Microwave denitration device

A microwave and denitration technology, used in reactor fuel elements, inorganic chemistry, nuclear power generation, etc., can solve problems such as loss of nuclear materials, dilute solutions, complex processes and equipment, and achieve the effect of small waste and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

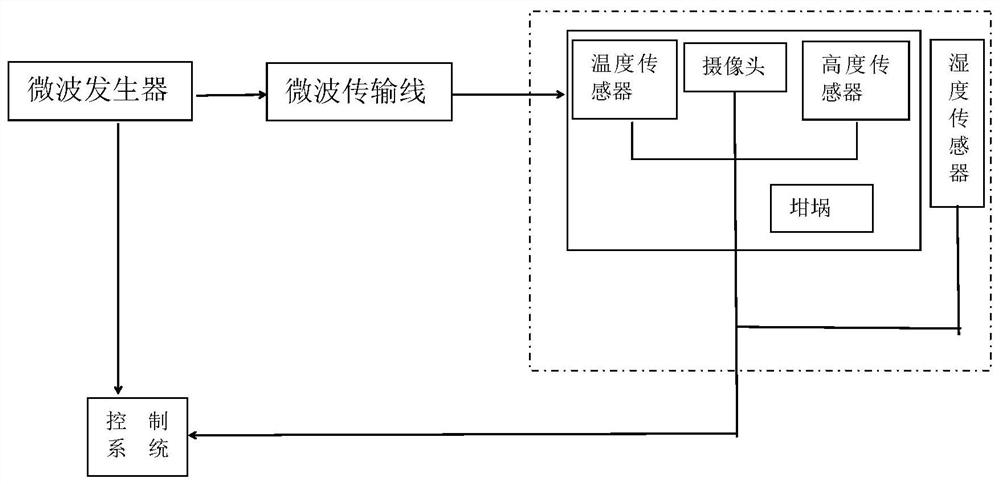

[0028] Such as figure 1 As shown, a microwave denitrification device is used to convert neptunium / plutonium nitrate solution into neptunium / plutonium oxide powder; the device consists of a microwave generator, a microwave transmission line, a control system, a radioactive sealed chamber, and a microwave cavity and material containers.

[0029] The microwave generator, microwave transmission line, and control system are located outside the radioactive sealed chamber (non-radioactive area); the microwave cavity and the material container are located inside the radioactive sealed chamber (radioactive area); the material container is located in the microwave cavity Inside, the material container is a crucible, which is used to hold the neptunium / plutonium nitrate solution. The material container is the main place where the denitration reaction occurs. The neptunium / plutonium nitrate solution is gradually converted into oxides by microwave heating. The material of the microwave ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com