Electromagnetic brake rectifier test equipment and test method thereof

A technology of electromagnetic brakes and testing equipment, which is applied to parts, instruments, and measuring electronics of electrical measuring instruments, and can solve problems such as loose test pins, small elastic structures of single probes, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

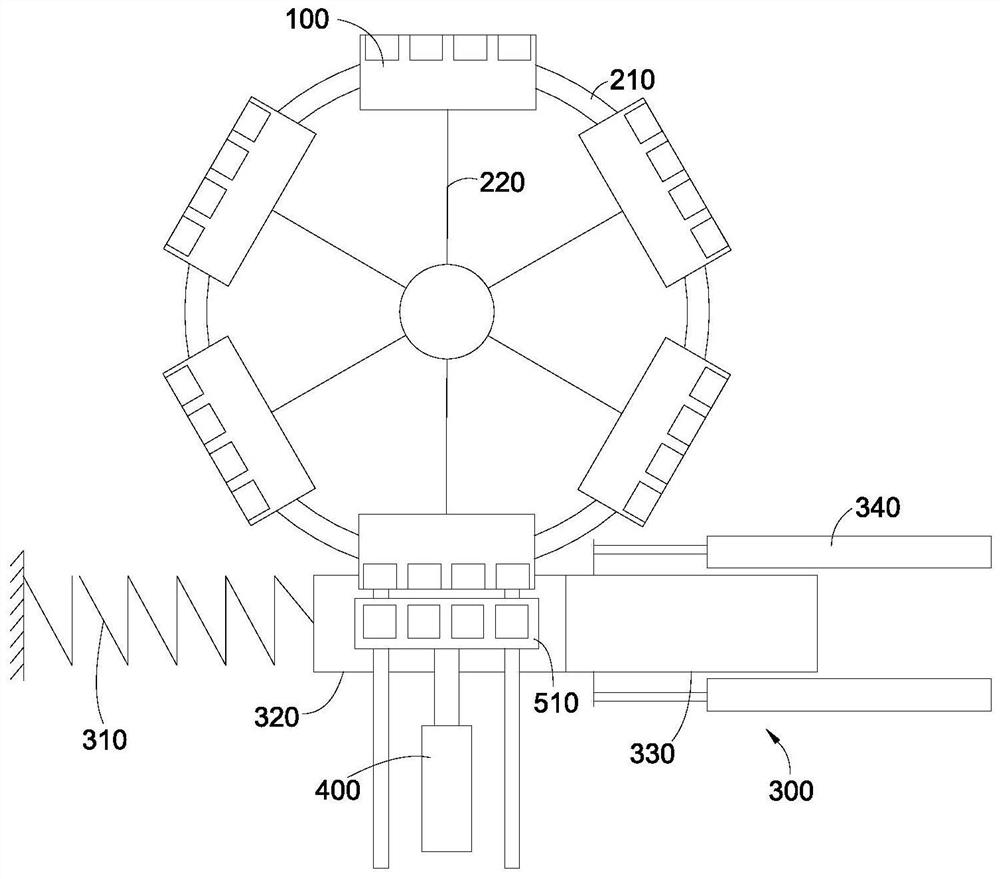

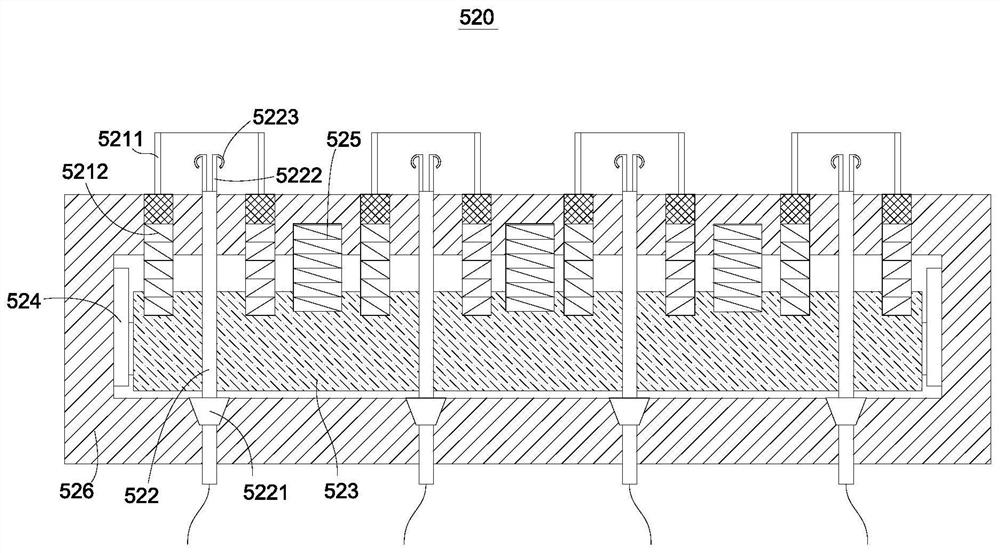

[0028] refer to Figure 1-3 , the electromagnetic brake rectifier test equipment of the present invention includes a clamping unit 100 and a test unit, the clamping unit 100 is used to clamp the rectifier, if the test process needs to be connected to the electromagnetic brake, the rectifier is connected to the electromagnetic brake, if not Connecting an electromagnetic brake also enables independent testing. The test unit contacts the detection probe 522 with the terminal of the rectifier clamped by the clamping unit 100 to realize electrical connection, that is, power-on detection, such as withstand voltage detection.

[0029] Specifically, the test unit includes a probe box 520 and a box seat 510. The probe box 520 and the box seat 510 are detachably connected. Other connection methods that are easy to disassemble are available, and the purpose is mainly to replace different test units according to rectifiers of different specifications, so as to improve the applicability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com