Slope drainage structure and method

A drainage structure and slope technology, applied in the field of slope drainage structure, can solve problems such as easy blockage, high use cost, and long construction period of underground drainage tunnels, and achieve the effect of increased drainage flow and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

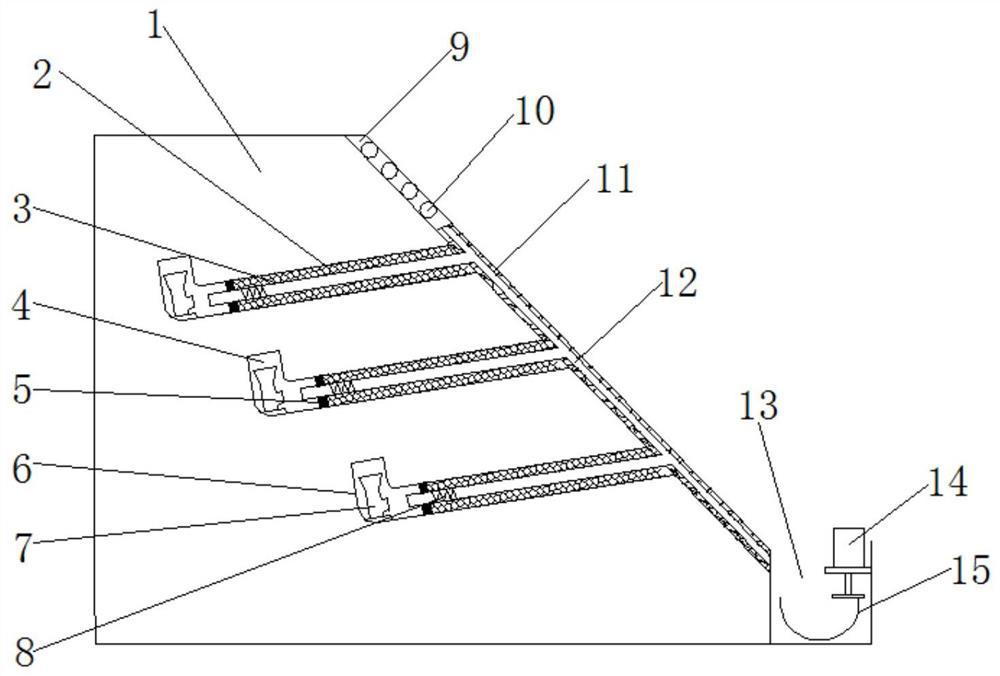

Embodiment 1

[0033]Example 1: When there is less water in the cavity of the permeable hole section 4, and the negative pressure in the cavity of the permeable hole section 4 can meet the initial condition of siphon, the accumulated water in the cavity of the permeable hole section 4 can be directly discharged through the drain pipe 12. The nozzle is naturally and actively discharged to the side ditch 13 under the action of siphon.

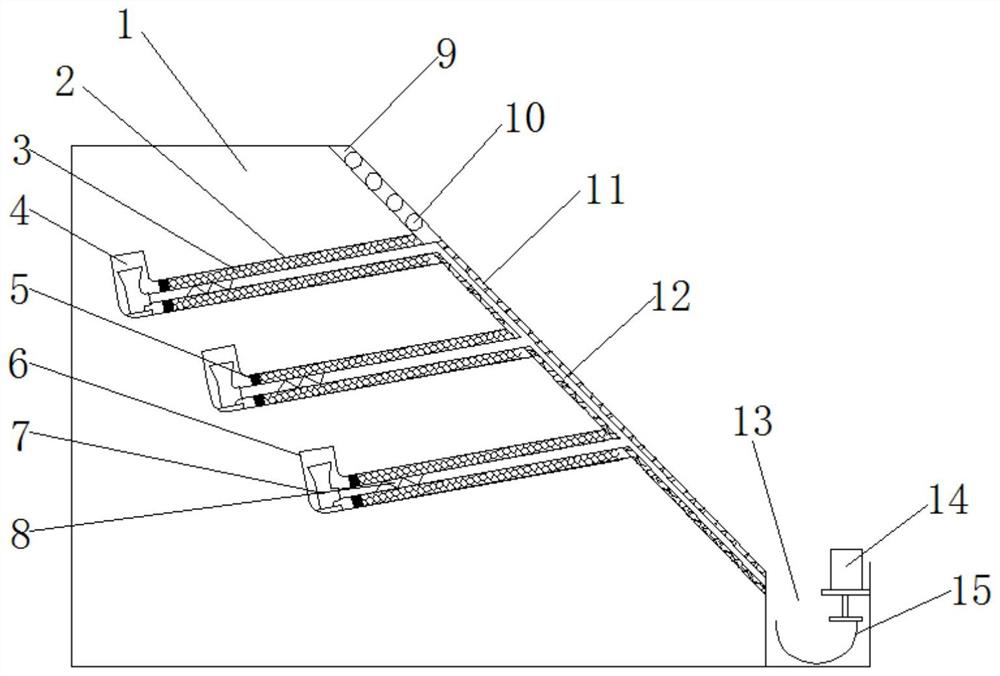

Embodiment 2

[0034] Embodiment 2: When the water content of the entire slope 1 is large, the water-absorbing swelling filler 3 fully absorbs water and expands, driving the telescopic hose section 8 to elongate, and the water inlet of the drain pipe 12 extends to the magnetic pipe 7 docking port 20, thereby passing through the magnetic pipe 7. The water inlet of the tube 7 is water, and the water inlet of the magnetic tube 7 is set in a trumpet shape to increase the water flow rate, increase the height difference between the cavity and the water outlet, and further accelerate the discharge of the water in the cavity. When the water in the cavity is reduced, the water will expand and fill The material 3 is gradually reduced, while the magnetic tube 7 and the magnetic block 5 repel each other with the same sex, and the dehydration reduction of the water-absorbing swelling filler 3 and the reduction of the flexible hose section 8 are accelerated under the action of magnetic force.

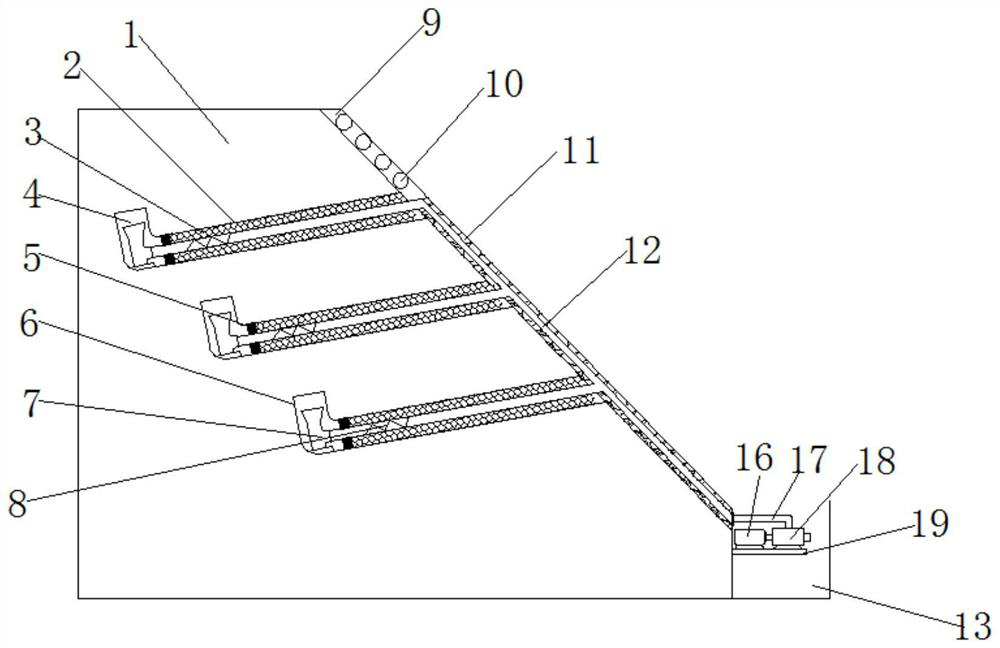

Embodiment 3

[0035] Embodiment 3: When encountering extreme weather such as continuous heavy rainfall emergency drainage, if the negative pressure of slope 1 permeable hole section 4 is insufficient to implement siphon active drainage, or a large number of air bubbles are generated in the drain pipe 12 to hinder siphon drainage, then the water pump The water inlet of 18 is connected to the water outlet of the drain pipe 12 through the water suction pipe 17, the motor 16 and the water pump 18 are turned on, and the passive pumping of the groundwater inside the slope 1 is realized through the water pump 18, and the water pump 12 can provide the initial negative pressure value of siphon drainage at the same time .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com