Preparation method of novel sauce stewed chicken meat

A chicken and sauce brine technology, which is applied in gas-containing food ingredients, food ultrasonic treatment, food processing, etc., can solve the problems of restricting the efficiency of brine making, long time of braising, and incomplete utilization of key aroma components, etc., so as to improve the extraction rate, The effect of improving the taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

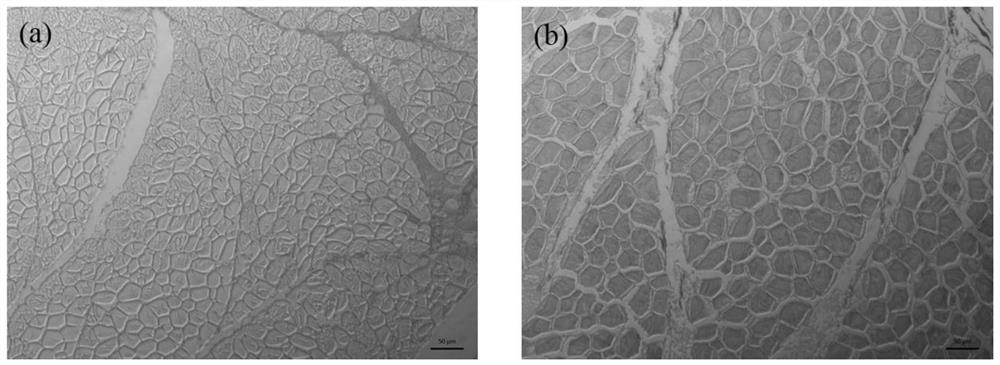

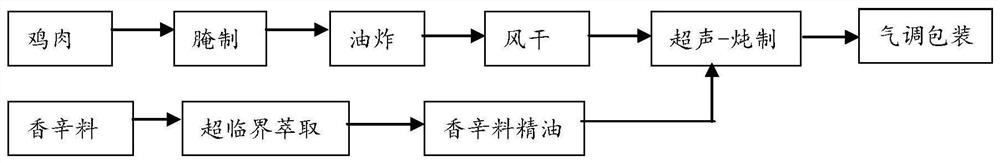

[0022] refer to figure 1 and figure 2 A kind of preparation method of novel sauce marinated chicken comprises the following steps:

[0023] (1) Selection of raw materials: choose fresh live chickens, slaughtered, eviscerated, cleaned and matured chickens (the weight of the chickens should be 1kg) or frozen chickens as raw materials.

[0024] (2) Marinating: Prepare the marinating liquid, configure according to the ratio of water: baking soda: salt: trehalose = 100:0.5:1:0.5, put the cleaned chicken into the marinating liquid, and marinate at a temperature of 5-10 ℃, pickling time 12h.

[0025] (3) Frying: Drain the marinated chicken, and evenly coat it with sugar water. The ratio of sugar water is honey: water = 1:3. The frying temperature is 170-190°C, and fry for 1-2min.

[0026] (4) Air-drying: the fried chicken is dried at 30-40° C. for 10 hours, and the yield is controlled at 67%.

[0027] (5) Braised:

[0028] a. Extracting essential oils of spices: Grind star ani...

Embodiment 2

[0034] A kind of preparation method of novel sauce marinated chicken comprises the following steps:

[0035] (1) Selection of raw materials: choose fresh live chickens, slaughtered, eviscerated, cleaned and matured chickens (the weight of the chickens should be 1kg) or frozen chickens as raw materials.

[0036] (2) Marinating: Prepare the marinating liquid, configure according to the ratio of water: baking soda: salt: trehalose = 100:1:1:0.5, put the cleaned chicken into the marinating liquid, and marinate at a temperature of 5-10 ℃, pickling time 24h.

[0037] (3) Frying: Drain the marinated chicken, and evenly coat it with sugar water. The ratio of sugar water is honey: water = 1:3. The frying temperature is 170-190°C, and fry for 1-2min.

[0038] (4) Air-drying: the fried chicken is dried at 30-40° C. for 12 hours, and the yield is controlled at 65%.

[0039] (5) Braised:

[0040] a. Extracting essential oils of spices: Grind star anise, Chinese prickly ash, angelica da...

Embodiment 3

[0046] A kind of preparation method of novel sauce marinated chicken comprises the following steps:

[0047] (1) Selection of raw materials: choose fresh live chickens, butchered, eviscerated, washed and matured chickens (the weight of bare chickens is preferably 1kg) or frozen chickens as raw materials.

[0048] (2) Marinating: Prepare the marinating liquid, configure according to the ratio of water: baking soda: salt: trehalose = 100:1:1:1, put the cleaned chicken into the marinating liquid, and marinate at a temperature of 5-10 ℃, pickling time 20h.

[0049] (3) Frying: Drain the marinated chicken, and evenly coat it with sugar water. The ratio of sugar water is honey: water = 1:3. The frying temperature is 180°C, and fry for 1-2 minutes.

[0050] (4) Air-drying: Dry the fried chicken at 30-40° C. for 8 hours, and the yield is controlled at 70%.

[0051] (5) Braised:

[0052] a. Extracting essential oils of spices: Grind star anise, Chinese prickly ash, angelica dahuric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com