Coal mine tunnel rock wall deformation monitoring device

A deformation monitoring, coal mine roadway technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inconvenience, increase the use cost of the device, interference of precision electronic components, etc., and achieve the effect of simple installation and use, easy mobile use, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

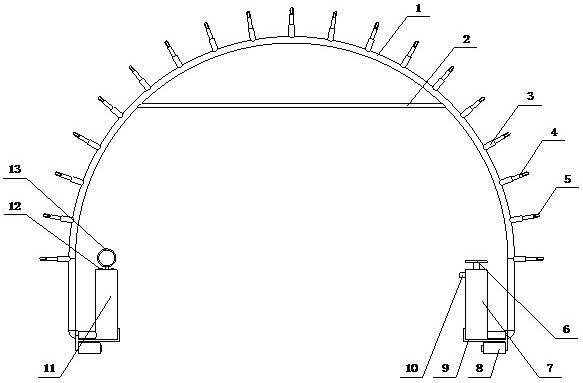

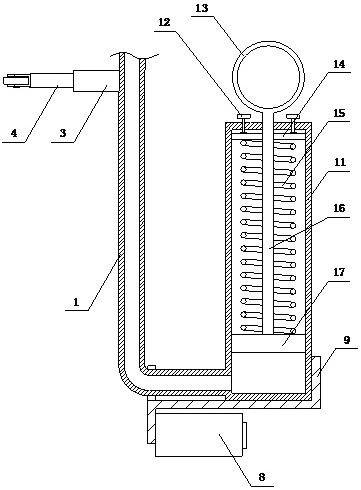

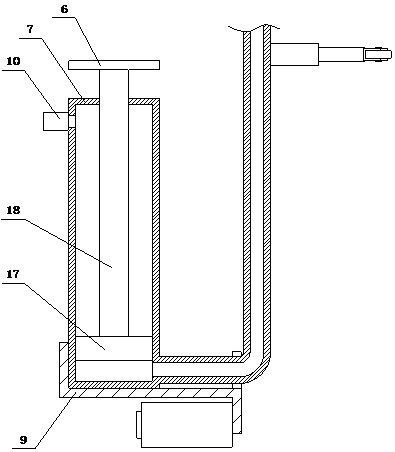

[0021] A coal mine roadway rock wall deformation monitoring device of the present invention is realized in this way. It is composed of a supporting device, a supporting device, a flushing device and a warning device. The supporting device is composed of a connecting pipe frame (1), a supporting rod (2), a fixed Pipe (3), sliding rod (4), roller (5), wheel frame (19) and return spring (20), the connecting pipe frame (1) is composed of a vertical rod and a semicircular rod, and one end of the two vertical rods is respectively It is placed on both ends of the semicircular rod and communicated with the inside of the semicircular rod. The other end of the vertical rod is bent toward the inside of the semicircular plate to form a bending part. The inside of the bending part cooperates with the inside of the semicircular rod to form a storage In the water channel, both ends of the support rod (2) are placed on the semicircular rod, and are respectively close to the two ends of the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com