DCS data mining wet desulphurization system standard emission operation curve acquisition system and method

A wet desulfurization and running curve technology, applied in visual data mining, relational database, database model, etc., can solve the problems of low efficiency and high cost, and achieve the effect of ensuring the discharge up to the standard and solving the high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0051] The present invention provides a DCS data mining method for obtaining the operation curve of the wet desulfurization system's up-to-standard discharge, which can obtain the operation curve of the desulfurization equipment in line with the actual working conditions, which can be used as a reference for the operators to adjust the operation parameters reasonably to ensure that the SO 2 Pollutant discharge up to standard.

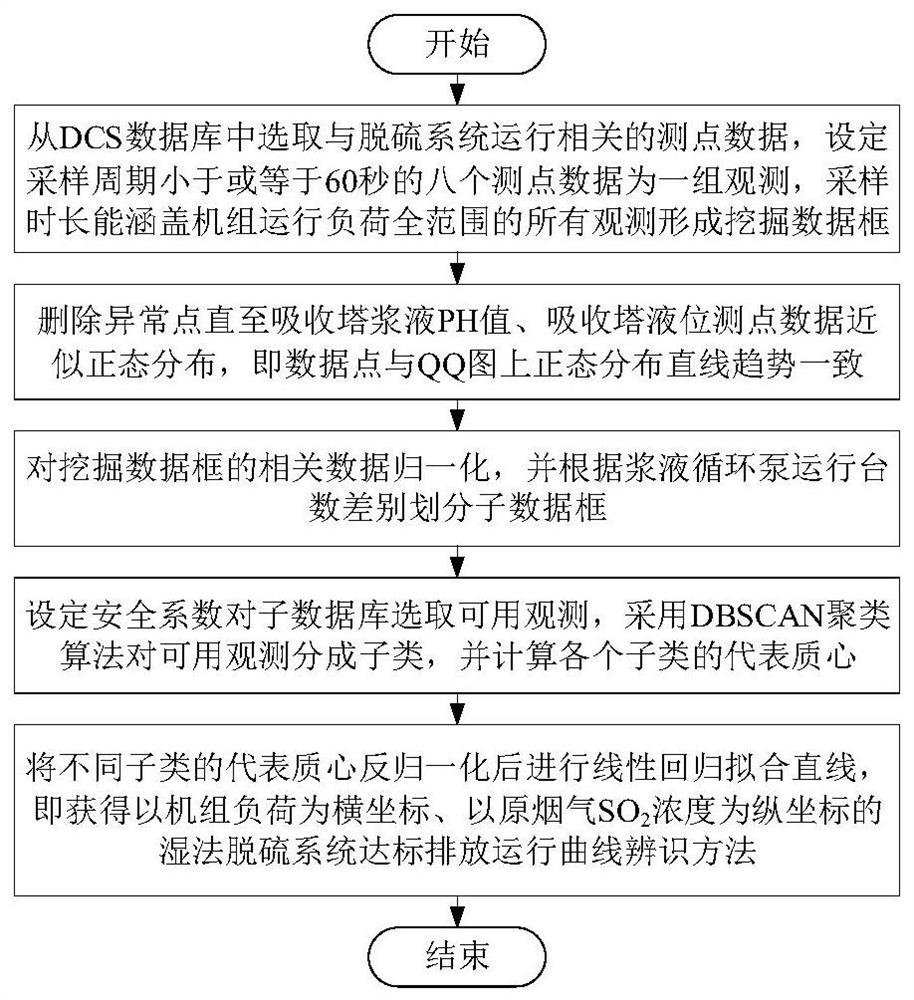

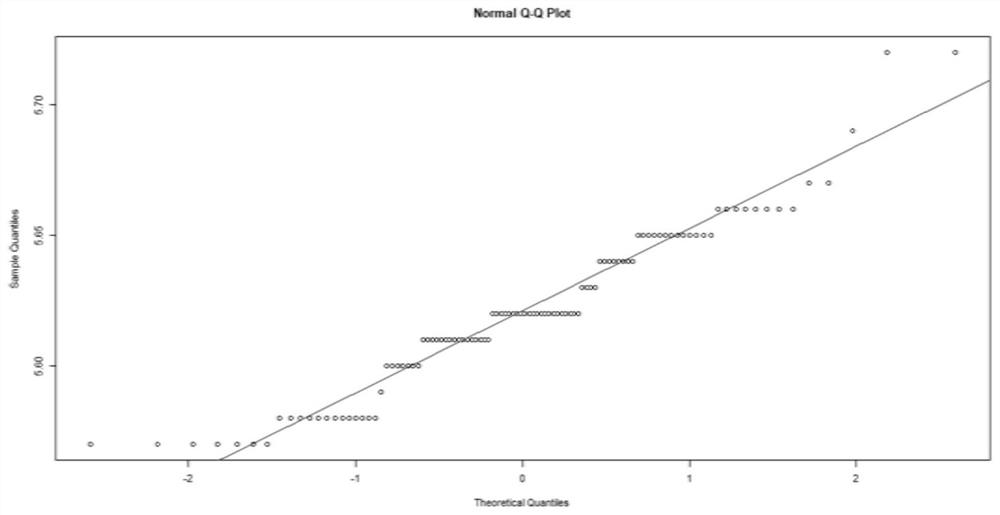

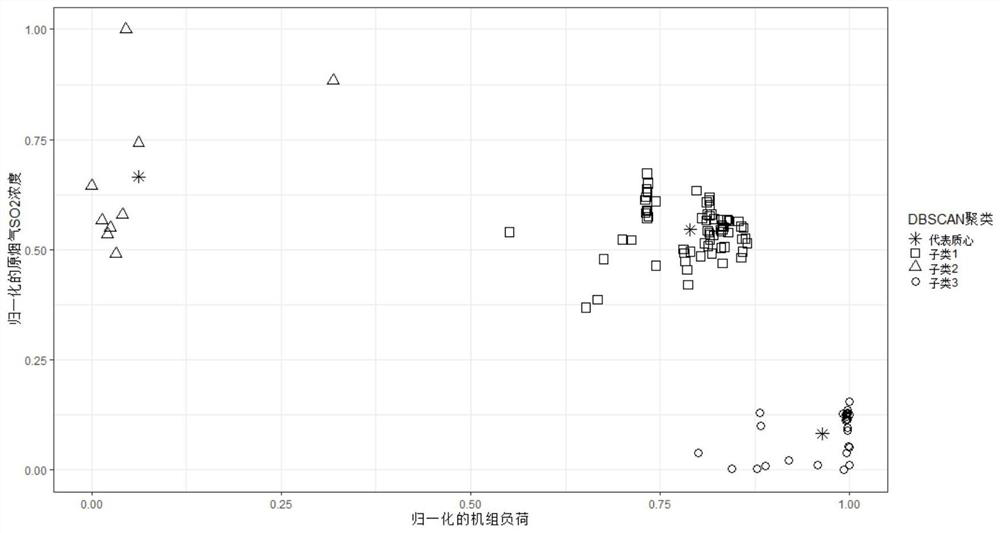

[0052] Such as Figure 1 to Figure 4 As shown, the method for obtaining the up-to-standard discharge operation curve of a DCS data mining wet desulfurization system provided by the present invention comprises the following steps:

[0053] Step 1: Take the coal-fired unit’s rated load from 50% to 100% of the rated load as the sampling range, and obtain the mining data frame from the DCS database of the coal-fired unit with a preset sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com