Boiler flue gas detection equipment

A technology for gas detection and boiler flue, which is applied to the analysis of gas mixtures, the structural details of gas analyzers, and measuring devices. It can solve the problems of large detection errors and inconvenient sampling, so as to reduce the need for labor and avoid external interference. , the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

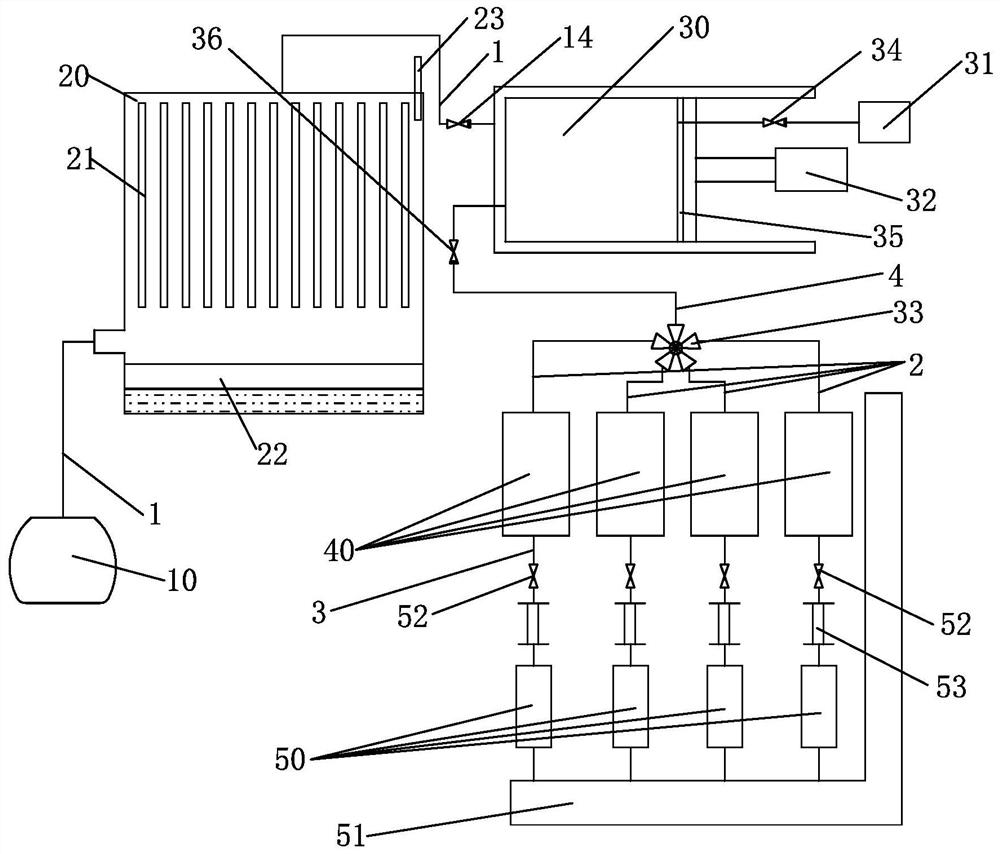

[0020] see Figure 1-2 , A boiler flue gas detection device, comprising a flue gas sampling mechanism, a dehumidification cooling mechanism, a flue gas separation mechanism, a flue gas storage mechanism, a flue gas detection mechanism, a connecting pipeline, and a control mechanism.

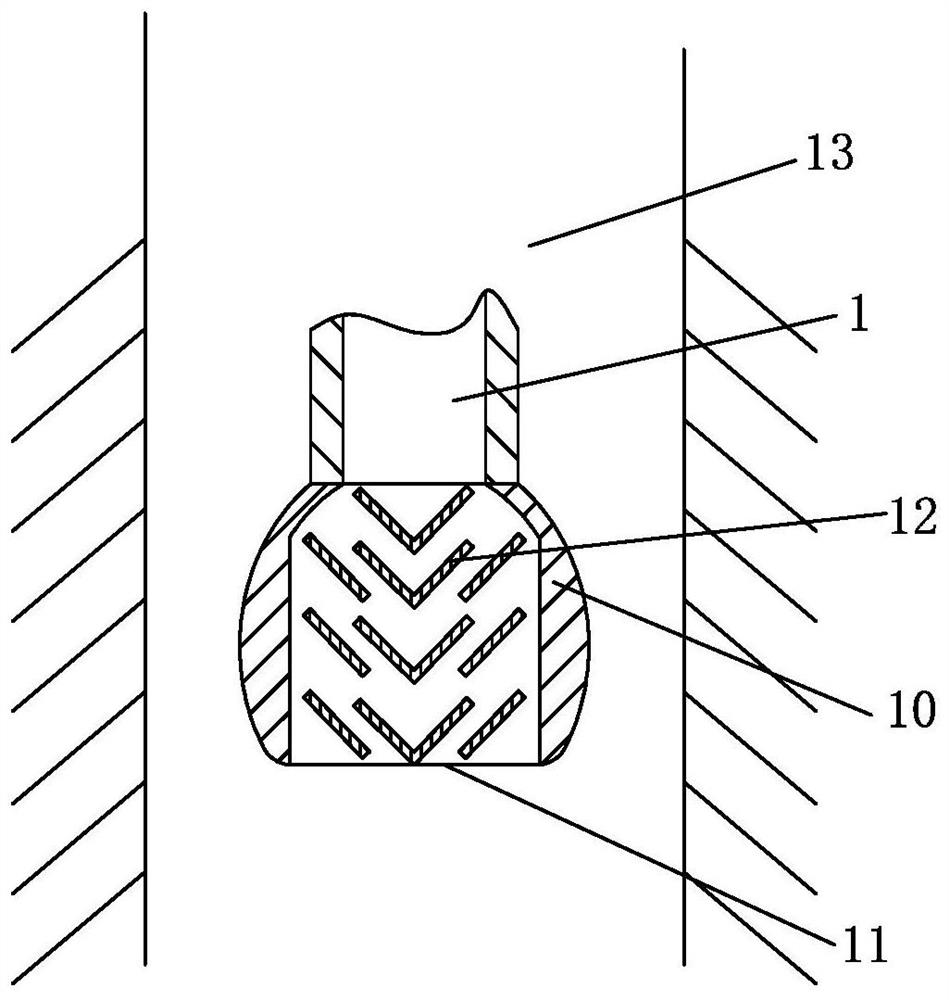

[0021] The flue gas sampling mechanism is used to extract flue gas, and includes a sampling box 10 that can be arranged in the flue 13. The bottom of the sampling box 10 is provided with a sampling port 11, and the sampling box 10 is provided with a number of inclined Arranged baffles 12. The dehumidification and cooling mechanism is used to remove moisture in the flue gas, and can be used to reduce the temperature of the flue gas to meet the detection requirements of the detector 50 . It includes a condensing box 20, a plurality of condensing plates 21 arranged in the condensing box 20, and gaps for flue gas flow are provided between the condensing plates 21. The gap between the condensing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com