Multifunctional gas component cyclic change and cyclic detection device

A gas composition and cycle detection technology, which is applied in the direction of using catalysis for chemical analysis, etc., to achieve the effect of rich functions, reduction of raw materials and waste gas, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Example 1: Introduction to the types and functions of device components

[0037] The components of this device can be divided into four categories and eight types, specifically:

[0038] Reaction component (1): includes one reactant carrier component (1-1), which has the function of carrying out the reaction. When using this device, two components need to be selected and loaded in the shell component (2) respectively.

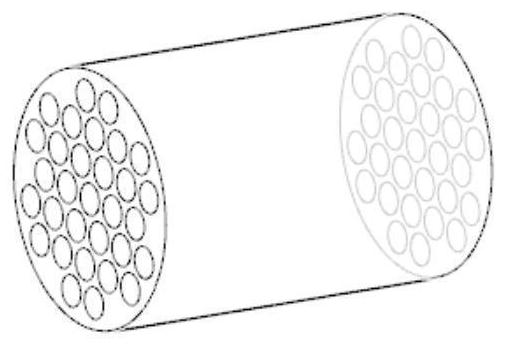

[0039] Reactant carrier component (1-1): It has a variety of internal structures and can be loaded with various reactants. It has a unique shape and can be loaded in the normal temperature shell assembly (2-1), the heat preservation shell assembly (2-2), and the temperature adjustment shell assembly (2-3). have the effect of reacting.

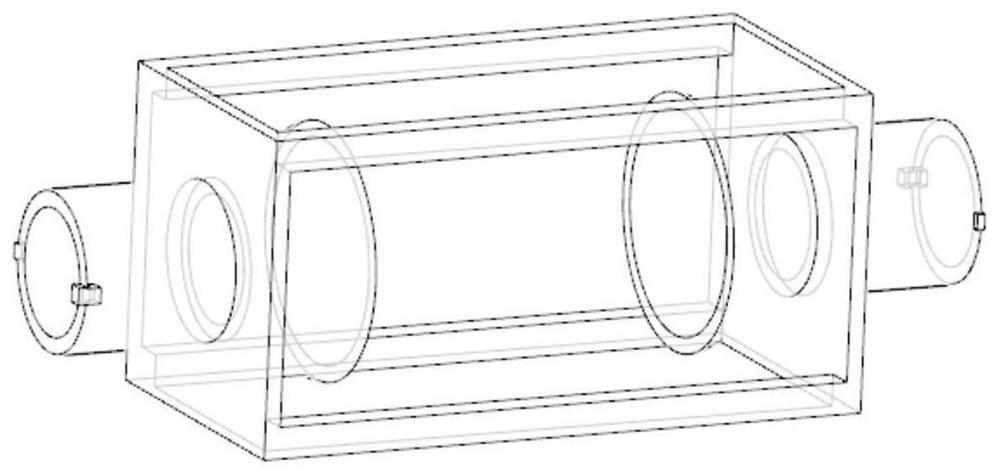

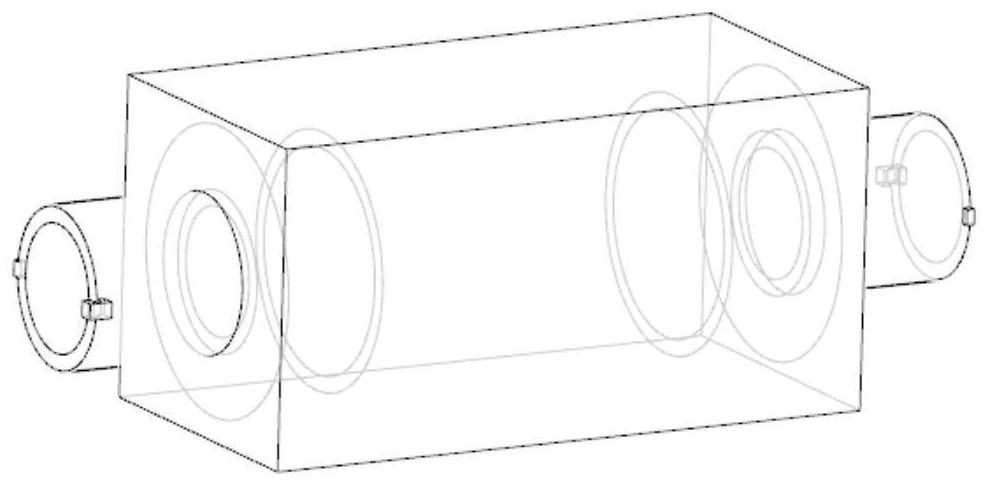

[0040] Shell components (2): including normal temperature shell components (2-1), thermal insulation shell components (2-2) and temperature-adjusting shell components (2-3), which have the function of providing the temp...

example 2

[0051] Example 2: The relationship between formaldehyde absorption rate and formaldehyde concentration

[0052] The reactant carrier assembly (1)(1-1(1)) containing the coating and the normal temperature shell assembly (1)(2-1(1)), the air flow control assembly (1)(4-1(1)), Reaction condition detection component (1)(3-1(1)), conventional component detection component (1)(3-2(1)), air flow control component (2)(4-1(2)), containing formaldehyde absorption Reactant carrier assembly (2)(1-1(2)) and normal temperature housing assembly (2)(2-1(2)), airflow control assembly (3)(4-1(3)), reaction conditions The detection component (2)(3-1(2)), the conventional component detection component (2)(3-2(2)), and the airflow control component (4)(4-1(4)) are sequentially connected in a closed loop and fixed. Fill in the working gas through the gas control assembly. Turn on the control components and detection components, and the gas in the device will reach a steady state after a few seco...

example 3

[0053] Example 3: Relationship between desiccant water absorption and working conditions

[0054] The reactant carrier assembly (3)(1-1(3)) containing water and the normal temperature shell assembly (3)(2-1(3)), the air flow control assembly (5)(4-1(5)), Reaction condition detection component (3)(3-1(3)), conventional component detection component (3)(3-2(3)), air flow control component (6)(4-1(6)), containing desiccant The reactant carrier assembly (4)(1-1(4)) and the temperature regulating shell assembly (1)(2-3(1)), the air flow control assembly (7)(4-1(7)), the reaction conditions The detection component (4)(3-1(4)), the conventional component detection component (4)(3-2(4)), and the air flow control component (8)(4-1(8)) are sequentially connected in a closed loop and fixed. Fill in the working gas through the gas control assembly. Turn on the control components and detection components, and the gas in the device will reach a steady state after a few seconds, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com