Method for preparing nadroparin calcium and dalteparin sodium

A technology of heparin sodium and low molecular weight heparin, applied in the field of low molecular weight heparin preparation, can solve the problems of poor selectivity, lower product yield, multiple cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

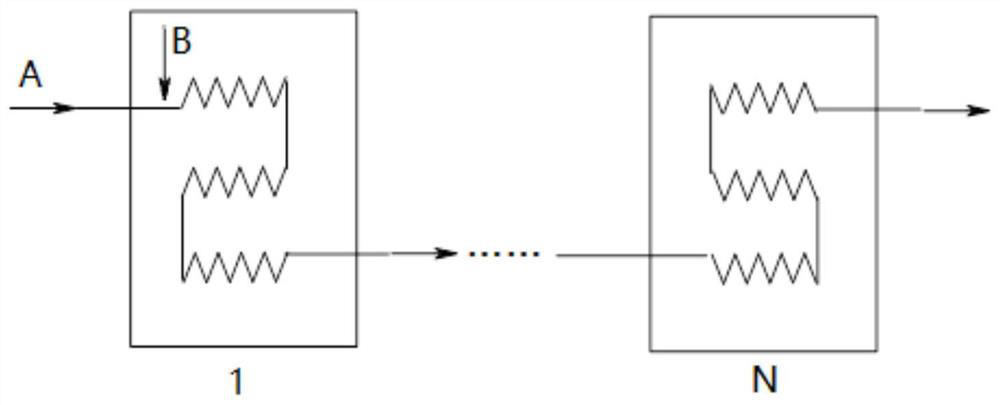

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment one nadroparin calcium

[0040] Weigh 1 kg of heparin sodium, add 3.5 kg of water to dissolve, adjust the pH to 3.0 with 2% dilute hydrochloric acid, and obtain solution A;

[0041] Weigh 24g of sodium nitrite, add 0.6kg of water to dissolve, and obtain solution B;

[0042] Add solutions A and B to the microchannel reactor from two pipelines, mix well at the inlet of the reactor, control the flow rate of solution A to 60mL / min, the flow rate of solution B to 10mL / min, and control the temperature of the reactor to 20 °C, the time for the feed liquid to flow through the reactor and carry out the cracking reaction is 30 minutes;

[0043]Collect the reaction liquid with a receiving tank at the outlet of the microchannel reactor, add sodium hydroxide solution, and maintain the pH of the receiving tank at 7.0-7.5. After receiving, add 15g of sodium borohydride and stir for 15h;

[0044] The above feed solution was adjusted to pH 3.8 with 2% di...

Embodiment 2

[0048] The preparation of embodiment dinadroparin calcium

[0049] Weigh 1 kg of heparin sodium, add 6 kg of water to dissolve, adjust the pH to 1.5 with 15% dilute hydrochloric acid, and obtain solution A;

[0050] Weigh 35g of sodium nitrite, add 0.46kg of water to dissolve, and obtain solution B;

[0051] Add solutions A and B to the microchannel reactor from two pipelines, mix well at the inlet of the reactor, control the flow rate of solution A to 650mL / min, the flow rate of solution B to 50mL / min, and control the temperature of the reactor to 45 °C, the time for the feed liquid to flow through the reactor and carry out the cracking reaction is 3 minutes;

[0052] Collect the reaction liquid with a receiving tank at the outlet of the microchannel reactor, add sodium hydroxide solution, and maintain the pH of the receiving tank at 8.0-8.5. After receiving, add 25g of sodium borohydride and stir for 20h;

[0053] The above feed solution was adjusted to pH 2.0 with 15% di...

Embodiment 3

[0057] The preparation of embodiment Sandalparin Sodium

[0058] Weigh 1 kg of heparin sodium, add 5.4 kg of water to dissolve, adjust the pH to 2.8 with 8% dilute nitric acid, and obtain solution A;

[0059] Weigh 15g of sodium nitrite, add 0.9kg of water to dissolve, and obtain solution B;

[0060] Add solutions A and B to the microchannel reactor from two pipelines, mix well at the inlet of the reactor, control the flow rate of solution A to 60mL / min, the flow rate of solution B to 10mL / min, and control the temperature of the reactor to 15 °C, the time for the feed liquid to flow through the reactor and carry out the cracking reaction is 30 minutes;

[0061] Collect the reaction liquid with a receiving tank at the outlet of the microchannel reactor, and add sodium hydroxide solution to maintain the pH of the receiving tank at about 7.5-8.0. After receiving, add 10g of sodium borohydride and stir for 10h;

[0062] Add 8% dilute nitric acid to the above feed solution to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com