Concrete pavement joint cutter

A technology for concrete pavement and slitting machine, which is applied in the field of slitting machine and concrete pavement slitting machine, can solve the problems of increasing the resistance of blade rotation and aggravating blade wear, and achieves the advantages of intensifying wear, prolonging length and maintaining sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

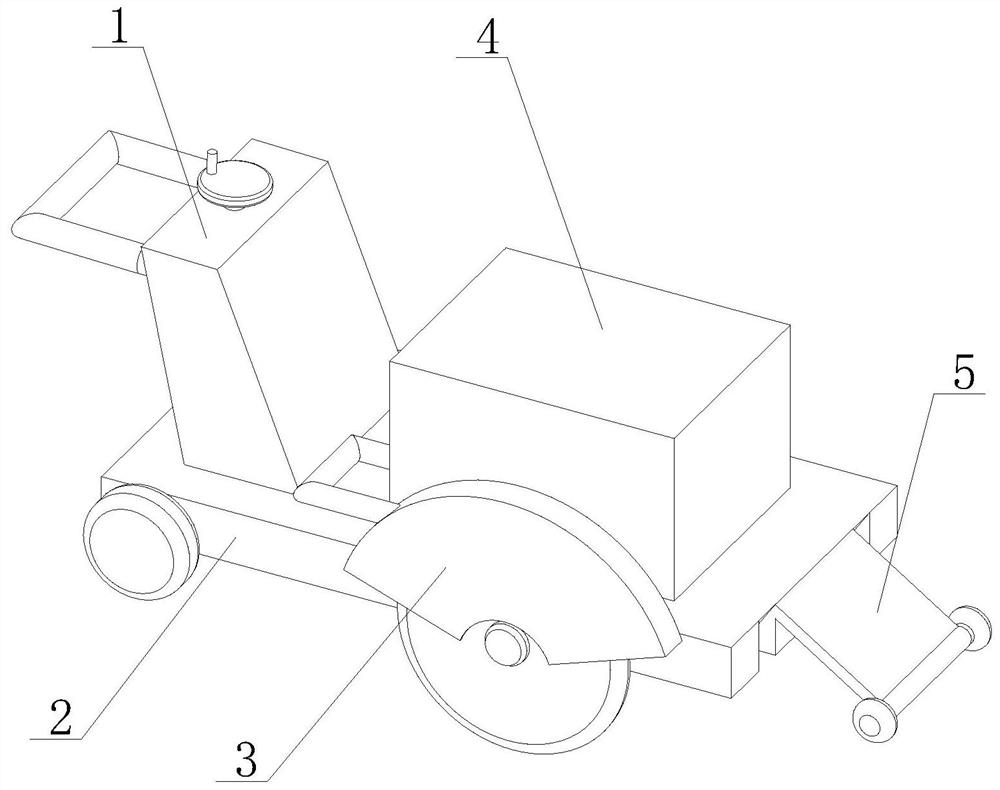

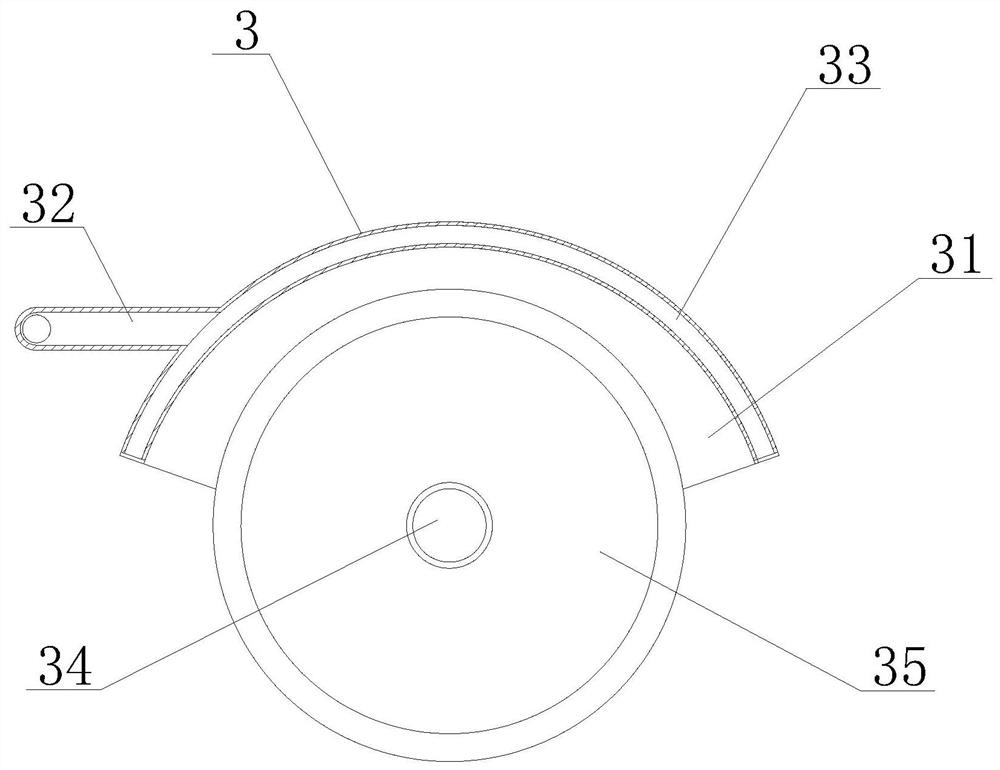

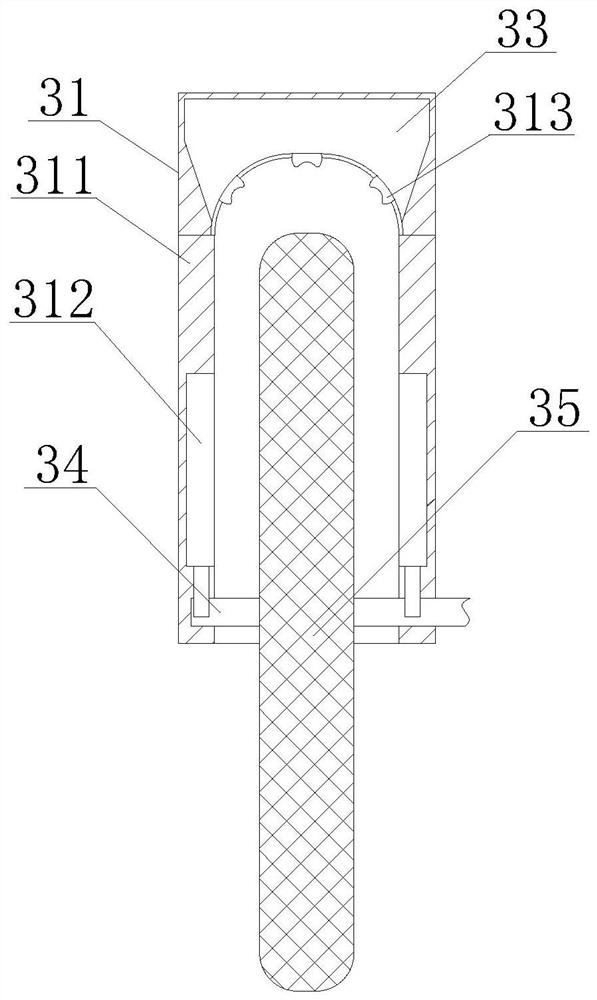

[0029] Such as Figure 1-Figure 6 As shown, the invention provides a concrete pavement cutting machine, comprising a control mechanism 1, the bottom surface of the control mechanism 1 is fixedly connected with a base mechanism 2, one side of the control mechanism 1 is provided with a power mechanism 4, and the bottom surface of the power mechanism 4 is connected to the The top of the base mechanism 2 is fixedly connected, the side of the base mechanism 2 away from the control mechanism 1 is fixedly installed with a guide wheel mechanism 5, the front of the power mechanism 4 is provided with a cutting mechanism 3, and the cutting mechanism 3 is fixedly installed on the outer wall of the base mechanism 2. The transmission connection between the mechanism 3 and the power mechanism 4, the cutting mechanism 3 includes a protective device 31, the top of the protective device 31 is provided with a water channel 33, one side of the protective device 31 is fixedly connected with a commu...

Embodiment 2

[0031] Such as Figure 6-8As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the interior of the water inlet 1313 is provided with a communication device 131, the outer wall of the communication device 131 is fixedly connected with the inner wall of the water inlet 1313, and the lower part of the communication device 131 is provided There is a water storage cavity 132, and the interior of the water storage cavity 132 is provided with a fixed block 133, the outer wall of the fixed block 133 is fixedly connected with the inner wall of the water inlet 1313, and a movable plate 134 is arranged under the water storage cavity 132, and the two ends of the movable plate 134 are fixed Connected with the contact block 135, by adopting the combination of the fixed block 133, the movable plate 134, and the contact block 135, it can be realized that when the cutting piece 35 rotates at a high speed, a high-speed airflow will pass under the water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com