Grease composition for non-dairy creamer, non-dairy creamer as well as preparation method and application of non-dairy creamer

A technology of oil composition and non-dairy creamer, which is applied in the direction of edible oil/fat, application, dairy products, etc. It can solve the problems of complex process, lack of proposal, and difficulty in meeting customer demands for oil flavor, so as to achieve refreshing taste and light flavor , good oral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

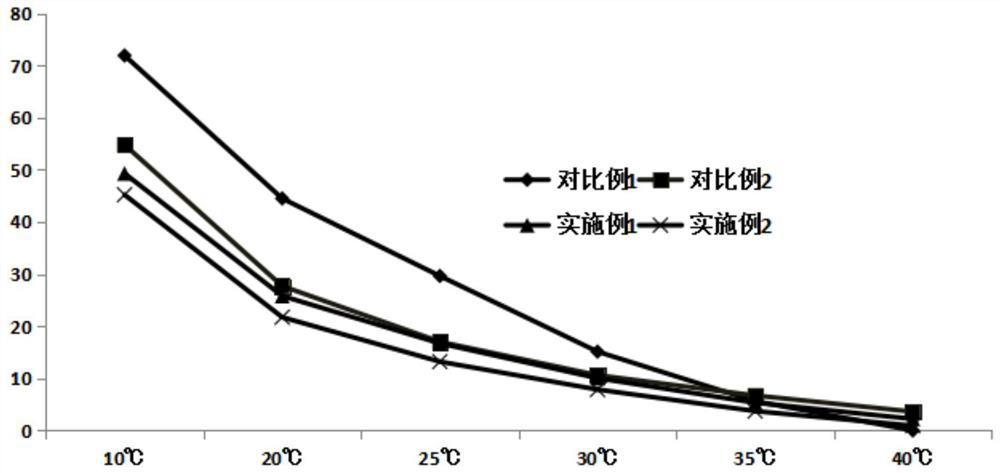

[0033]This embodiment provides a plant-lipid-forming oil-fat composition which is made of ester exchange palm oil and a split palm oil according to the mass ratio of 9: 1.

[0034]Among them, the preparation method of ester exchange palm liquid oil includes the following steps:

[0035]S1, 1 kg of palm tap, 9kg palm fraction oil (lysate ≤0-1 mg / g, color value R ≤ 2-5) is added to the reactor, and the reactor is vacuum to 5 mbar Mixed to give oil.

[0036]S2, the above oil was heated to 100 ° C, stirred and uniform, followed by stirring with sodium methoxide, stirring at a rate of 70 rpm, after 60 min, then cooled to 75 ° C, and the reaction was added to the reaction liquid Wherein, the methoxide solution is a saturated methoxide solution, which is added to 0.3% of the grease quality.

[0037]S3, the reaction solution was added to the centrifuge for centrifugation, remove moisture to obtain an ester excitation fur.

[0038]S4, the above-mentioned ester exchange fur is added to the active white so...

Embodiment 2

[0040]This embodiment provides a plant-lipid-forming oil-fat composition which is made of ester exchange palm oil and a split palm oil according to the mass ratio of 7: 3.

[0041]Among them, the preparation method of ester exchange palm liquid oil includes the following steps:

[0042]S1, 1 kg of palm tap, 9kg palm fraction oil (lysate ≤0-1 mg / g, color value R ≤ 2-5) is added to the reactor, and the reactor is vacuum to 5 mbar Mixed to give oil.

[0043]S2, the above oil was heated to 100 ° C, stirred and uniform, followed by stirring with sodium methoxide, stirring at a rate of 70 rpm, after 60 min, then cooled to 75 ° C, and the reaction was added to the reaction liquid Wherein, the methoxide solution is a saturated methoxide solution, which is added to 0.3% of the grease quality.

[0044]S3, the reaction solution was added to the centrifuge for centrifugation, remove moisture to obtain an ester excitation fur.

[0045]S4, the above-mentioned ester exchange fur is added to the active white so...

Embodiment 3

[0047]This embodiment provides a plant-free grease composition, which is made of ester exchange palm oil and a split palm oil according to the mass ratio of 5: 5.

[0048]Among them, the preparation method of ester exchange palm oil includes the following steps:

[0049]S1, 10 kg of palm fraction oil (acid value ≤0-1 mg / g, color value R ≤ 2-5) was added to the reactor, and mixed the reactor vacuum to 0 mbar for mixing to give oil.

[0050]S2, the above oil was heated to 80 ° C, and the mixture was stirred, followed by stirring with a sodium methoxide solution, stirring at a rate of 50 rpm, and then cooled to 70 ° C, and the reaction was added to the reaction liquid. Wherein, the methoxide solution is a saturated methoxide solution, which is added to 0.1% of the grease quality.

[0051]S3, the reaction solution was added to the centrifuge for centrifugation, remove moisture to obtain an ester excitation fur.

[0052]S4, the above-mentioned ester exchanger is added to the active white soil for sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com