Environment-friendly flame-retardant expandable polystyrene resin and preparation method thereof

An expandable polystyrene, flame retardant technology, applied in the field of polystyrene resin, can solve the problems of reducing production efficiency, increasing costs, increasing the dosage of flame retardants, etc. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

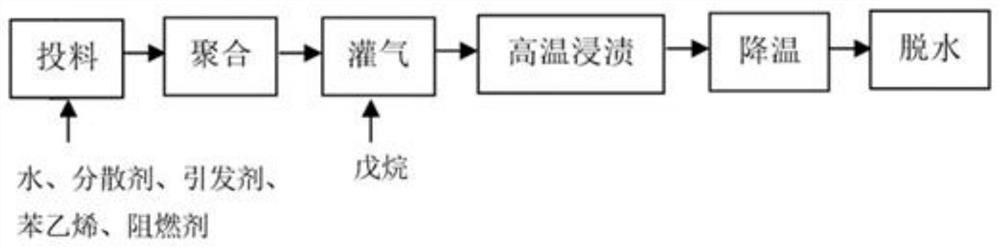

Method used

Image

Examples

Embodiment 1

[0020] Pour 115 parts of desalinated water into the reactor, add 2.6 parts of calcium phosphate and 0.0003 parts of sodium sulfonate successively under uniform stirring, and continue stirring for 8 minutes. Add 50 parts of styrene and 0.2 parts of benzoyl peroxide in sequence, and heat the reactor at a heating rate of 0.9°C / min. When the temperature rises to 89°C, keep the constant temperature for 125 minutes.

[0021] Add the remaining 50 parts of styrene, the remaining 0.2 parts of benzoyl peroxide, 0.5 parts of dicumyl peroxide, 0.8 parts of brominated styrene-butadiene-styrene block copolymer and 0.2 parts of structure regulator, wherein The regulator is linear polyethylene or branched polyethylene, and continue to heat the reactor. When the temperature rose to 88°C, the temperature was maintained for 330 minutes to make the material form granules.

[0022] Add 4.5 parts of pentane, and continue to heat the reactor until the temperature reaches 120° C., and the pressure i...

Embodiment 2

[0026] Pour 130 parts of desalted water into the reactor, add 4.0 parts of calcium phosphate and 0.0005 parts of sodium sulfonate successively under uniform stirring, and continue stirring for 10 minutes. Afterwards, 55 parts of styrene and 0.25 parts of benzoyl peroxide were successively added, and the reactor was heated at a heating rate of 1.2° C. / min. When the temperature rose to 93° C., the temperature was maintained for 150 minutes.

[0027] Add the remaining 55 parts of styrene, the remaining 0.25 parts of benzoyl peroxide, 0.6 parts of dicumyl peroxide, 0.9 parts of brominated styrene-butadiene-styrene block copolymer and 0.3 parts of structure regulator , wherein the regulator is linear polyethylene or branched polyethylene, and continue to heat the reactor. When the temperature rises to 90°C, keep the constant temperature for 300 minutes to make the material form granules.

[0028] Add 4.0 parts of pentane, and continue to heat the reactor until the temperature reac...

Embodiment 3

[0032] Pour 100 parts of desalted water into the reactor, add 1.2 parts of calcium phosphate and 0.0002 parts of sodium sulfonate successively under uniform stirring, and continue stirring for 5 minutes. Afterwards, 45 parts of styrene and 0.15 parts of benzoyl peroxide were added in sequence, and the reactor was heated at a heating rate of 0.6° C. / min. When the temperature rose to 85° C., the temperature was maintained for 100 minutes.

[0033] Add the remaining 45 parts of styrene, the remaining 0.15 parts of benzoyl peroxide, 0.3 parts of dicumyl peroxide, 0.75 parts of brominated styrene-butadiene-styrene block copolymer and 0.1 part of structure regulator , wherein the regulator is linear polyethylene or branched polyethylene, and continue to heat the reactor. When the temperature rises to 85°C, keep the constant temperature for 360 minutes to make the material form granules.

[0034] Add 5.0 parts of pentane, and continue to heat the reactor until the temperature reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com