Self-sinking and floating adsorption balloon for wastewater floating oil treatment

A technology for adsorption balls and oil slicks, which is applied in the direction of adsorption of water/sewage treatment, grease/oily substance/floating matter removal devices, liquid separation, etc. It can solve the problem of poor adsorption effect, limited contact area between adsorption cotton and oil slick Timely replacement of absorbent cotton and other issues to achieve the effect of improving the adsorption effect, increasing the oil absorption rate, and expanding the adsorption surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

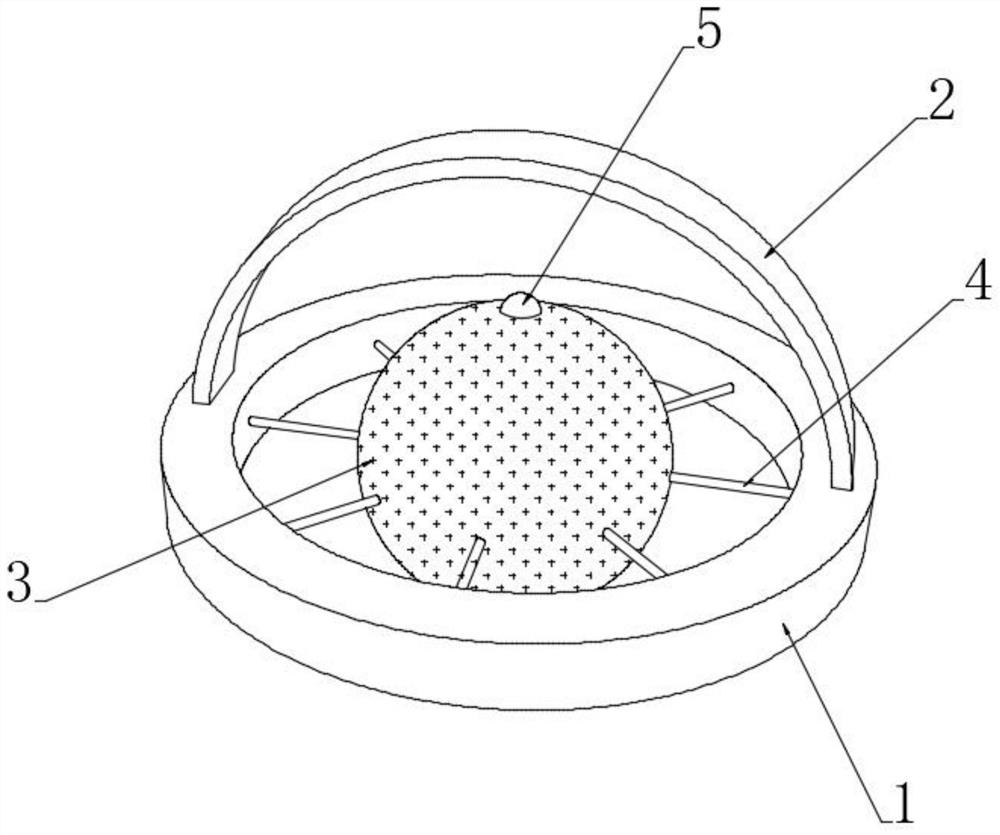

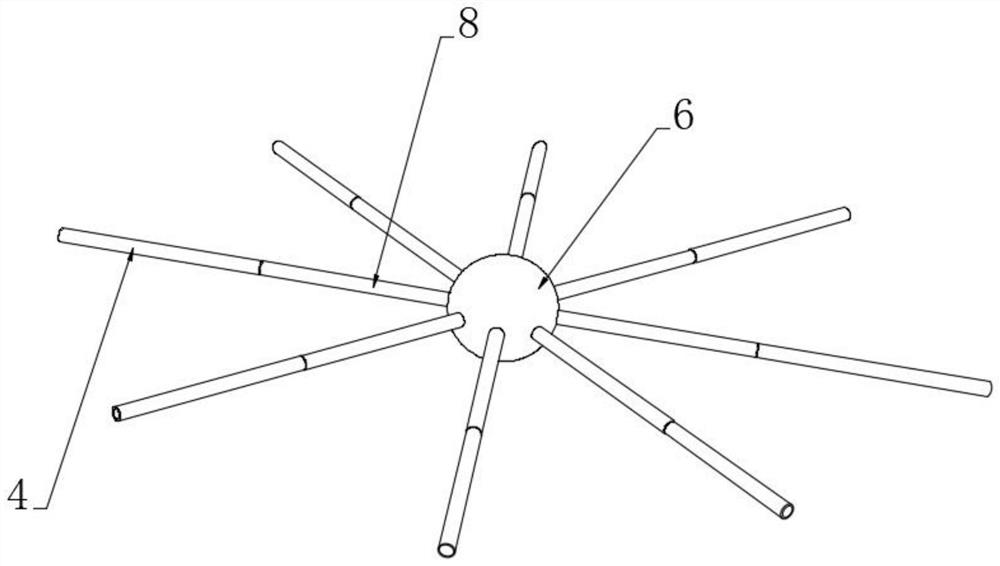

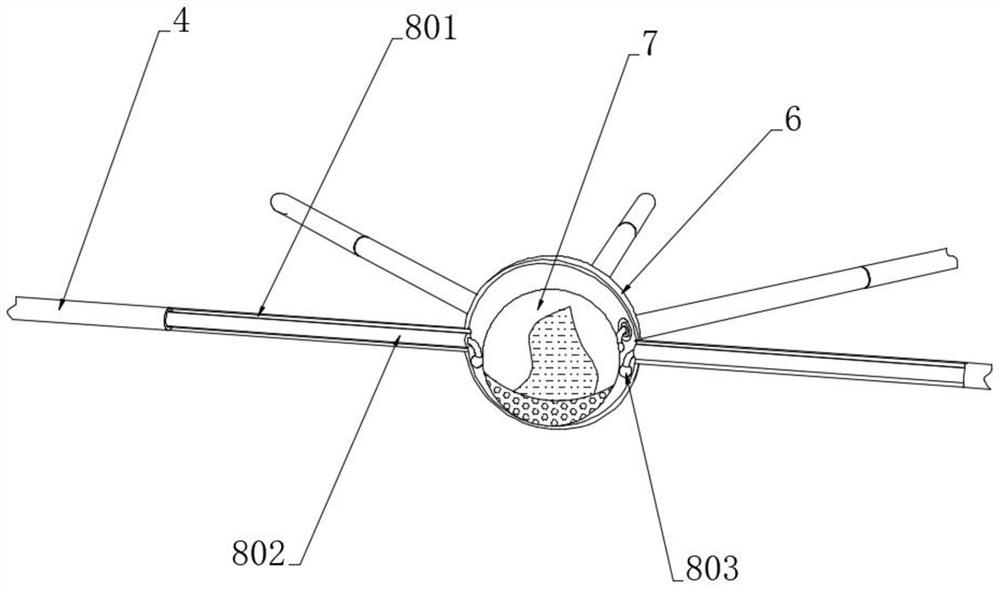

[0042] see figure 1 and Figure 6 , a self-sinking and floating adsorption balloon for wastewater oil slick treatment, comprising an annular floating plate 1, a plurality of outer suspension rods 4 are annularly distributed on the inner side wall of the annular floating plate 1, and the inner ends of the plurality of outer suspension rods 4 are connected There is an adsorption ball 3, the adsorption ball 3 is located at the lower end of the arc suspension plate 2, the adsorption ball 3 includes an inner adsorption filler 301 located on the inner side, the outer end of the inner adsorption filler 301 is covered with an outer oil-absorbent cotton 302, and the inner adsorption filler 301 is Spherical embedding skeleton made of ceramic materials, the pores of the spherical embedding skeleton are filled with modified fiber balls, and the inner adsorption filler 301 is made of oil-absorbing and non-water-absorbing materials. The inner adsorption filler 301 effectively blocks water m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com