Rubber continuous vulcanization system

A vulcanization system and rubber vulcanization technology, applied in the field of rubber continuous vulcanization system, can solve the problems of cleaning costs, inability to handle, and increased air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

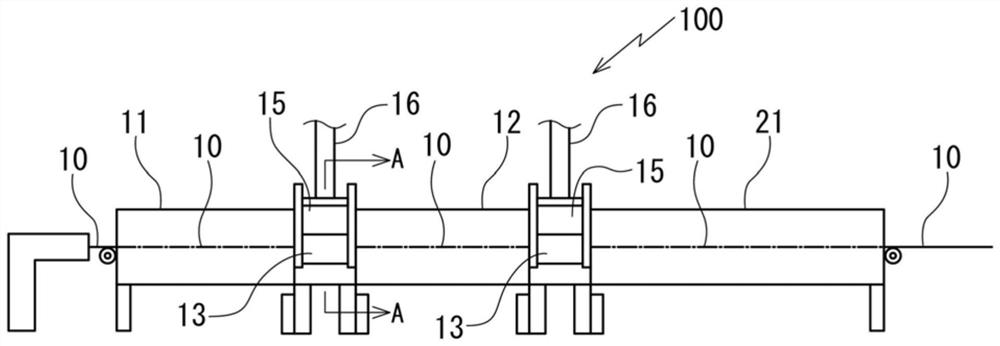

[0082] Next, a continuous rubber vulcanization system 100 according to an embodiment of the present invention will be described with reference to the drawings.

[0083] The rubber continuous vulcanization system 100 such as figure 1 As shown, a plurality of vulcanization furnaces 11 and 12 continuously arranged in series are connected by a connecting body (a cylinder in this embodiment, but not particularly limited) 13 to cover the gap between the vulcanization furnaces 11 and 12 live. The vulcanization furnaces (vulcanization tanks) 11 and 12 are microwave heating furnaces that irradiate microwaves to an object to be heated (workpiece) 10 to vulcanize. In addition, the vulcanization furnace 21 installed in series downstream of the vulcanization furnace 12 is a hot-air heating furnace that blows hot air on the workpiece 10 to vulcanize it. As the workpiece 10, for example, a weather strip for automobiles is assumed.

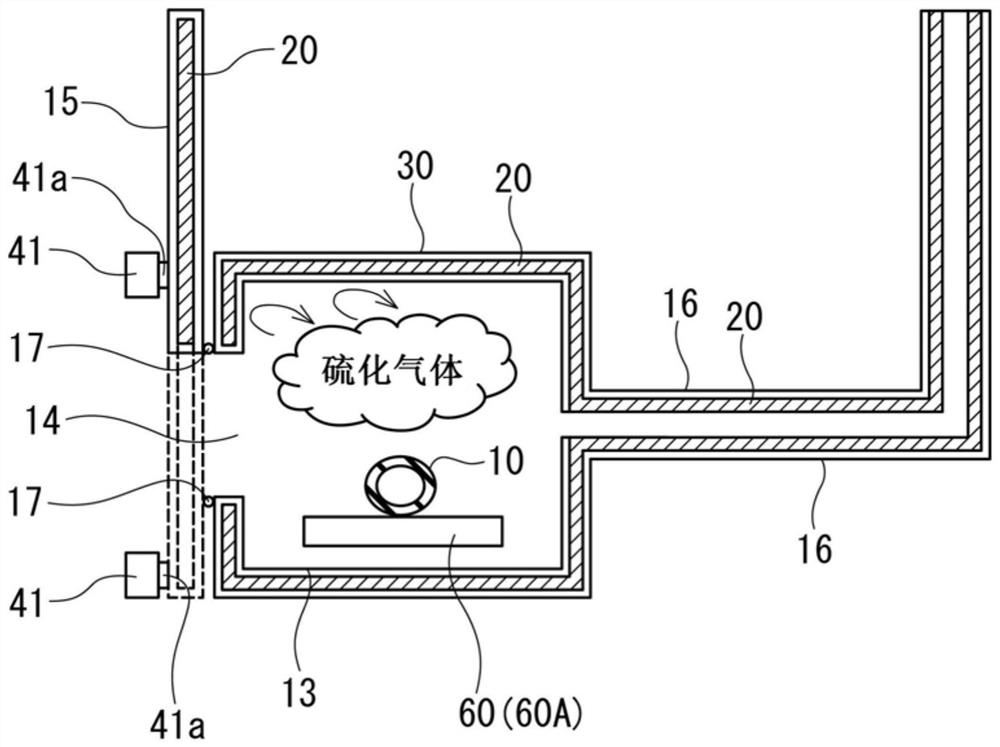

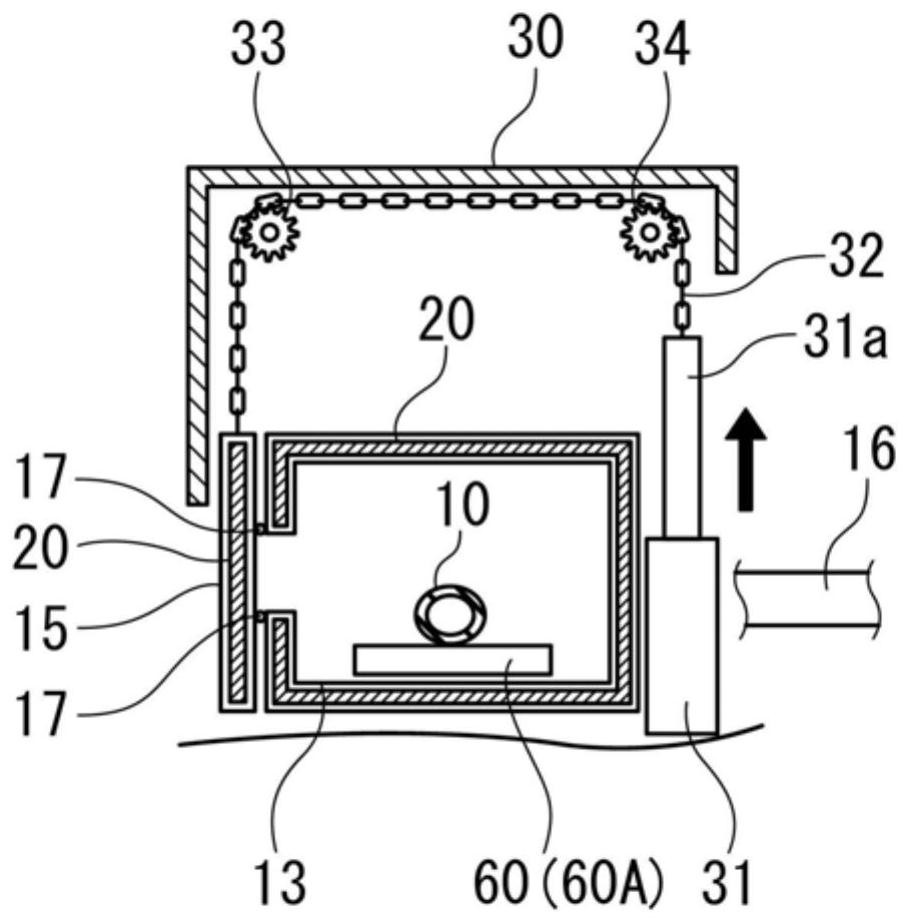

[0084] Such as figure 2 As shown, an inspection port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com