Positive-pressure airflow forced seed conveying and guiding pipe

A technology of seed guide tube and air flow, which is applied in the direction of sowing, sowing seeder, planter parts, etc., which can solve the problem of friction and collision between seeds and the inner wall of the seed guide tube, which will affect the operation efficiency, sowing qualification rate and consistent plant distance Improve the efficiency of planting operation and improve the quality of operation, etc., and achieve the effect of simple and convenient regulation, high efficiency of seeding operation, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

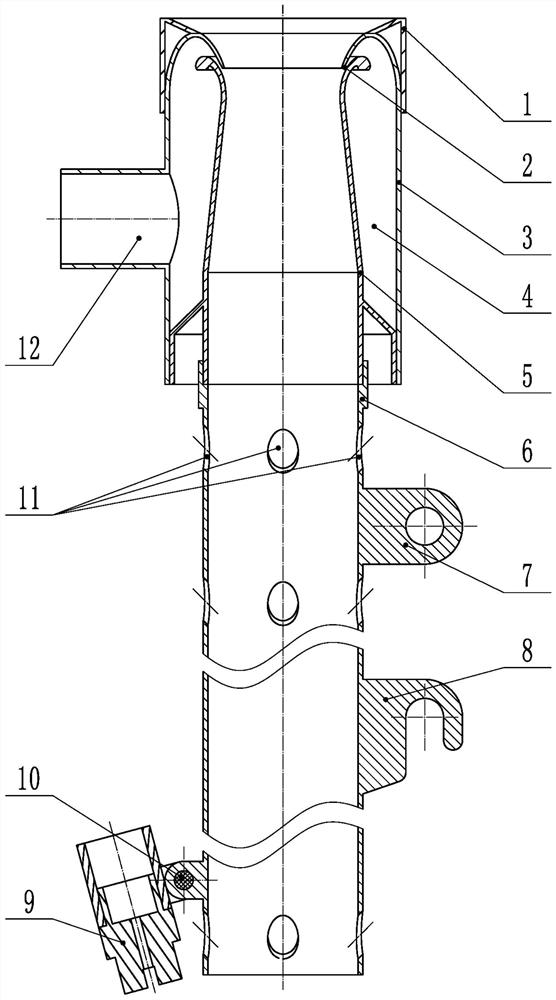

[0009]The present invention has been described in detail below with reference to the accompanying drawings. A positive pressure gas stream is forced to specify the catheter tube, and in the outer portion of the cylindrical inner casing 5, the outer side of the cylindrical inner casing 5 is provided with the inner side of the cylinder housing 3. The annular gas chamber 4 is provided with an annular airway 2 at a portion between the upper end of the cylindrical inner casing 5 and the upper end of the cylindrical casing 3, the annular gas chamber 4 through the annular valve 2 and a cylindrical inner casing 5 The inner cavity is connected, and the lower end of the annular gas chamber 4 is sealed; the pressure gas inlet 12 with the ring air chamber 4 is opened on the side wall of the cylinder outer casing 3, and the funnel-shaped inoculation cover 1 is fastened in the cylinder housing 3. On the upper end; the mounting tube 6 is sealed on the lower portion of the cylindrical inner casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com