AOI detection equipment

A testing equipment and visual inspection technology, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems such as the inability to meet product quality control needs, and achieve improved production line quality control and improvement. The effect of production efficiency and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

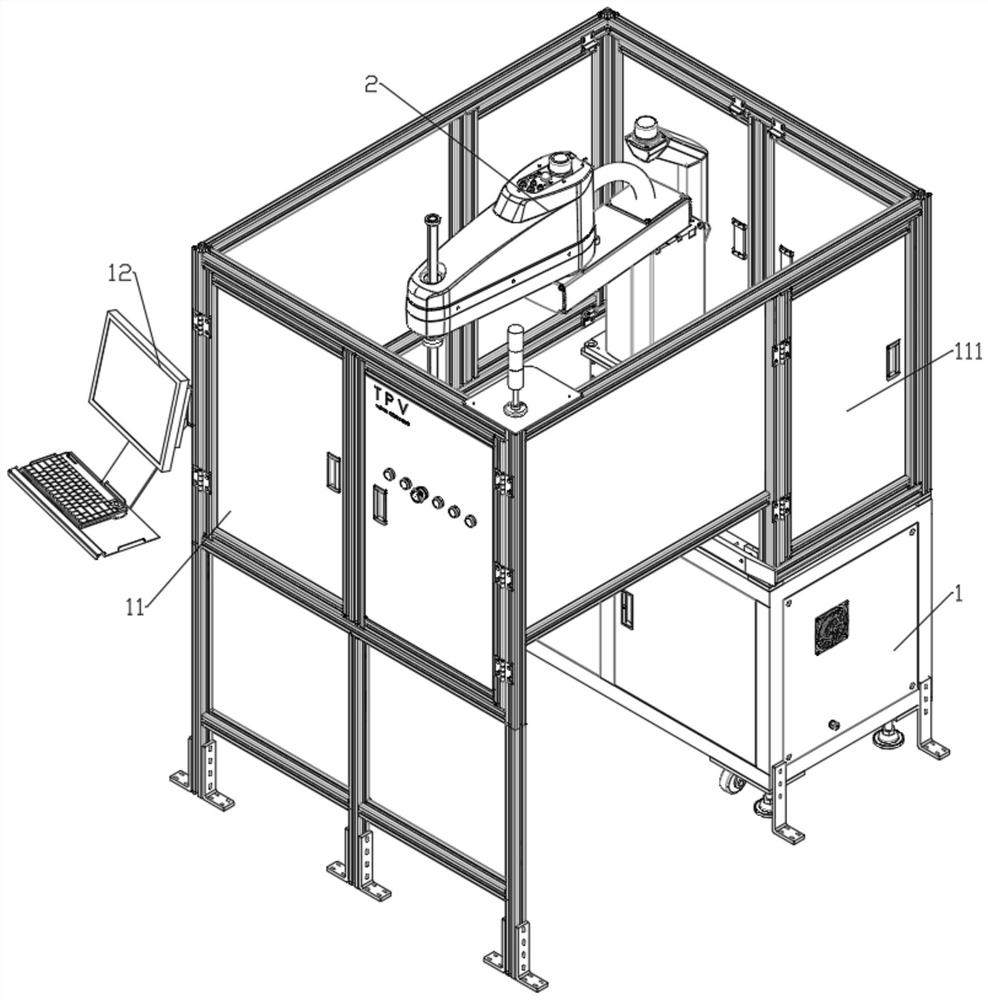

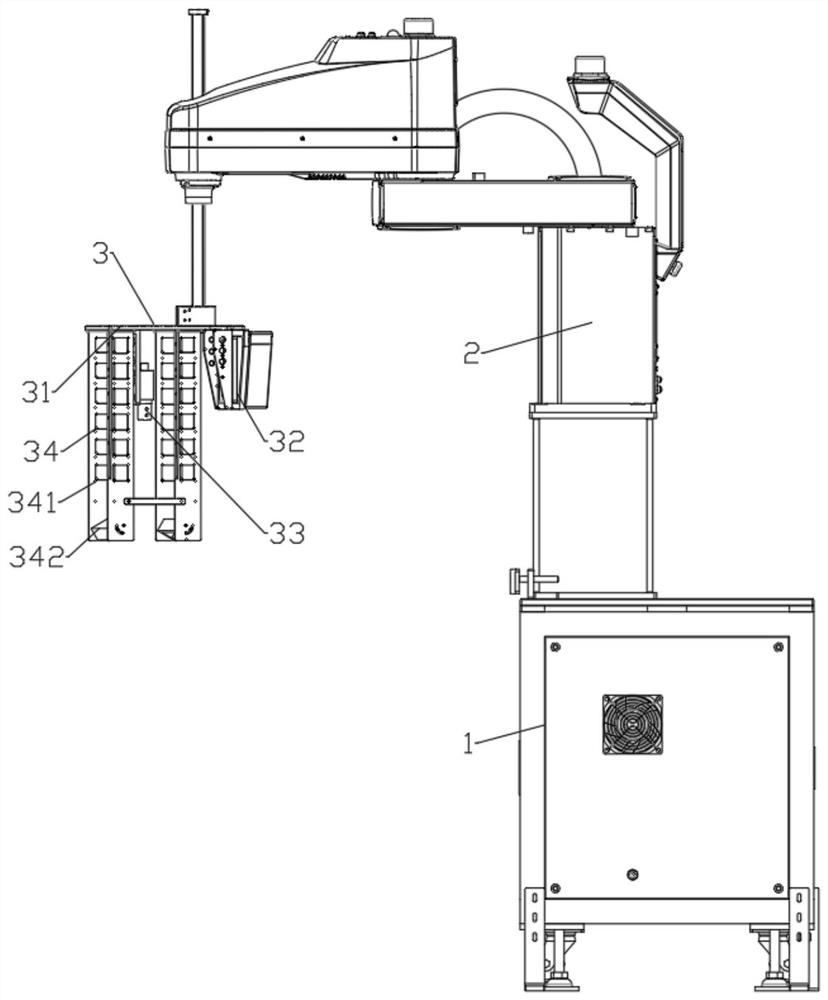

[0016] see figure 1 , figure 2 , the present invention provides an AOI detection equipment, including: a machine 1, a manipulator 2 arranged on the machine 1, a visual inspection module 3 arranged on the manipulator 2, and a machine installed in the machine 1 control system, the visual detection module 3 includes: a mounting bracket 31 disposed at the front end of the manipulator 2, a 3D imaging module 32 disposed on the mounting bracket 31, and a 3D imaging module 32 disposed on the side 2D area scan camera33. When working, the product to be detected is transported to the bottom of the visual detection module 3 through the external feeding mechanism, the manipulator 2 moves to the initial position, and the 2D area array camera 33 installed on the mounting bracket 31 checks the position and posture of the current product. Take photos and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com