Method and device for detecting slag carrying capacity of resistance reducing agent

A detection method and detection device technology, applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., can solve the problem of blind application selection of drag reducer, failure to meet expectations, and no detection of drag reducer slag-carrying ability Methods and devices etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

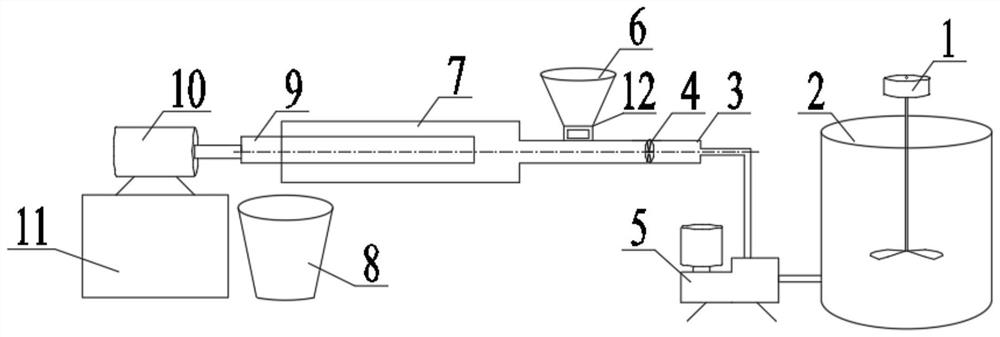

[0042] A method for detecting the slag-carrying ability of a drag reducing agent, comprising the following steps:

[0043] A. Prepare the test solution: mix the drag reducer and water with a mass fraction of the drag reducer of 0.05%, configure the test solution, and inject it into the water tank 2, turn on the mixer 1 to mix the test solution evenly;

[0044] B, configuration slag: by mass percentage: 60 order coal slag 30%, 40 order coal slag 40%, 20 order coal slag 30%, configure the coal slag of 1kg mixed grain size, and put into the slag hopper 6;

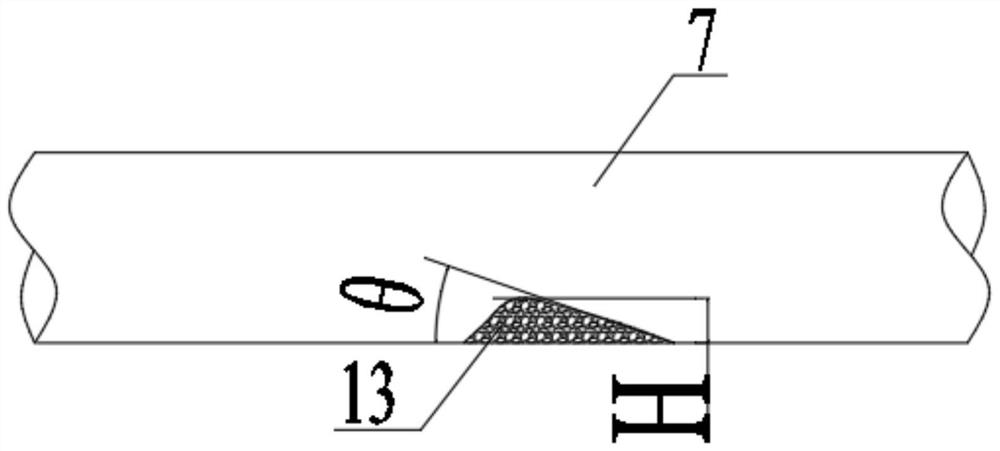

[0045] C. Slag liquid mixing: turn on the flow pump 5, and adjust the flow rate of the flow pump 5 to 50L / min, so that the test liquid enters the mixing tube 3, wherein the inner diameter of the mixing tube 3 is 25mm; at the same time, pull the regulating plate 12 on the slag feeding funnel 6 to make The cinder is lowered into the mixing tube 3 at a speed of 0.1kg / min, and the turbine mixer 4 in the mixing tube 3 makes the tes...

Embodiment 2

[0050] This embodiment includes the following steps:

[0051] A. Prepare the test solution: mix the drag reducer and water with a mass fraction of 0.1% of the drag reducer, prepare the test solution, and pour it into the water tank 2, turn on the mixer 1 to mix the test solution evenly;

[0052] B, configuration slag: by mass percentage: 60 order coal slag 40%, 40 order coal slag 30%, 20 order coal slag 30%, configure the coal slag of 1kg mixed particle size, and put into the slag hopper 6;

[0053] C. Slag liquid mixing: Turn on the flow pump 5, and set the flow rate of the flow pump 5 to 60L / min, so that the test liquid enters the mixing tube 3, wherein the inner diameter of the mixing tube 3 is 25mm; at the same time, pull the regulating plate 12 on the slag feeding funnel 6, The cinder is lowered into the mixing tube 3 at a speed of 0.1kg / min, and the turbine mixer 4 in the mixing tube 3 makes the test liquid flow in a vortex state, so that the test liquid and the cinder a...

Embodiment 3

[0058] This embodiment includes the following steps:

[0059] A. Prepare the test solution: mix the drag reducer and water with a mass fraction of the drag reducer of 0.5%, configure the test solution, and pour it into the water tank 2, and turn on the mixer 1 to mix the test solution evenly;

[0060] B, configuration slag: by coal slag mass percentage: 60 order coal slag 30%, 40 order coal slag 30%, 20 order coal slag 40%, configure the coal slag of 1kg mixed grain size, and put into the slag hopper 6;

[0061] C. Mixing of slag liquid: turn on the flow pump 5, and set the flow rate of the flow pump 5 to 70L / min, so that the test liquid enters the mixing tube 3, wherein the inner diameter of the mixing tube 3 is 25mm; at the same time, pull the regulating plate 12 on the slag feeding funnel 6, The cinder is lowered into the mixing tube 3 at a speed of 0.1kg / min, and the turbine mixer 4 in the mixing tube 3 makes the test liquid flow in a vortex state, so that the test liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com