] The rib plate 2 is a rectangular rib plate, the lower edge of the rectangular rib plate is vertically provided with a lower end slot 21 in the middle, and the upper edge of the rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com