Solvent-free printing compound machine and solvent-free printing compound process

A compound process and solvent-free technology, which is applied to printing machines, rotary printing machines, gravure rotary printing machines, etc., can solve the problems of wasting manpower and time, unstable finished product quality, incoherent work, etc., and achieve fast working speed and saving The effect of manpower and work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

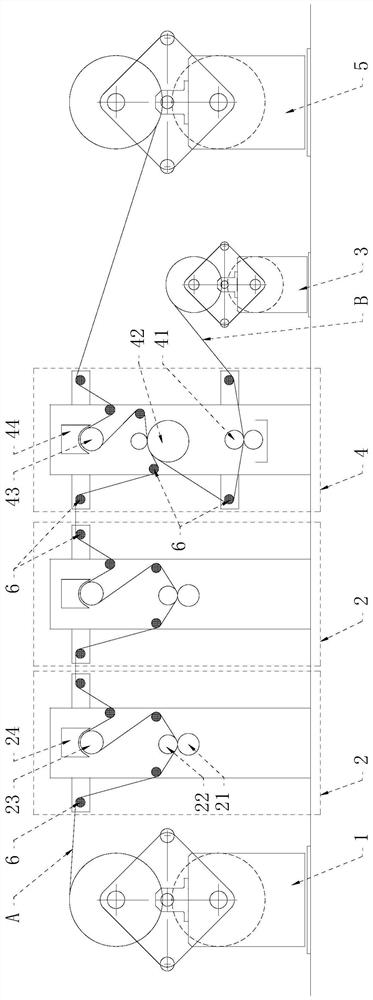

[0035] like figure 1 As shown, the present invention includes a solvent-free printing compound machine, comprising:

[0036] Paper unwinding device 1, described paper unwinding device 1 is used for inputting substrate A;

[0037] A multi-color printing unit, the multi-color printing unit includes several groups of printing units 2 connected in series, several groups of the printing units 2 are arranged behind the paper unwinding device 1 and are respectively used for printing on the substrate A, and the plurality of printing units 2 each printing a single color, and the printing unit 2 is a solvent-free gravure printing device;

[0038] Film unwinding device 3, described film unwinding device 3 is used for inputting sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com