Multi-redundancy locking backup mechanical lock electromechanical actuator

A technology of electromechanical actuators and mechanical locks, which is applied in the direction of electromechanical devices, mechanical equipment, electric components, etc., and can solve the problems that single-redundancy locking devices cannot meet high-safety application conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

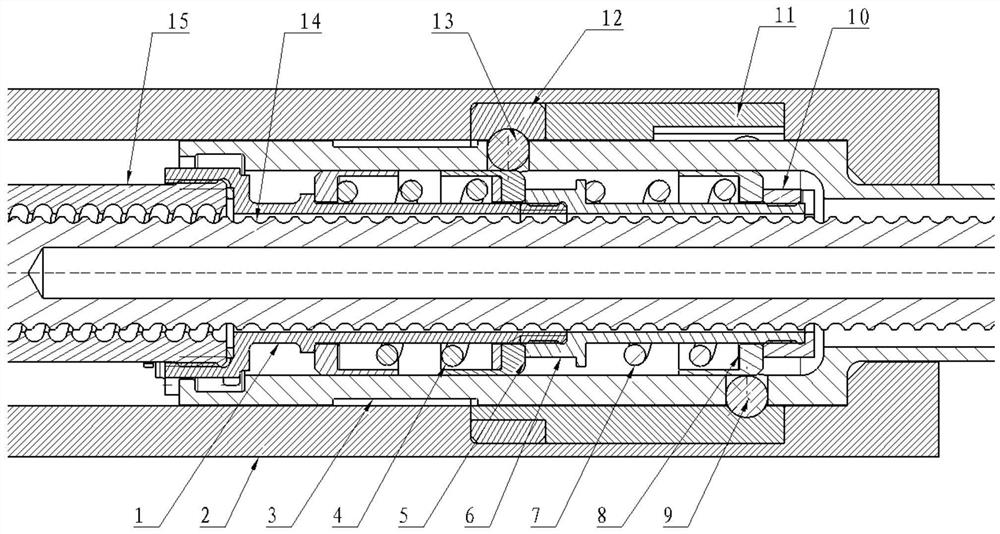

[0015] refer to figure 1 . In the preferred embodiment described below, a redundant mechanical lock structure of an electric actuator includes: a lock ring 12 that is assembled in the outer cylinder 2 to provide a locking groove and a rigid body positioned between the locking groove and the piston rod 3 The lock ball 13 between the circumferential lock holes is matched with the screw nut 15 to pass through the hollow cavity of the piston rod 3 and is fitted with the screw 14 of the sliding sleeve spring sleeve 1. The opposite symmetrical spring sliding sleeve 5 between the end faces of the spring sleeve 6, and the screw nut is constrained on the end face of the stepped hole of the sliding sleeve spring sleeve 1, and the sunken step on the stepped hole barrel is constrained to the hollow cavity port ring of the piston rod 3 on the inner side of the groove. The return lock spring 4 assembled between the two spring sliding sleeves 5 provides the locking force for the spring sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com