Self-repairing emulsion with core-shell structure as well as preparation method and application thereof

A core-shell structure, self-healing technology, applied in the direction of coating, etc., can solve the problems of high price, difficult industrialization of multiple hydrogen bond monomers, and low cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

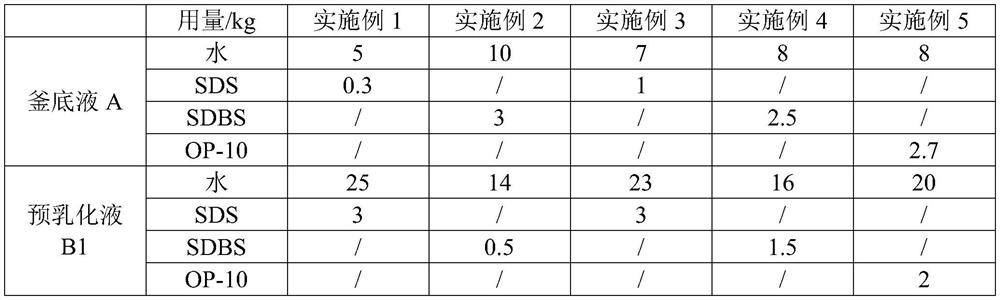

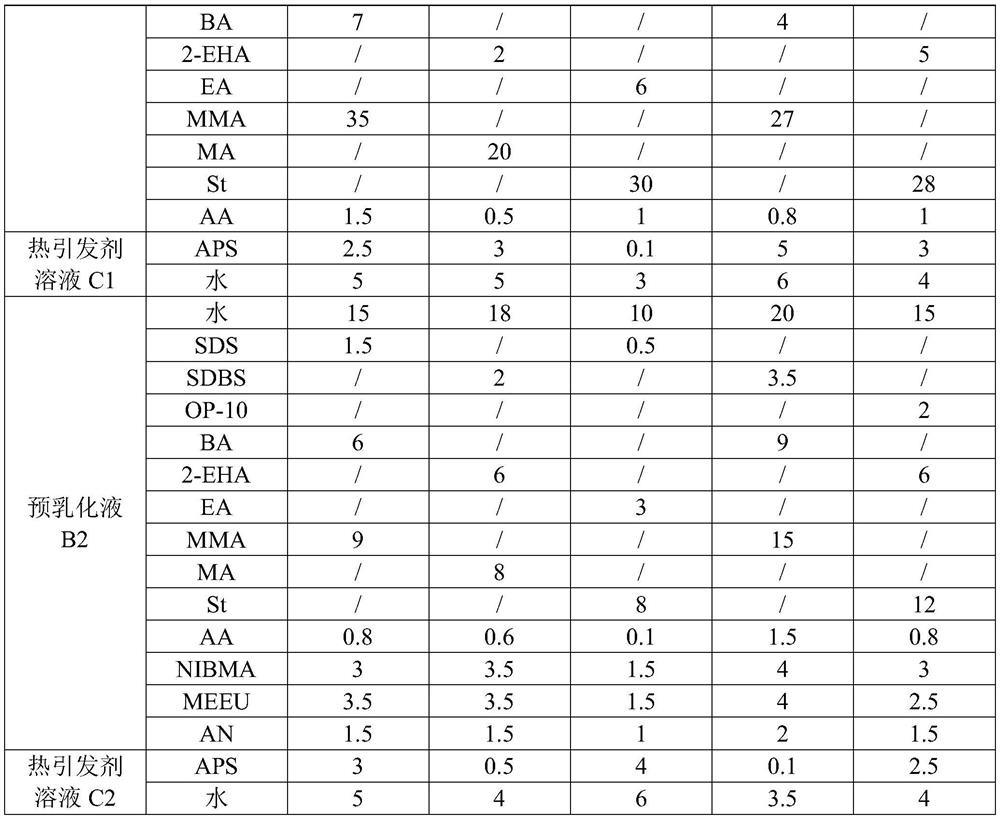

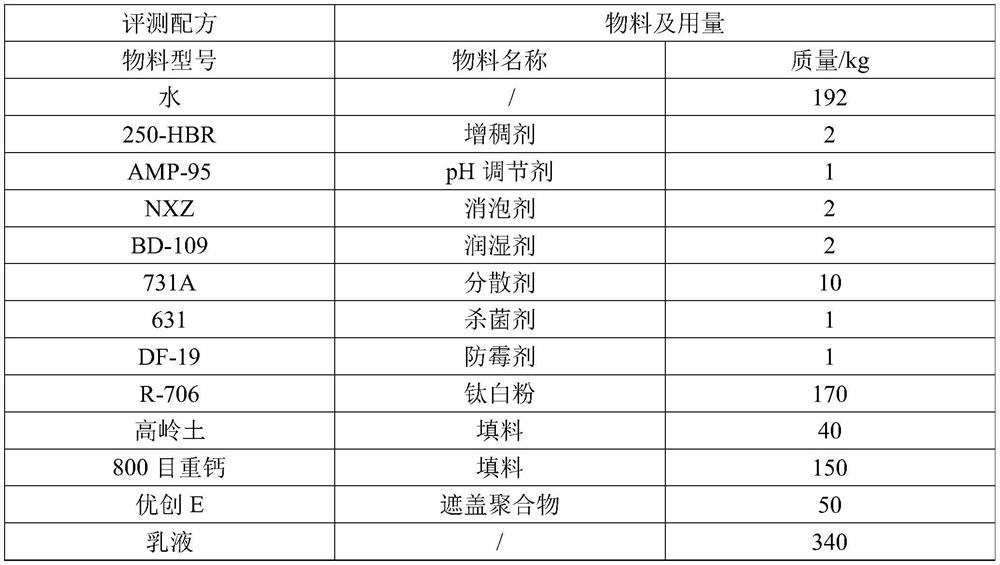

[0062] Prepare the self-healing emulsion with core-shell structure according to the composition and consumption of raw materials in Table 1 and the following steps:

[0063] a. Add still bottom liquid A to the polymerization kettle with stirring device, condenser and peristaltic pump feeding device;

[0064] b. Add pre-emulsion B1 to the first pre-emulsification tank, stir and mix evenly for later use;

[0065] c. Add thermal initiator solution C1 to thermal initiator tank one;

[0066] d. Add pre-emulsion B2 to the second pre-emulsion, stir and mix evenly for later use;

[0067] E, add thermal initiator solution C2 in thermal initiator tank two;

[0068] f. When the temperature in the polymerization tank reaches 80°C, add 10% of the pre-emulsion B1 and 10% of the thermal initiator solution C1 into the tank, and then add the remaining pre-emulsion B1 and thermal initiator dropwise to the polymerization tank at the same time. Initiator solution C1; when pre-emulsion B1 and C1 ...

Embodiment 2-5

[0074] The self-healing emulsion was prepared according to the raw material composition in Table 1, and other operating conditions and methods were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com