Hot ventilation reinforced petroleum hydrocarbon contaminated soil in-situ remediation method

An in-situ remediation and contaminated soil technology, applied in the restoration of contaminated soil, etc., can solve the problems of technical research and engineering implementation gaps, etc., and achieve the effects of increasing desorption efficiency, increasing growth, and small site disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

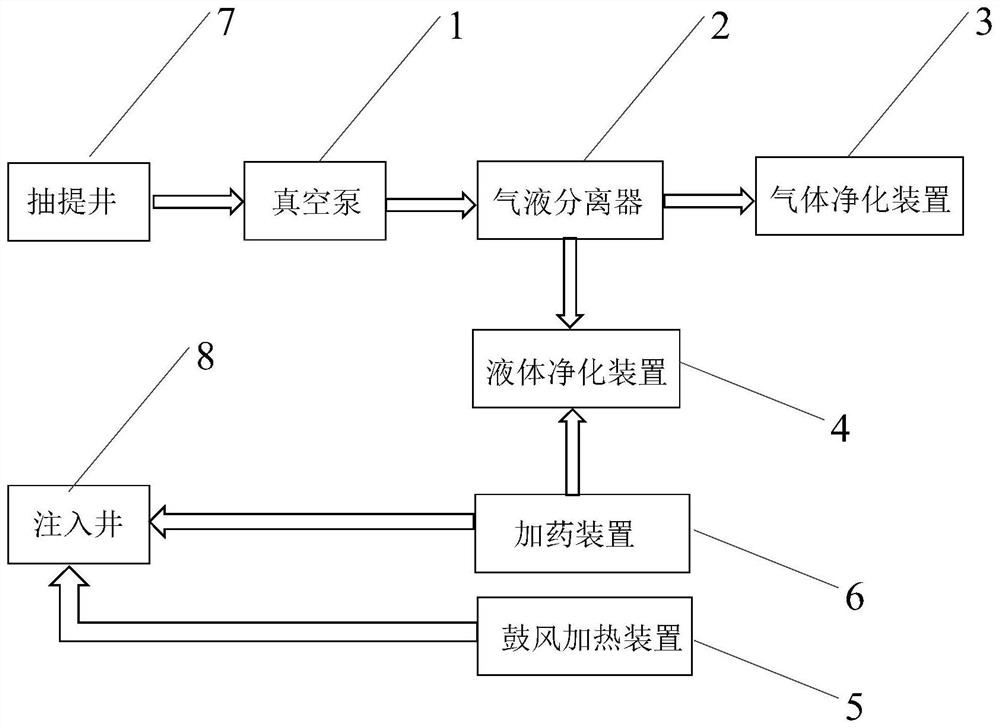

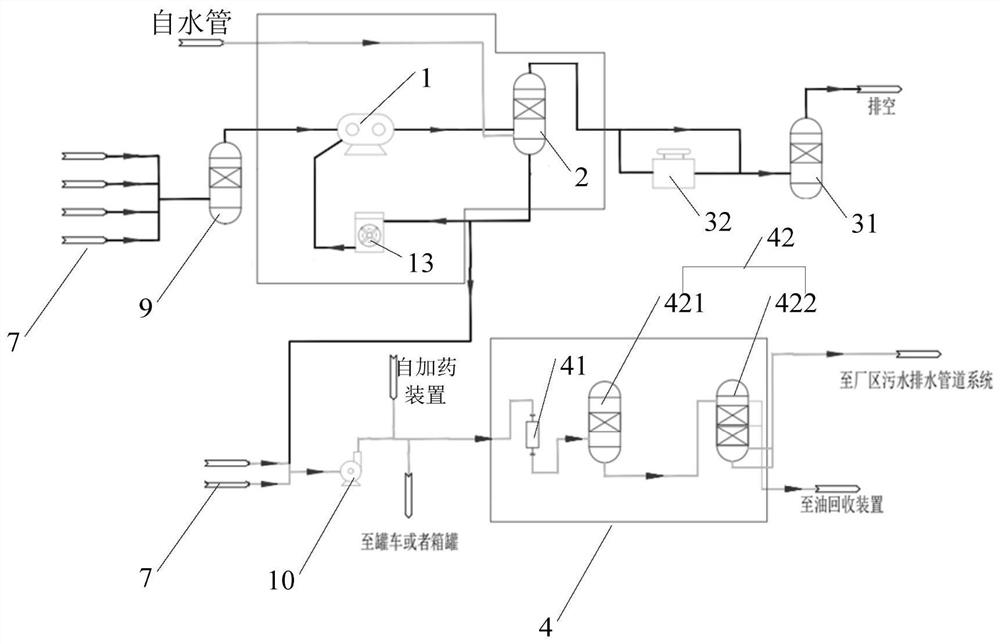

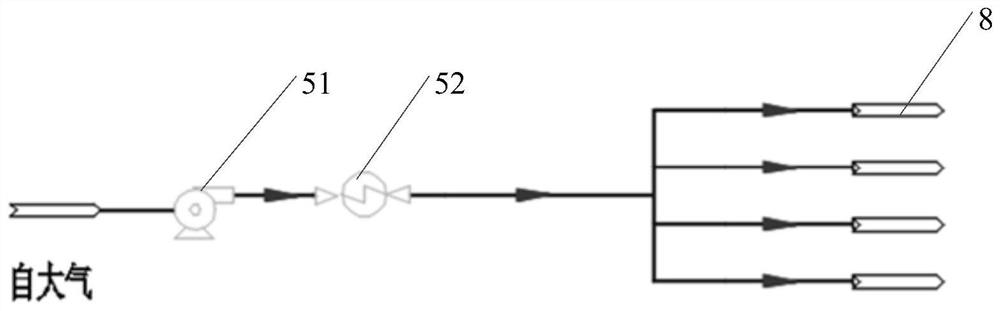

[0065] This embodiment provides a kind of in-situ remediation device for thermally ventilated and strengthened petroleum hydrocarbon contaminated soil, such as Figure 1 ~ Figure 4 as shown,

[0066] include:

[0067] Vacuum extraction system, used to extract groundwater and soil gas in remediation wells, and remove volatile organic compounds; and blower injection skid, used to blow air into remediation wells and inject soil remediation agents to remove volatile and semi-volatile organic compounds ;

[0068] Such as figure 2 , the vacuum extraction system includes:

[0069] Vacuum pump 1 is connected with extraction well 7 for extracting groundwater and soil gas;

[0070] The gas-liquid separator 2, whose fluid inlet is connected to the vacuum pump, is used to separate the groundwater and soil gas extracted by the vacuum pump into gas-liquid;

[0071] Gas purification device 3 is used to remove the volatile organic compounds contained in the gas separated by the gas-liqu...

Embodiment 2

[0078] This embodiment provides a method for in-situ remediation of petroleum hydrocarbon-contaminated soil with heat-ventilated enhancement. The method uses the in-situ remediation device for heat-ventilated enhanced petroleum hydrocarbon-contaminated soil described in Example 1, including the following steps:

[0079] 1) On-site test is carried out in the storage tank landfill area, the site area is about 200m 2 (Length×Width, 20m×10m), samples were collected between each tank, a total of 6 point soil samples were collected, and the depth of samples collected at each point was 0 m, 0.5 m, 1.0 m, 1.5 m, 3.0 m m, 6.0 m, such as Figure 5 shown;

[0080] The direct push soil sampling equipment geoprobe was used to collect soil samples on site, and MIP (membrane interface probe) monitoring was carried out while drilling, and the pollutants were determined to be gasoline and diesel, and the pollutant concentration range was 1000-3500mg / kg; according to the on-site soil sample co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com