Laser processing control method, device, equipment and computer storage medium

A laser processing and control method technology, which is applied in the field of devices, laser processing control methods, equipment and computer storage media, can solve the problems that the coaxial consistency between the laser scanning beam and the gas nozzle cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

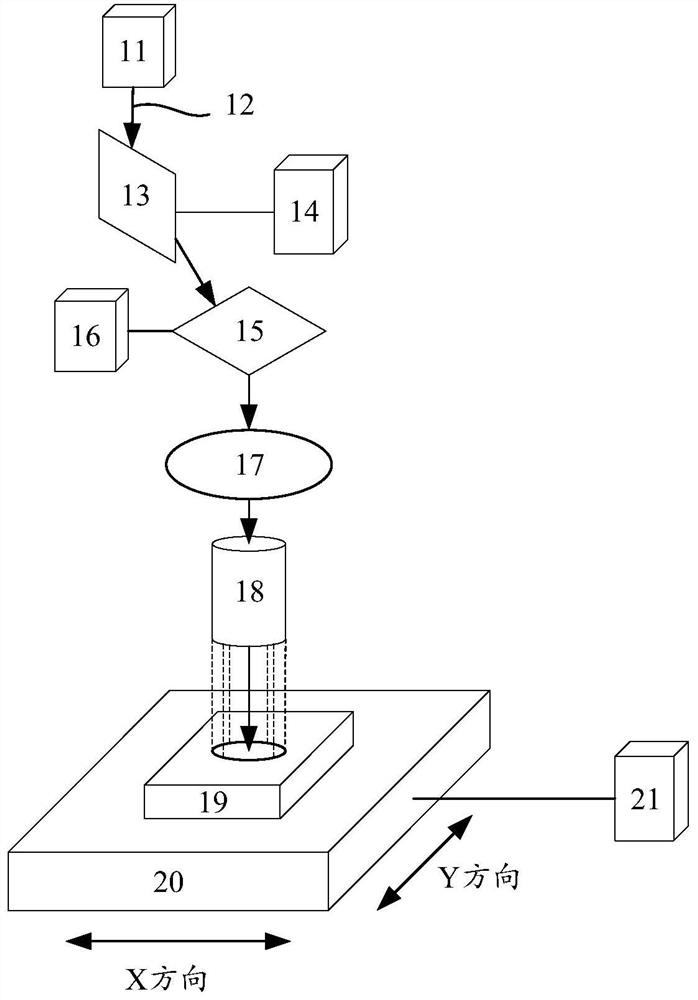

[0043] see figure 1 , which shows a laser processing equipment 1 capable of implementing the technical solutions of the embodiments of the present invention, understandably, figure 1 It only exemplarily shows the components and details related to the technical solution, and does not show other possible components and details of the laser processing equipment, and does not limit the specific processing parameters. Such as figure 1 As shown, the laser processing equipment 1 may include: a laser 11; a two-dimensional scanning vibrating mirror composed of an X-axis mirror 13, an X-axis driving motor 14, a Y-axis mirror 15 and a Y-axis driving motor 16, hereinafter referred to as a scanning Vibrating mirror or vibrating mirror; Field mirror 17; Coaxial air nozzle 18; Servo platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com