Automatic extrusion structure

A technology of automatic extrusion and turntable mechanism, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. It can solve problems that affect normal use, inaccurate test results, and uncontrollable air pressure, etc., to achieve The effect of simple structure, high accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

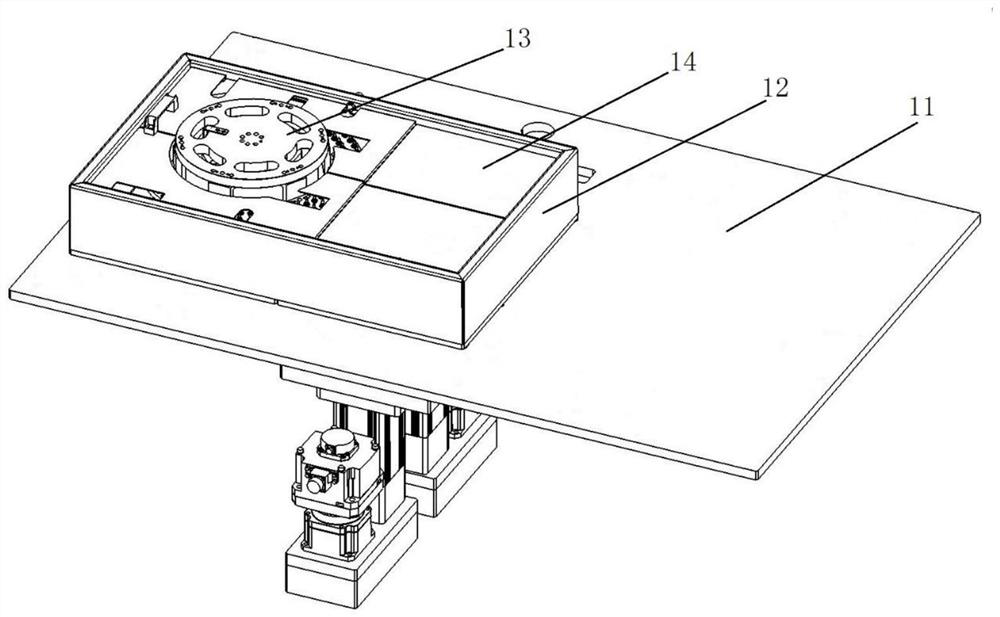

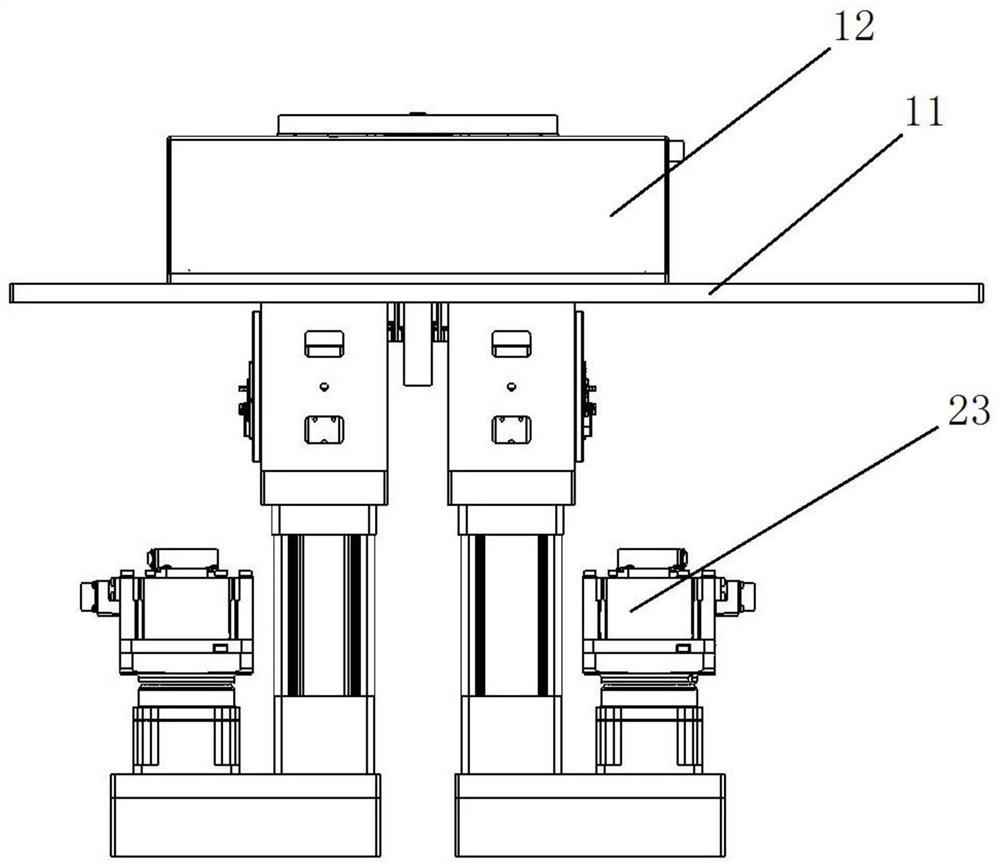

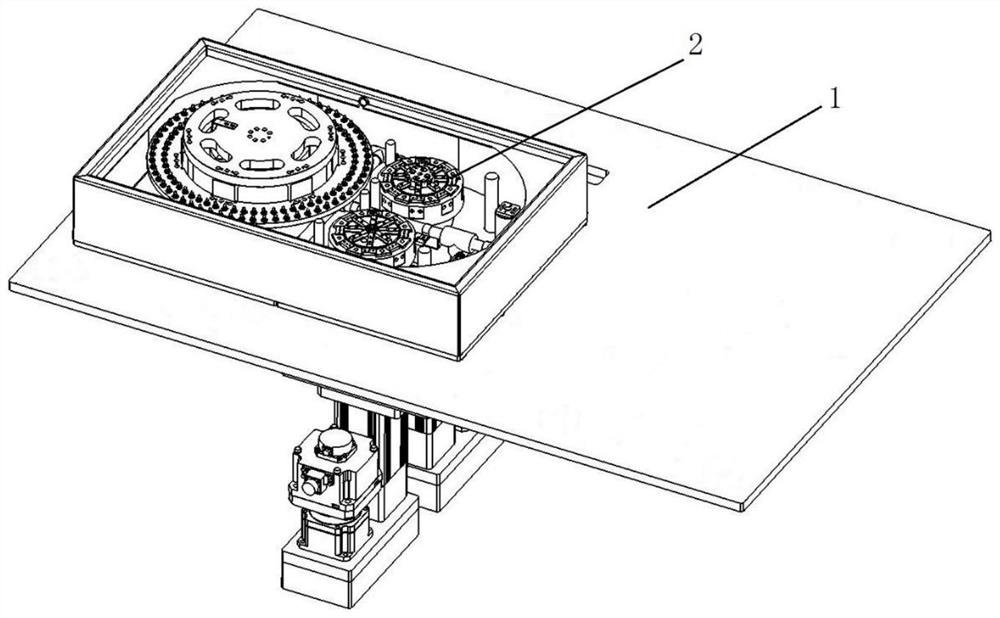

[0034] Such as Figure 1 to Figure 14 As shown, the automatic extruding structure of the present invention is usually used to heat and melt the wax bag of the automobile thermostat and extrude the wax bag to ensure that the pressure in the wax bag meets the test standard. It mainly includes the loading assembly 1 and Extrusion components 2 etc.

[0035] The loading assembly 1 is usually arranged on the test machine, and it mainly includes a bottom plate 11, a casing 12, a cylinder 121, a turntable mechanism 13 and a cover plate 14, etc., and the bottom plate 11 is fixed on the test machine by means of screw fastening. The housing 12 is fixed on the bottom plate 11 (the housing 12 is hollow and can be fixed by welding; in this embodiment, the inside of the housing 12 is separated from the outside). The cylinder body 121 is integrally formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com