Numerical control machine tool for oil smoke separation treatment

A CNC machine tool and oil fume separation technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inability to filter iron filings, affect the health of workers, and environmental pollution at the work site, and achieve saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

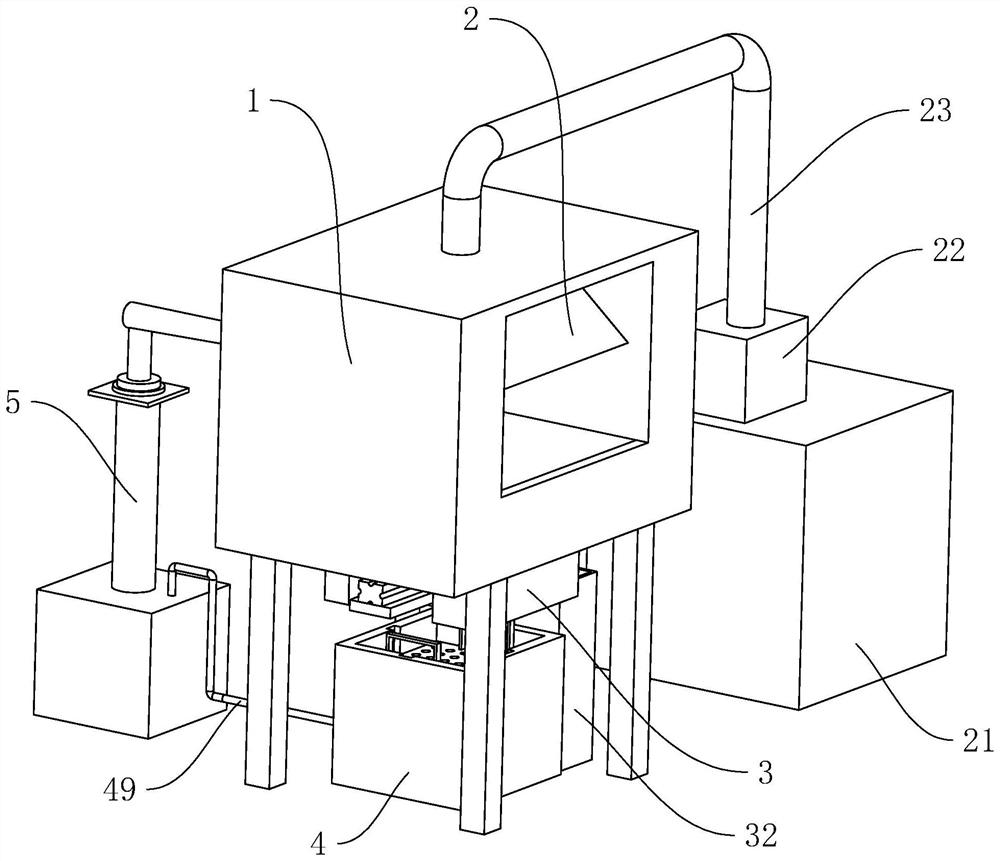

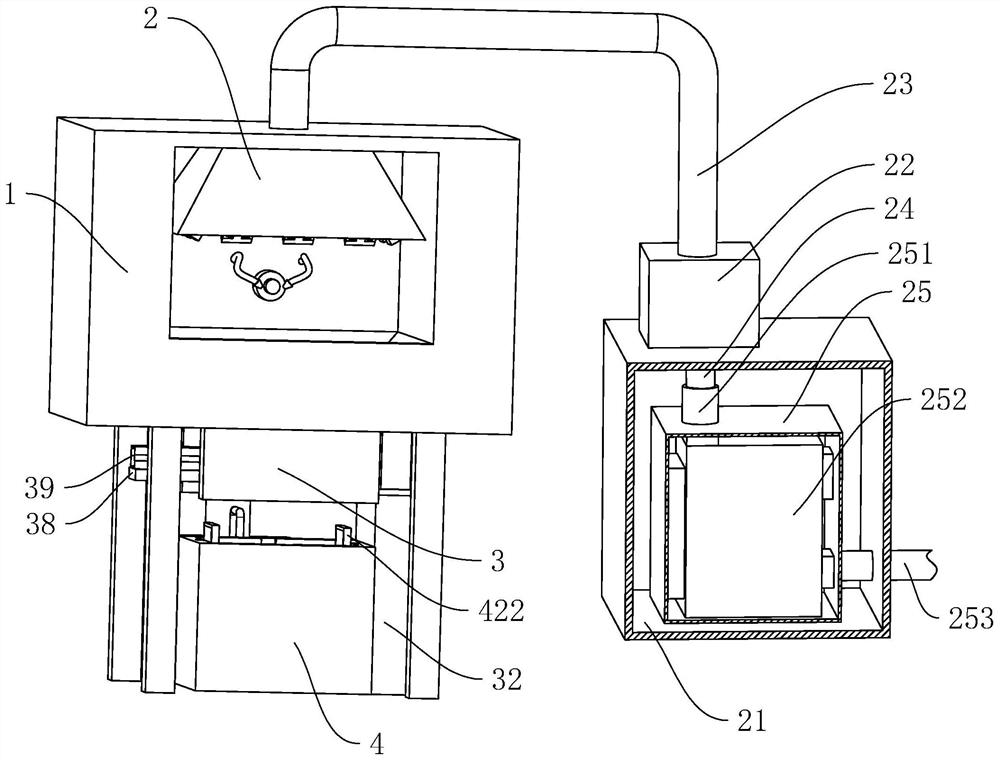

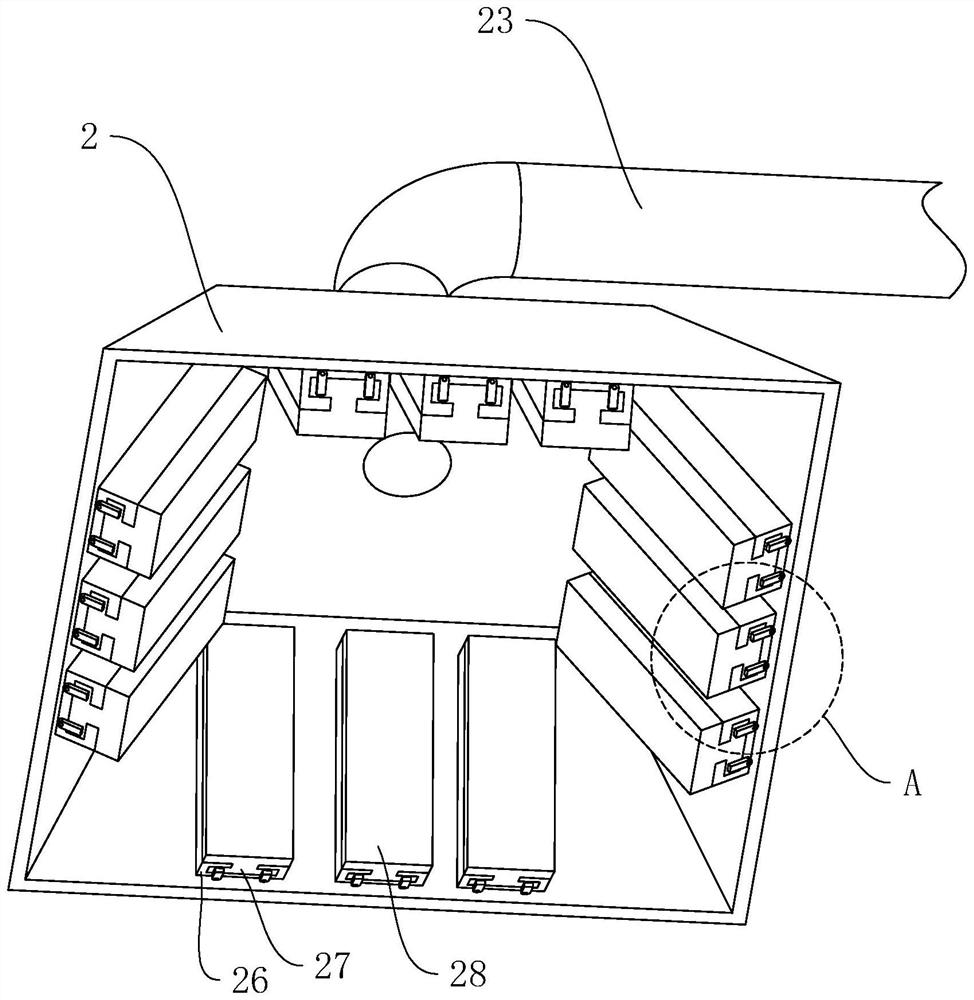

[0040] The following is attached Figure 1-7 The application is described in further detail.

[0041] The embodiment of the present application discloses a numerically controlled machine tool for oil fume separation and treatment. refer to figure 1 , the CNC machine tool includes a machine tool body 1, which is used for cutting the workpiece inside the machine tool body 1, and an oil spraying device 5 is arranged on one side of the machine tool body 1, and the spray head of the oil spraying device 5 cuts the workpiece Spray cooling oil at the position to cool the workpiece; and when the cooling oil contacts the high-temperature workpiece, a large amount of oil mist will be generated, and the oil mist floats inside the machine tool body 1. A large amount of harmful substances are mixed and directly discharged into the workshop, which will not only pollute the environment of the work site, but also affect the health of the staff.

[0042] Therefore, in order to deal with thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com