Cooling and curing device for inner box body of diaphragm gas meter

A membrane gas meter, cooling and solidification technology, applied in measuring devices, liquid/fluid solid measurement, instruments, etc., can solve the problems of heavy labor, accelerated glue solidification speed, and long solidification time. The effect of curing speed, reducing labor intensity and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

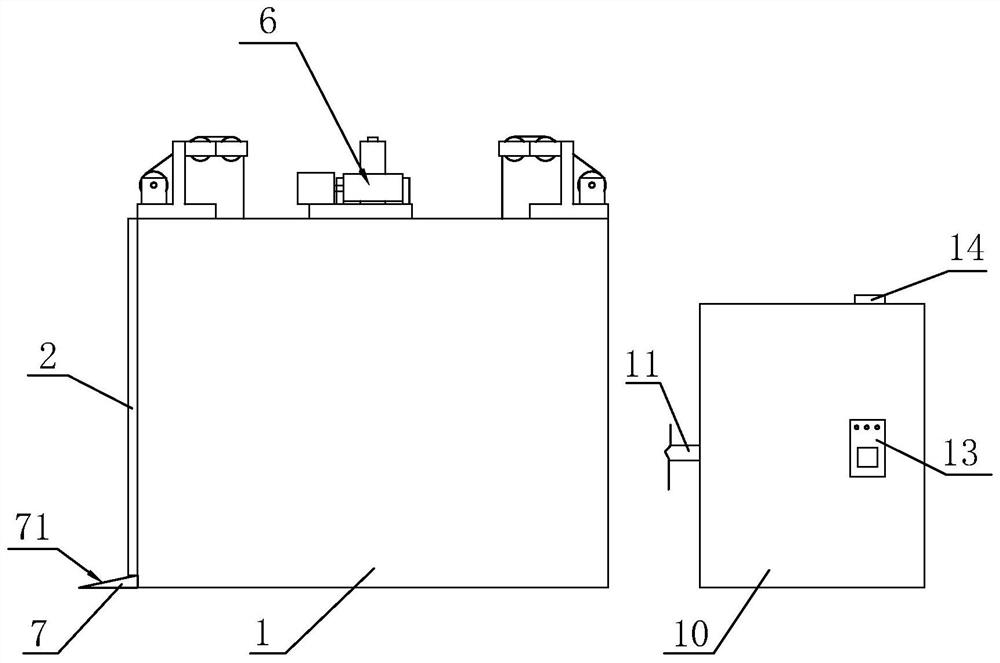

[0022] like figure 1 As shown, a cooling and solidification device for the inner box of a membrane gas meter includes a cooling and solidification chamber 1, a working chamber with one side open is formed in the cooling and solidification chamber 1, and a door is arranged at the opening of the cooling and solidification chamber 1 2. When the door body 2 is closed, the door body 2 and the cooling and solidification chamber 1 form a closed structure. If the inner box body coated with glue is placed in the working chamber, because some glue has a certain temperature when it is just applied, The cooling and curing chamber 1 cools the inner box body to speed up the curing speed of the glue.

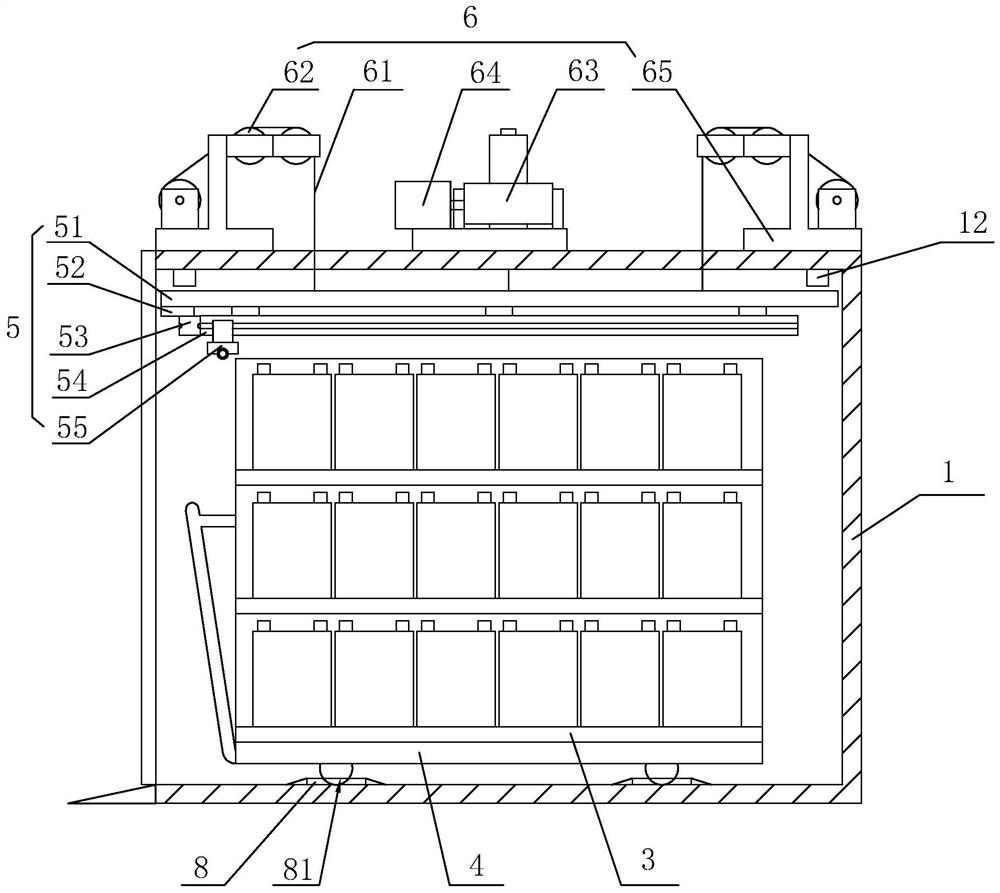

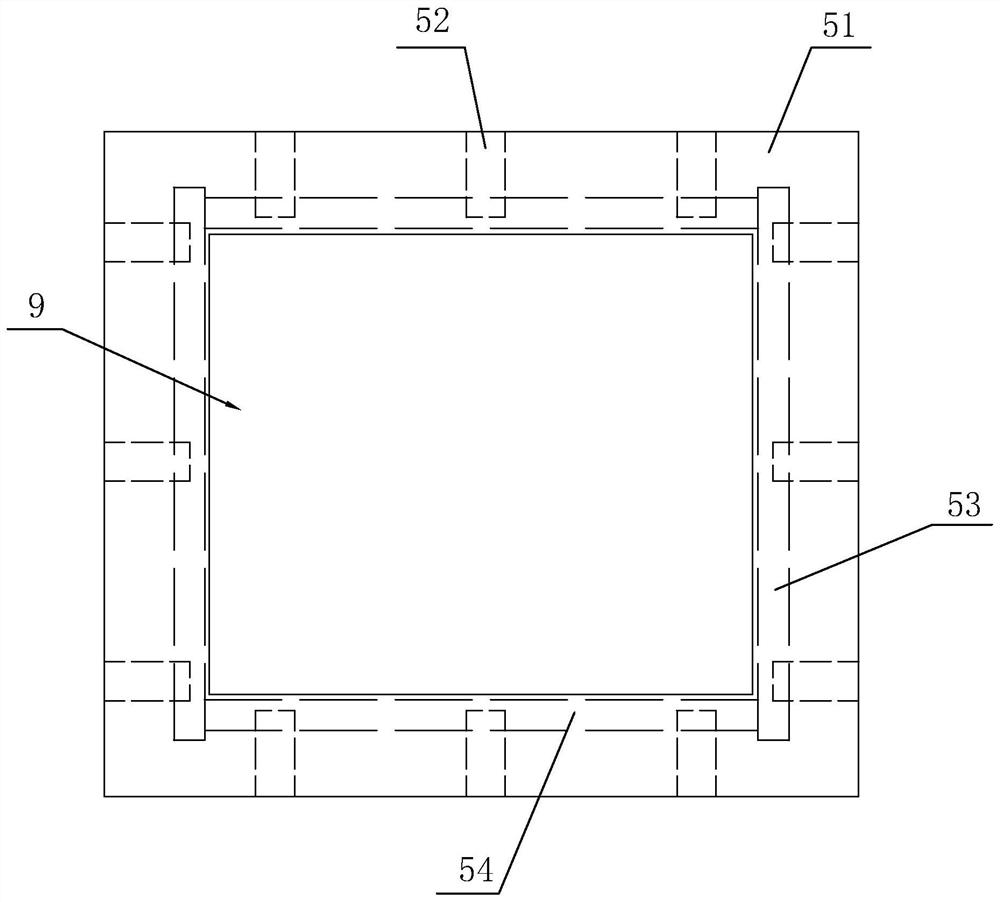

[0023] like figure 2 As shown, the cooling and fixing device also includes an inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com