Tunnel full-life-cycle monitoring and early warning system and building method

A technology of full life cycle and early warning system, which is applied in the direction of earth drilling, mining equipment, mining equipment, etc., can solve the problems of difficulty in monitoring the health status of tunnel structures in the whole life cycle, difficulty in serving the full life cycle of tunnels, and inaccurate monitoring. Achieve automatic evaluation and early warning functions, efficient systems and construction methods, and ensure operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

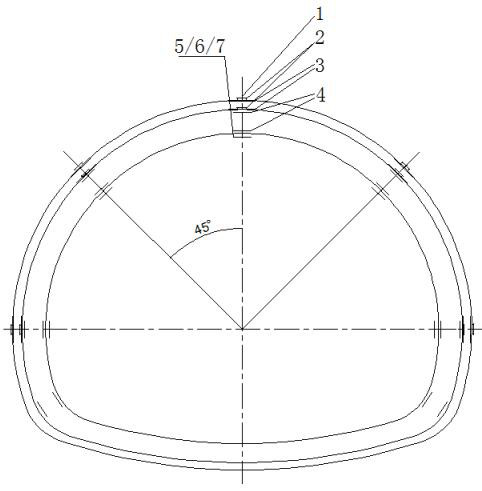

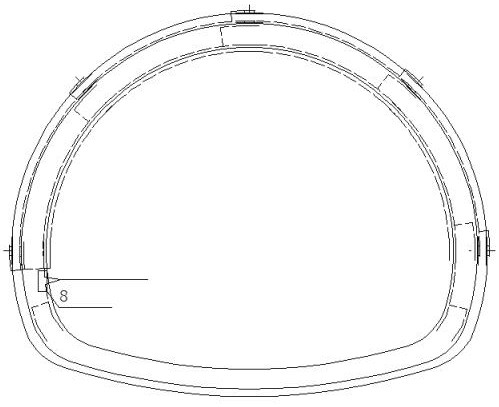

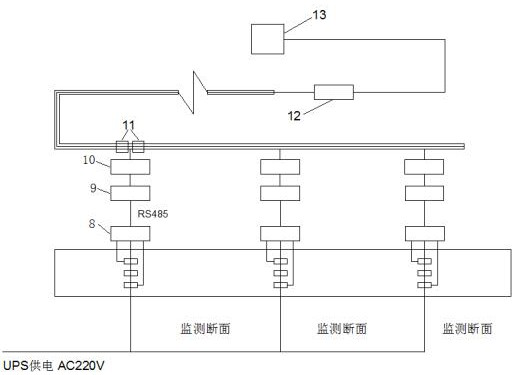

[0043] like Figure 1-Figure 4As shown, a monitoring and early warning system for the whole life cycle of a tunnel in this embodiment includes several vibrating wire sensors and fiber grating sensors installed on the upper arch ring and side walls of the tunnel monitoring section; The data acquisition device 8 that the sensor and the fiber grating sensor are connected, the data acquisition device 8 in the present embodiment adopts the data acquisition instrument that is purchased in the market and matched with the vibrating wire sensor and the fiber grating sensor, and the data acquisition device 8 is used to receive the vibration The monitoring data collected by the string sensor and the fiber grating sensor; and the data processing transmission device connected with the data acquisition device 8; the data processing transmission device includes a protocol converter 9, an optical fiber switch 10, an optical cable junction box 11, a serial port server 12; and with The data sto...

Embodiment 2

[0057] A method for establishing a monitoring and early warning system for the entire life cycle of a tunnel, comprising the following steps:

[0058] 1) The tunnel is excavated by the upper and lower steps method, and the advanced pipe shed support is firstly applied. Then excavate the excavation part of the upper step of the tunnel, and immediately after the excavation, the steel mesh is laid and the steel arch frame is set up. At this point, the water pressure gauge, earth pressure cell and steel bar gauge can be installed. Install 2 parts. First drill a hole inside the surrounding rock with a diameter of 4cm and a depth of 20cm. After wrapping the bottom of the water pressure gauge with a geotextile, insert it into the drilled hole and fix it; the earth pressure box is welded and fixed on the back of the arch and is in contact with the surrounding rock; the steel bar gauge is welded Fixed on the inside of the flanges on both sides of the arch. The sensor is routed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com