PVC sheet heat-resistant modifier ACR

A technology of heat-resistant modifiers and sheets, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, chemical/physical processes, etc., can solve the problem of poor heat resistance of modifier ACR, reaction There are safety hazards and other problems in the equipment, and the effect of improving the resistance to 80 degrees Celsius is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

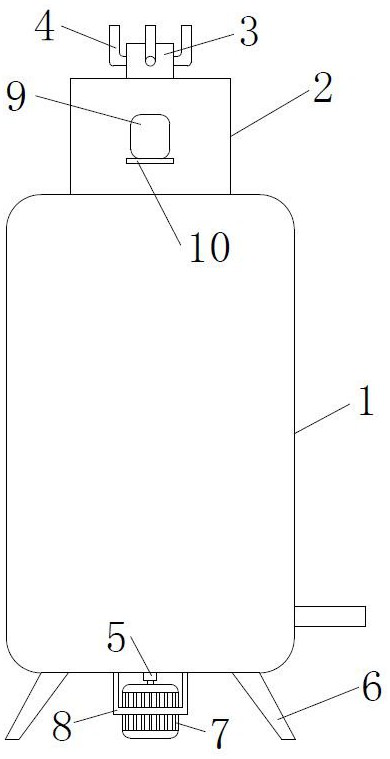

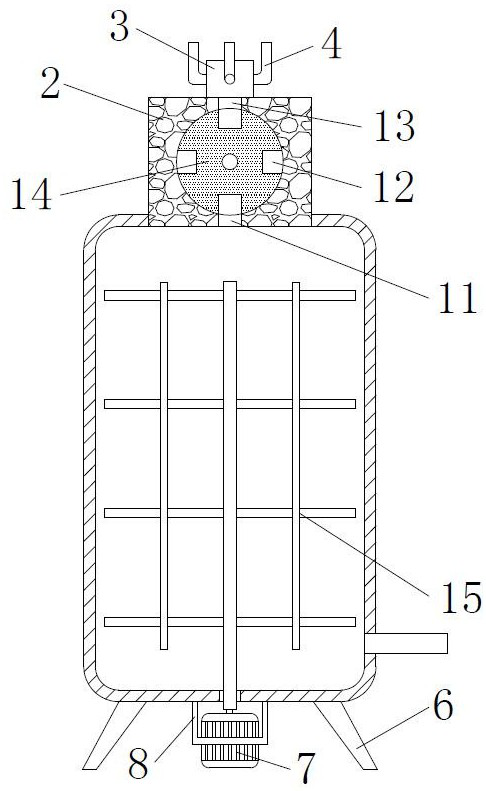

[0026] Such as Figure 1-3 As shown, the embodiment of the present invention provides a PVC sheet heat-resistant modifier ACR, including the following materials, according to the following formula to weigh each part by weight of raw materials: 35 parts of styrene, 47 parts of acrylonitrile, 40 parts of methacrylates , 20 parts of α-methylstyrene, 30 parts of glycidyl methacrylate, PVC sheets are obtained by copolymerizing styrene, acrylonitrile, methacrylates, α-methylstyrene and glycidyl methacrylate Material heat-resistant modifier ACR, styrene, acrylonitrile, methacrylates, α-methylstyrene and glycidyl methacrylate copolymerization reaction equipment is anti-leakage reaction equipment.

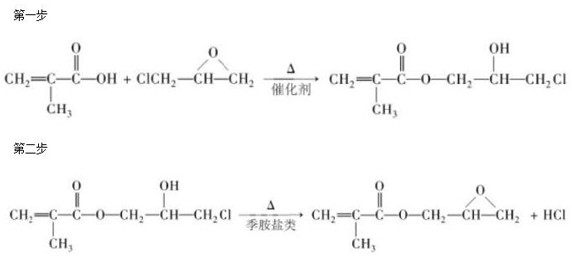

[0027] The copolymerization pressure of styrene, acrylonitrile, methacrylates, α-methylstyrene and glycidyl methacrylate is normal pressure, and the copolymerization temperature is 75 degrees Celsius. Glycidyl methacrylate is synthesized by a phase transfer method. The synthesis method is ...

Embodiment 2

[0031] Glycidyl methacrylate is synthesized by an esterification ring-closing method. First, methacrylic acid and epichlorohydrin are subjected to a ring-opening esterification reaction to generate methacrylate-2-hydroxyl-3-chloropropyl. Then dehydrochlorination ring-closing reaction of methacrylic acid-2-hydroxyl-3-chloropropyl in the presence of sodium hydroxide solid or aqueous solution, or reflux in acetone solution of potassium carbonate to obtain the product.

Embodiment 3

[0033] The raw materials were weighed according to the following formula: 37 parts of styrene, 49 parts of acrylonitrile, 42 parts of methacrylates, 25 parts of α-methylstyrene, and 33 parts of glycidyl methacrylate.

[0034] The copolymerization pressure of styrene, acrylonitrile, methacrylates, α-methylstyrene and glycidyl methacrylate is normal pressure, and the copolymerization temperature is 77 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com