Device for automatically preparing electrolyte and using method thereof

An automatic configuration, electrolyte technology, applied in the direction of driving stirrer dissolution, chemical instruments and methods, mixers with rotary stirring devices, etc. It can reduce the frequency of manual feeding and error rate, improve the consistency of product quality, and solve the effect of electrolyte concentration fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

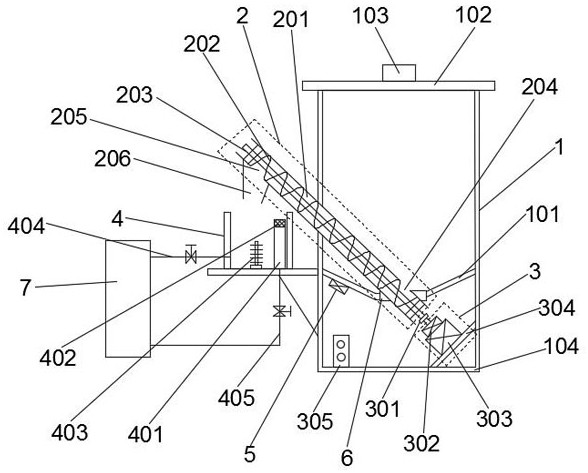

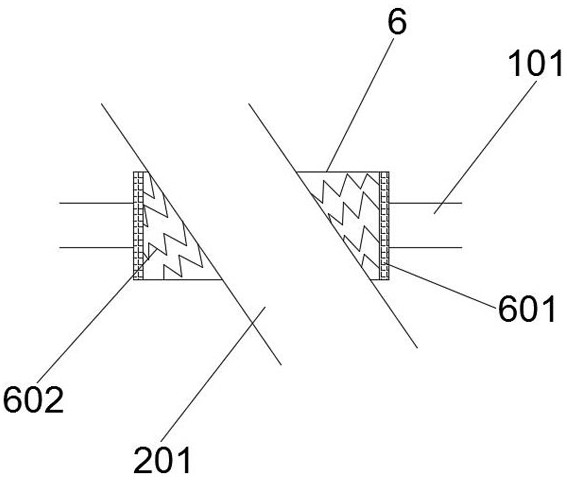

[0029] Such as Figure 1-2As shown, a device for automatically configuring electrolyte includes a storage tank 1, a material guide pipe fitting 2, a speed change system 3, a dissolution tank 4, a vibration motor 5, an electrolytic tank 7 and a control system; the inside of the storage tank 1 A funnel-shaped interlayer board 101 is provided; the funnel-shaped interlayer board 101 divides the storage tank 1 into upper / lower layers; the speed change system 3 includes a reduction box 302, a speed-regulating motor 303, and a speed-regulating controller 305 and support plate 304; the support plate 304 is obliquely arranged on the lower floor of the storage tank 1; the speed regulating motor 303 is arranged on the support plate 304; the reduction box 302 is connected with the speed regulating motor 303; the speed regulating control The device 305 is arranged on the outer wall of the storage tank 1; the guide tube 2 includes a guide tube 201, a lifting screw 202 and a rotating shaft 2...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that: the overflow pipe 401 is vertically arranged on the bottom of the dissolution tank 4 , and a filter screen 402 is arranged at the top opening.

[0041] The usage method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 2 is that: the outlet 205 is connected with an outlet conduit 206 with an opening facing downward.

[0044] The usage method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com