Fixed-point type soil deep nutrient conveyor

A conveyor and deep-layer technology, applied in direct liquid fertilizer delivery system, liquid fertilizer distribution, fertilization device, etc., can solve the problems of excessive fertilizer penetration and absorption, unfavorable soil absorption, and difficulty in contacting fertilizer with deep soil, etc., to achieve easy Absorption, non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

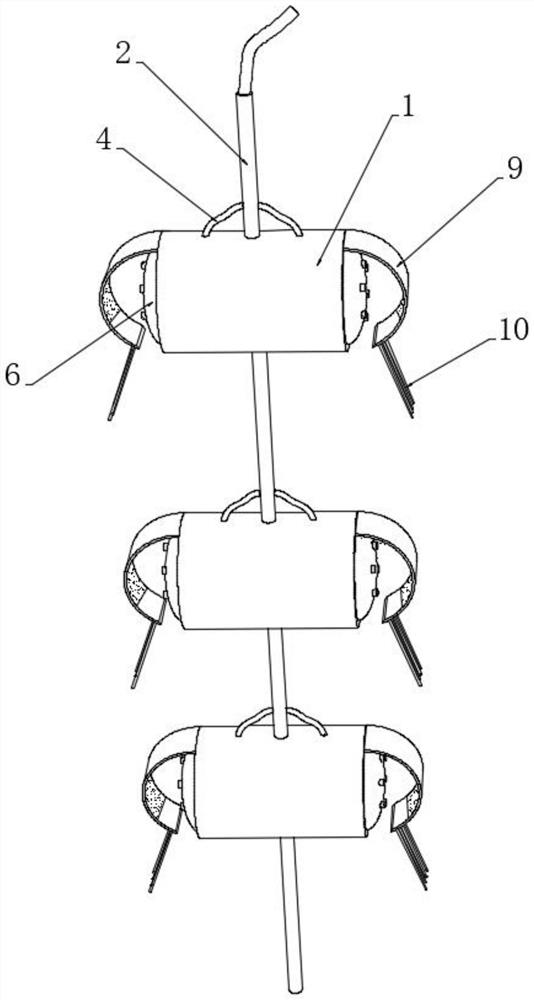

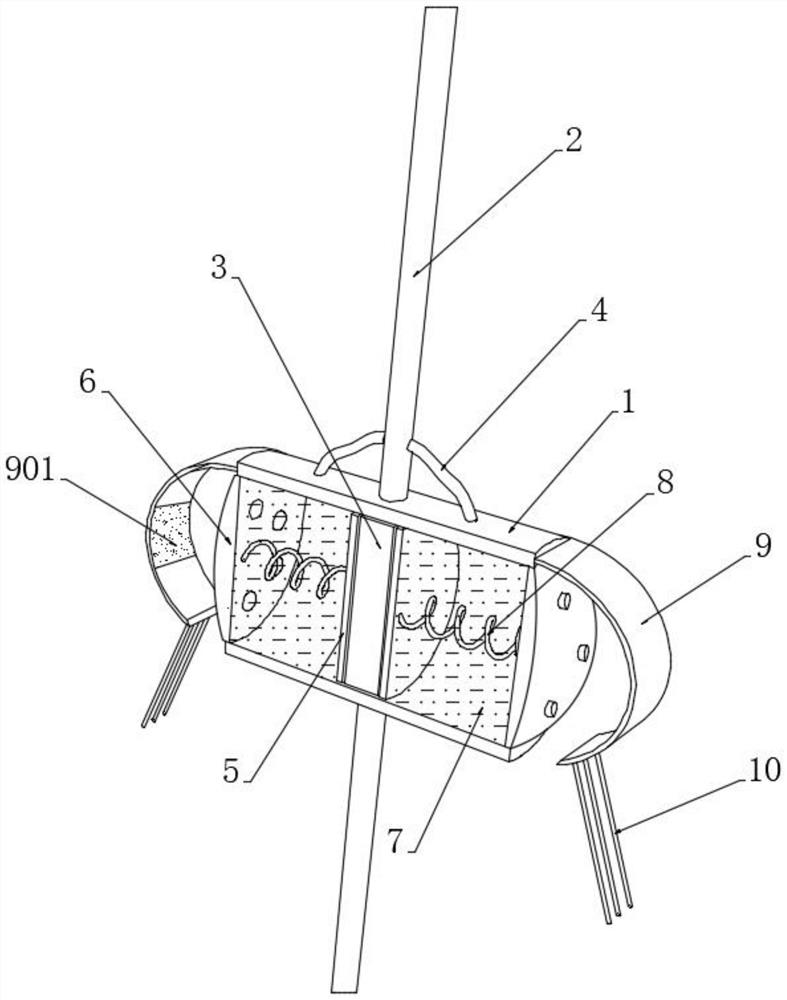

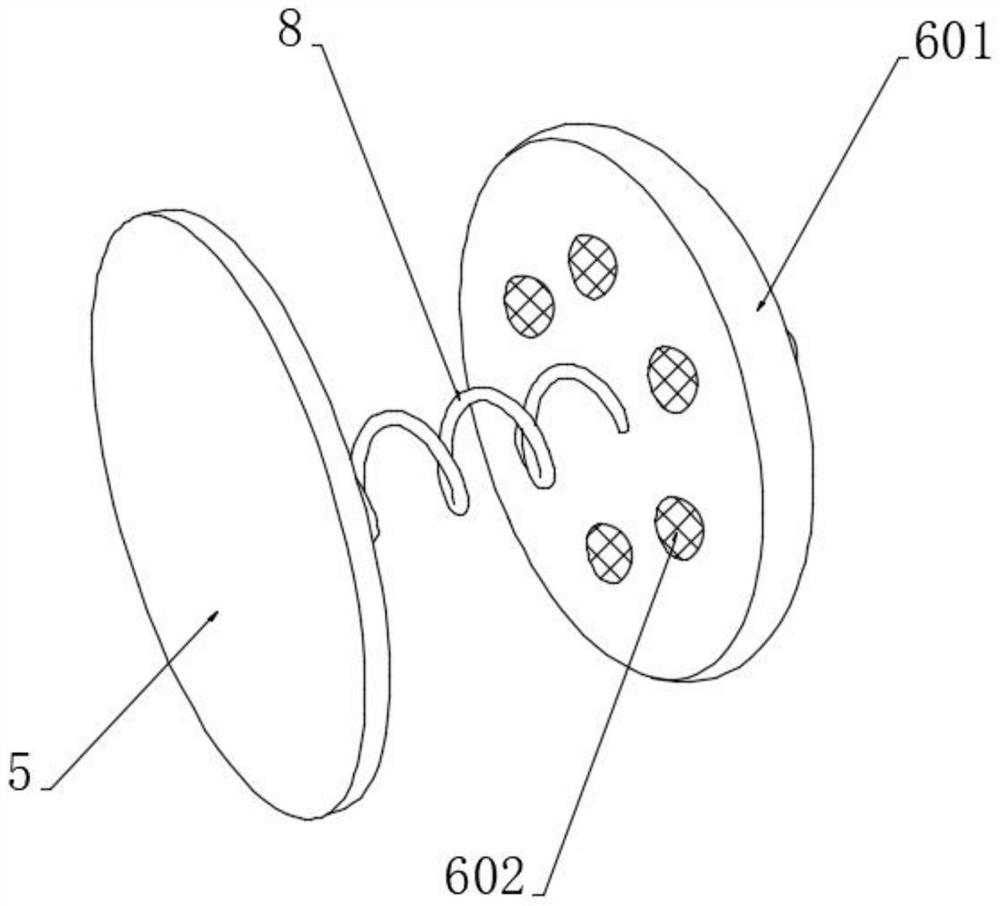

[0039] see Figure 1-4 , a fixed-point soil deep layer nutrient conveyor, comprising a pre-embedded rod 2 and a plurality of storage cylinders 1 fixedly sleeved on the side walls of the pre-embedded rod 2, the interior of the plurality of storage cylinders 1 is fixedly connected with a partition plate 3 , the partition plate 3 separates the interior of the storage cylinder 1 into two storage chambers on the left and right, and the left and right ends of the storage cylinder 1 are fixedly embedded with an outer oval permeable layer 6 that is sealed and connected with the storage chamber. The left and right sides of 3 are provided with a magnetic push plate 5 slidingly connected to the inside of the storage chamber, and the middle position of the magnetic push plate 5 is fixedly connected with the inner end of the outer oval permeable layer 6 through a tension spring 8 The insides of the two magnetic push plates 5 are all embedded with iron cores 501, the left and right ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com