Environment-friendly mechanical device for solid waste smashing

A solid waste and mechanical device technology, applied in the direction of drying gas arrangement, dryer, press, etc., can solve the problems of inability to crush waste, poor crushing effect, unfavorable treatment, etc., achieve improved crushing effect, easy storage, Improve the effect of filtering and screening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

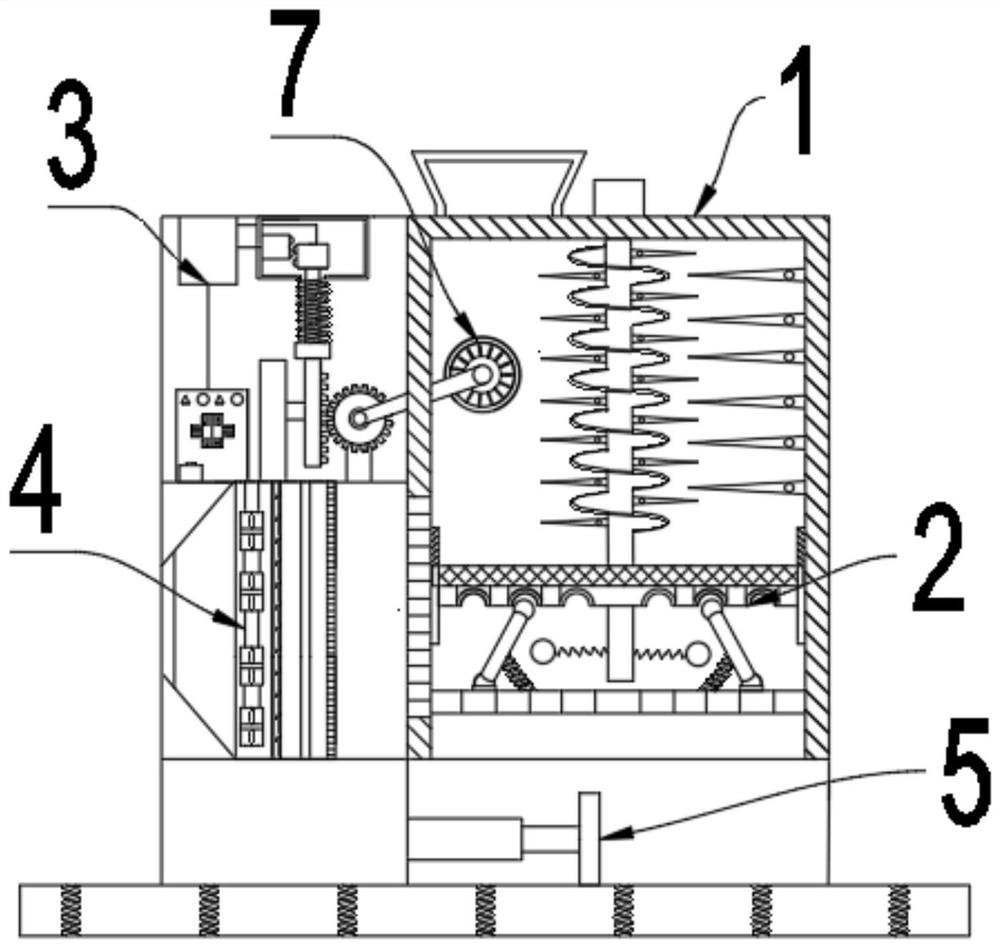

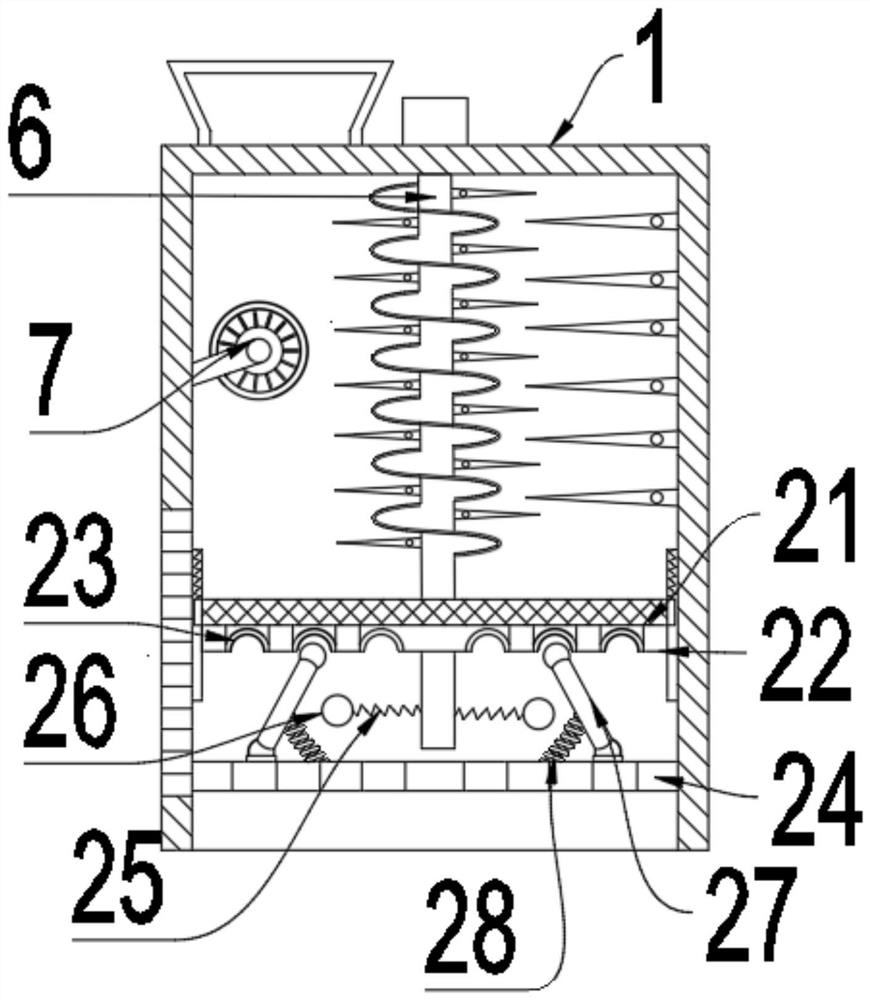

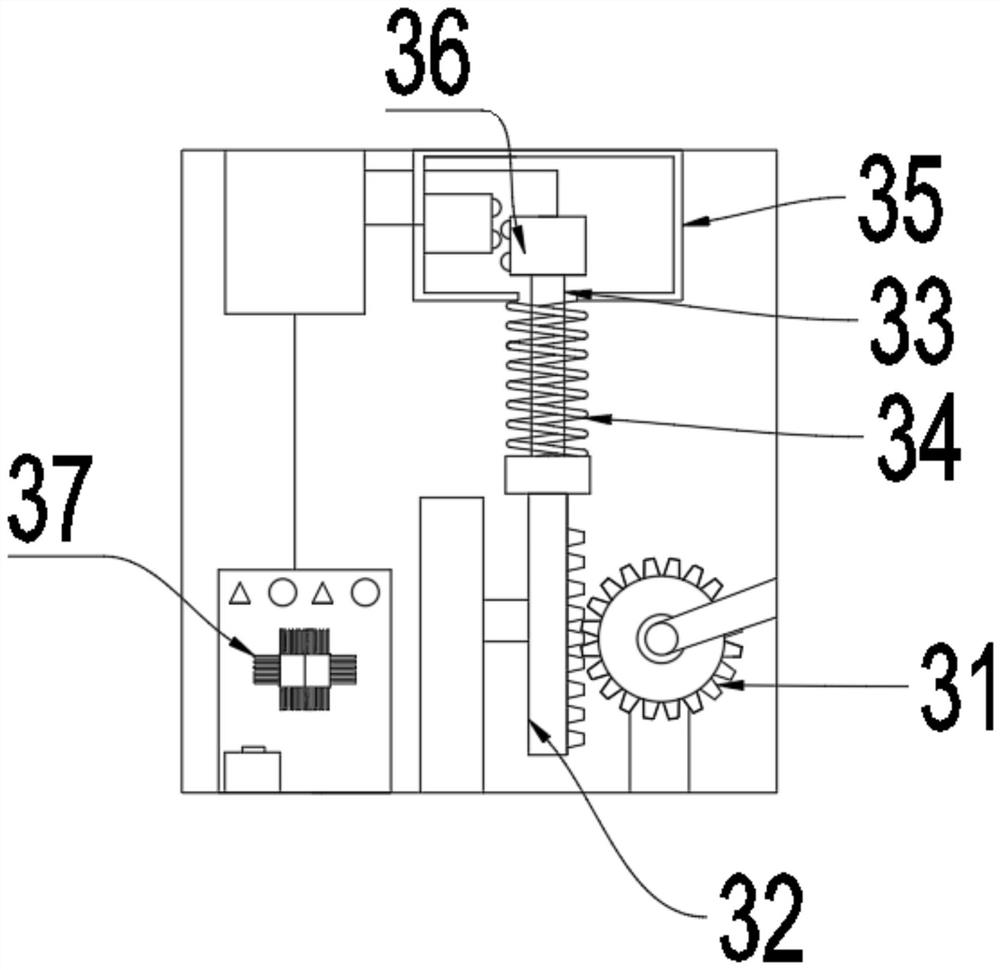

[0028] refer to Figure 1 ~ Figure 4, an environmentally friendly mechanical device for crushing solid waste, including a bottom plate and a crushing box 1 fixedly installed above the bottom plate, a motor is fixedly installed on the upper surface of the crushing box 1, and a crushing shaft 6 is connected to the output end of the motor. Both sides of the shaft 6 are symmetrically equipped with a plurality of crushing projections, and a filter device 2 is arranged below the crushing shaft 6. The filter device 2 includes a filter plate 21 slidingly installed on the inner wall of the crushing box 1, and the filter plate 21 is sleeved on the On the side of the crushing shaft 6, the lower bottom surface of the filter plate 21 is fixedly equipped with a blanking plate 22, and the lower bottom surface of the blanking plate 22 is provided with a plurality of arc-shaped grooves 23, and the upper and lower surfaces of the blanking plate 22 are provided with a plurality of through holes. ...

Embodiment 2

[0036] refer to Figure 5 , an environmentally friendly mechanical device for crushing solid waste. Compared with Embodiment 1, the drying device 4 in this embodiment includes an air guide box 41 fixedly installed on the side of the crushing box 1, and the inside of the air guide box 41 is fixedly installed with Fan 42 , dust removal net 43 and heating wire 44 , and a plurality of air outlets 45 are provided on the side of the air guiding box 41 .

[0037] Working principle: when in use, it is convenient to dry the waste by setting the drying device 4, it is convenient to introduce clean air into the device by setting the fan 42 and the dust removal net 43, and it is convenient to heat the air by setting the heating wire 44.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com