Alpha-type high-strength gypsum

A high-strength, gypsum technology, applied in the field of gypsum, can solve the problems of large difference in product quality, complex post-processing process, and high impurity content, and achieve the effects of high grade, strong mechanical strength, and simple post-processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

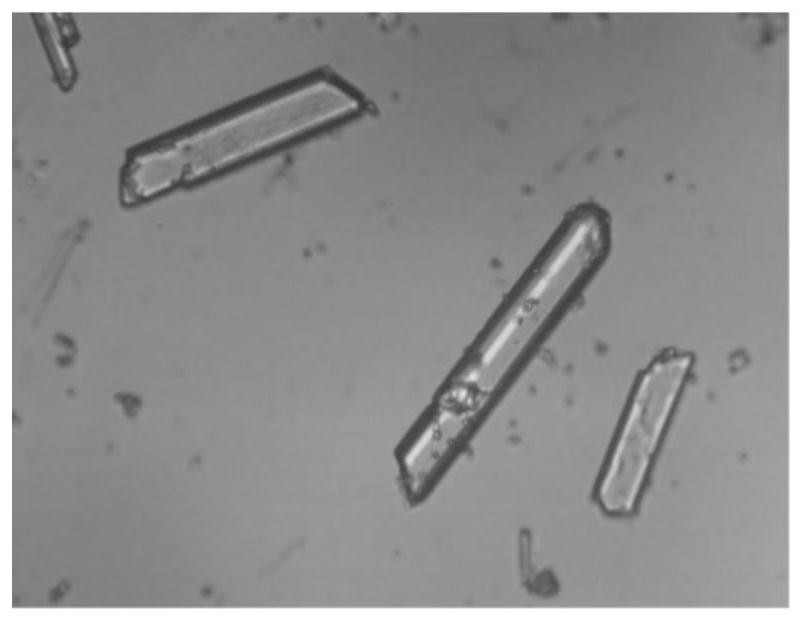

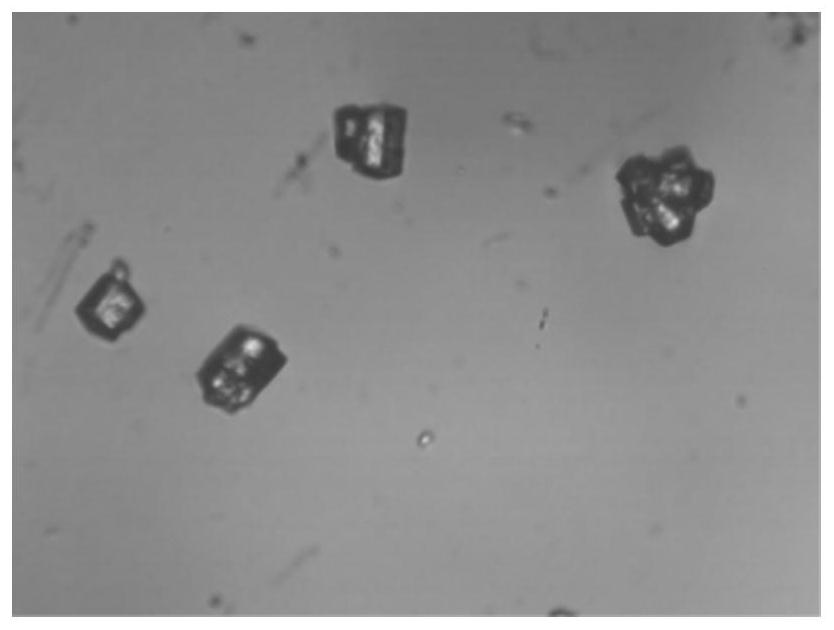

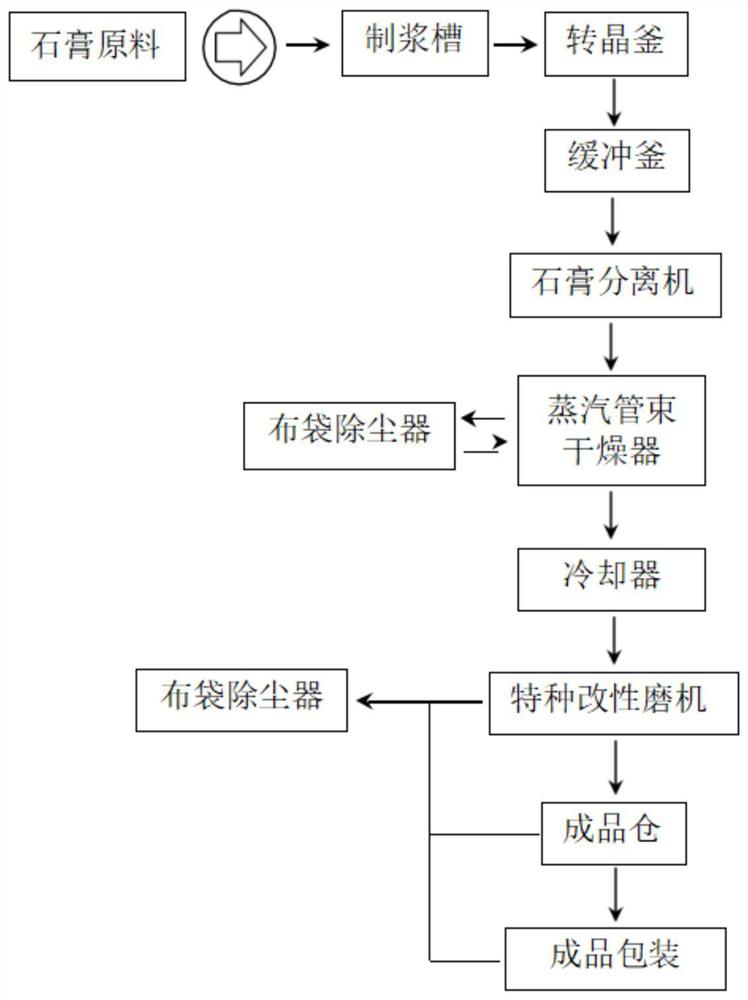

Image

Examples

Embodiment 1

[0048] The preparation method of α-type high-strength gypsum comprises the following steps:

[0049] Preparation of Salt Gypsum:

[0050] (1) Soda ash light calcium liquid is injected into Glauber's salt type brine wells to extract brine to obtain nitric brine, low nitric brine, and calcium brine respectively; condensed water and salt-making exhausted water are injected into brine wells to obtain nitric brine;

[0051] (2) Nitrate and calcium brine are reacted at a volume ratio of 1:0.2-1:0.6 to obtain low-nitrate brine, and the precipitate in the reaction is collected to obtain the salt-containing (NaCl) gypsum.

[0052] Preparation of α-type high-strength gypsum:

[0053] 1) Condensed water washes and desalts the salt-containing (NaCl) gypsum, and then filters to obtain calcium sulfate dihydrate;

[0054] 2) adding the calcium sulfate dihydrate obtained in step 1) into an aqueous solution of a crystal-transforming agent, stirring to make the aqueous solution of the crystal...

Embodiment 2

[0061] The preparation method of α-type high-strength gypsum comprises the following steps:

[0062] Preparation of Salt Gypsum:

[0063] (1) Soda ash light calcium liquid is injected into Glauber's salt type brine wells to extract brine to obtain nitric brine, low nitric brine, and calcium brine respectively; condensed water and salt-making exhausted water are injected into brine wells to obtain nitric brine;

[0064] (2) Nitrate and calcium brine are reacted at a volume ratio of 1:0.2-1:0.6 to obtain low-nitrate brine, and the precipitate in the reaction is collected to obtain the salt-containing (NaCl) gypsum.

[0065] Preparation of α-type high-strength gypsum:

[0066] 1) Condensed water washes and desalts the salt-containing (NaCl) gypsum, and then filters to obtain calcium sulfate dihydrate;

[0067] 2) adding the calcium sulfate dihydrate obtained in step 1) into an aqueous solution of a crystal-transforming agent, and stirring to make the aqueous solution of the cry...

Embodiment 3

[0074] The preparation method of α-type high-strength gypsum comprises the following steps:

[0075] Preparation of Salt Gypsum:

[0076] (1) Soda ash light calcium liquid is injected into Glauber's salt type brine wells to extract brine to obtain nitric acid water, low-nitrate brine, and calcium brine respectively; condensed water and salt-making exhausted water are injected into brine wells to obtain nitric brine;

[0077] (2) Nitrate and calcium brine are reacted at a volume ratio of 1:0.2-1:0.6 to obtain low-nitrate brine, and the precipitate in the reaction is collected to obtain the salt-containing (NaCl) gypsum.

[0078] Preparation of α-type high-strength gypsum:

[0079] 1) Condensed water washes and desalts the salt-containing (NaCl) gypsum, and then filters to obtain calcium sulfate dihydrate;

[0080] 2) adding the calcium sulfate dihydrate obtained in step 1) into an aqueous solution of a crystal-transforming agent, stirring to make the aqueous solution of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com