Connector for electrolytic powder processing, electrolytic powder processing device and manufacturing method

A powder making device and connector technology, which is applied in the direction of connection, coupling device, electrolytic components, etc., can solve the problems of unsatisfactory long-term continuous use, relatively high requirements for the flatness of the pole plate, and the inconvenient movement of the pole plate, etc., to achieve Simple and convenient installation, good contact, and the effect of reducing contact voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

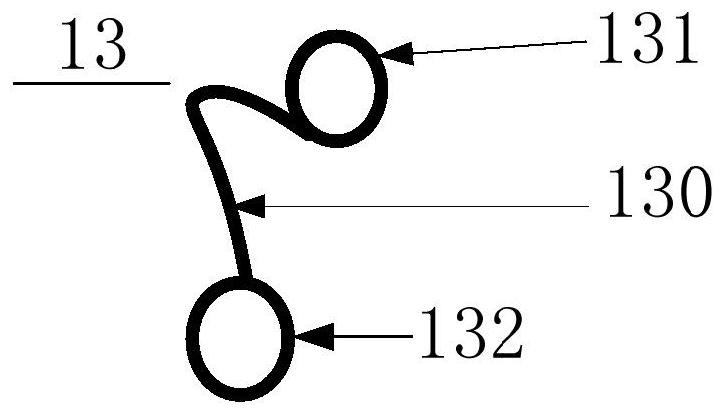

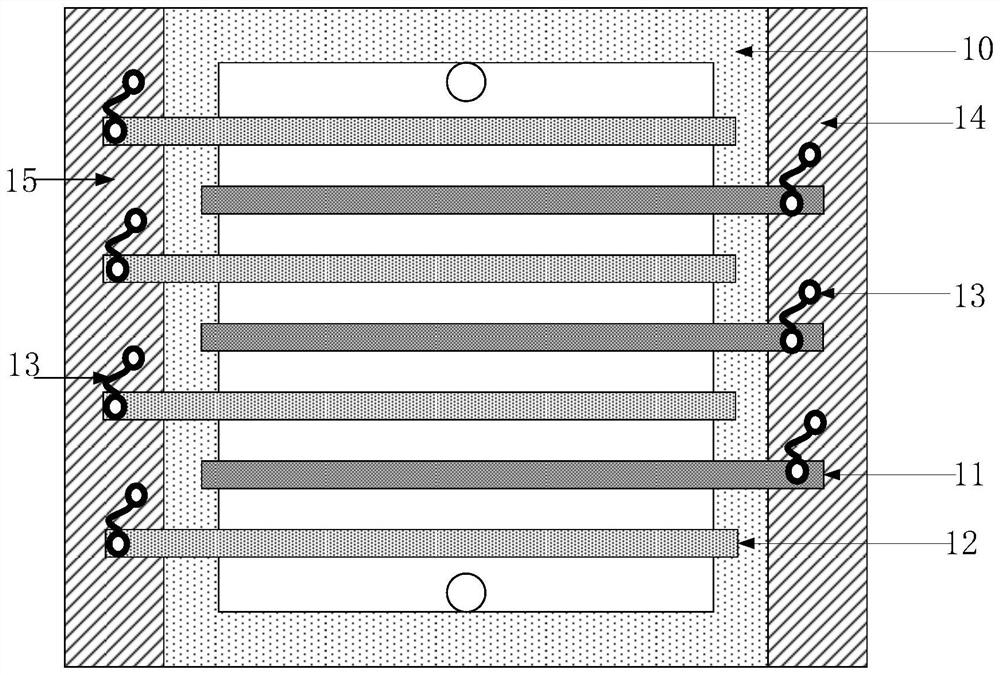

[0030] 200 pure copper wires with a diameter of 1mm and a length of 500mm are used as the flexible conductive body 130, and the two ends are placed in a pure copper tube with an inner hole of 10.5mm, a length of 20mm, and a wall thickness of 2mm (as the first fixed end 131 or the second fixed end. 132), and then through 900°C and 100MPa hot pressing, the copper wire and copper tube are welded into a connector 13 of 8*30*20mm, and the allowable current of this connector is no more than 2000A.

[0031] Please refer to Figure 1-2 , the electrolytic cell 10 is filled with an electrolyte solution, and under the conditions of the electrolytic copper powder with the voltage of the electrolytic cell 10 being 2.03V, 3000A, three cathode plates 11 and four anode plates 12, the cathode plate 11 of the commonly used direct lapping method is adopted The contact voltage with the first conductive busbar is 0.09-0.11V, and the connector 13 of the present invention is used instead, wherein th...

Embodiment 2

[0034] The surface of the first fixed end 131 of the connector 13, the second fixed end 132 and the contact part of the pole plate and the conductive bus bar are coated with a layer of conductive paste, and other conditions are the same as in Example 1, the cathode plate 11 and the first conductive bus bar 14 The contact voltage drop is 0.01-0.02V, the average drop is 85%, and the energy consumption is reduced by 4.2%.

Embodiment 3

[0036] The surface of the first fixed end 131 of the connector 13, the second fixed end 132 and the contact part of the pole plate and the conductive bus bar are coated with a layer of conductive paste, and a U-shaped stainless steel block (thickness 10mm, the size ratio of the U-shaped groove is fixed) 0.05-0.1mm) and heating to 400-500°C, directly fix the fixing member and the pole plate (or conductive busbar) together, and other conditions are the same as in embodiment 1. The contact voltage drop between the cathode plate 11 and the conductive busbar is 0.00-0.01V, with an average drop rate of 95%, and the energy consumption is reduced by 4.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com