Cotton thread needling device for textile processing

A cotton thread and thread rod technology, which is applied in the field of cotton thread needle devices for textile processing, can solve the problems of single structure, large space occupied by the needle device, and affecting the efficiency of textile processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

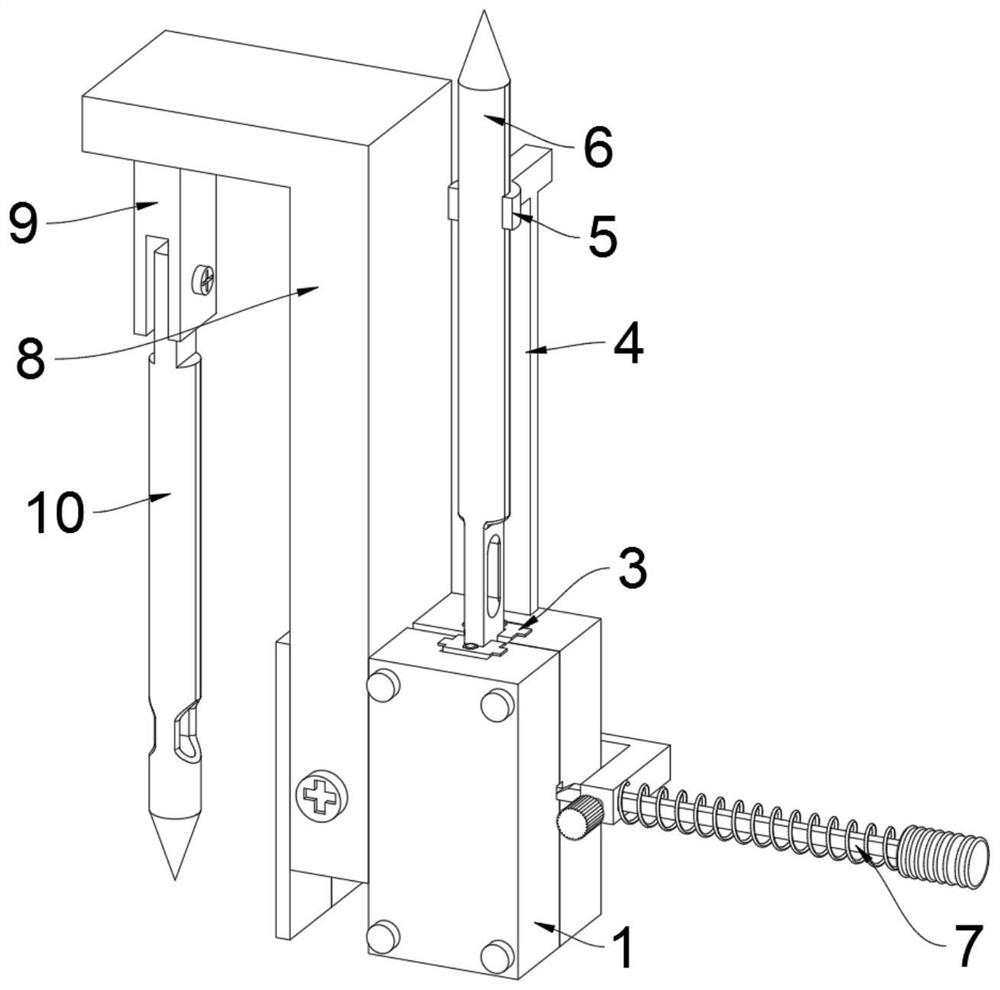

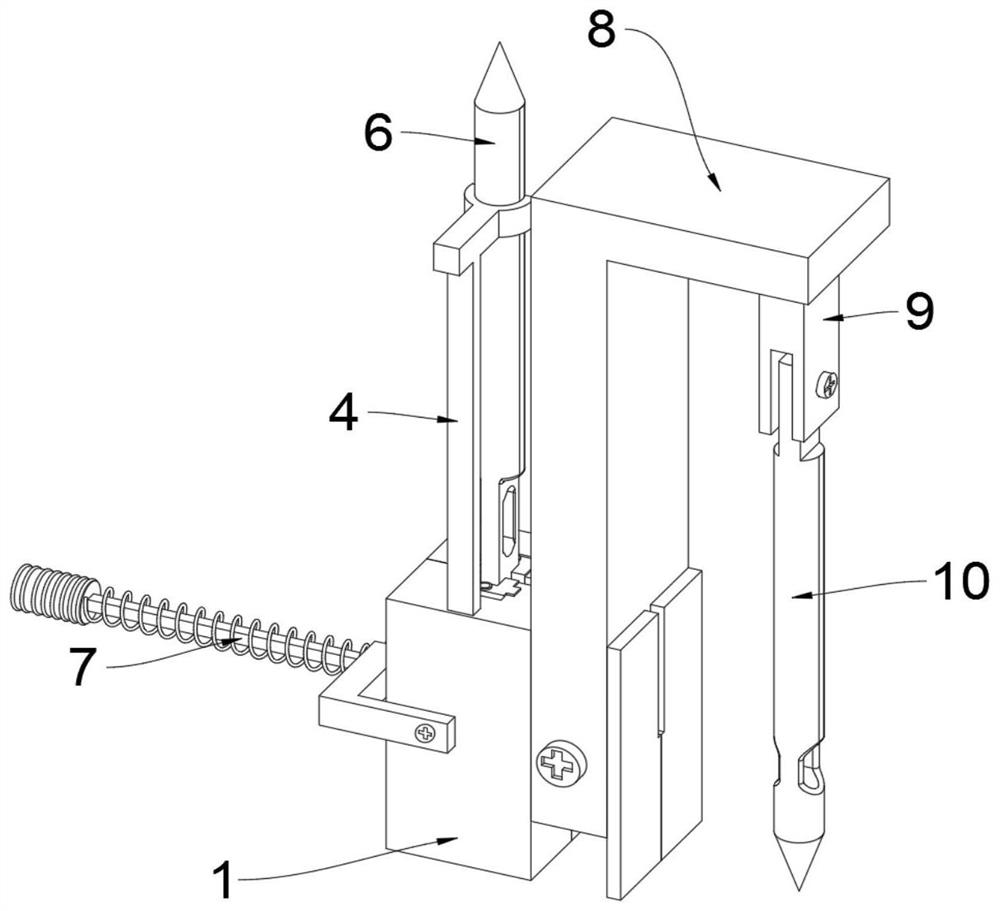

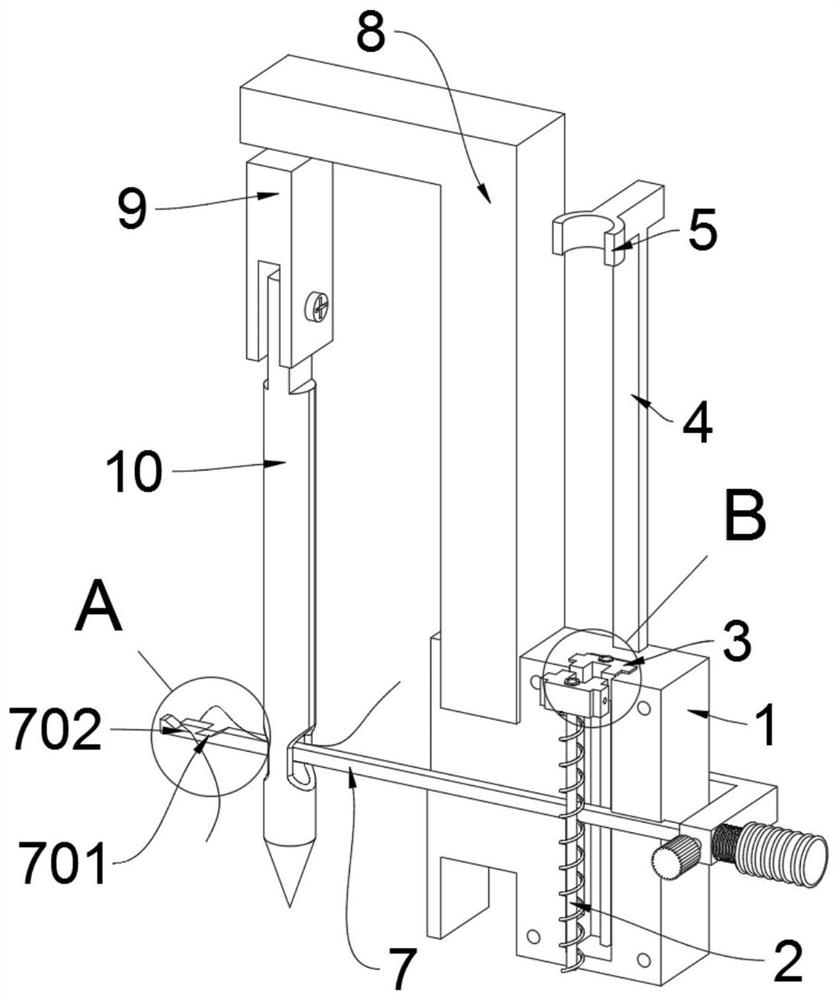

[0034]Appendfigure 1 AdherentFigure 8Down:

[0035]The present invention provides a woven fabric on a woven process, including a protective case 1; two restricted rods 2 are mounted on the protective case 1, and a sliding block 3 is mounted on the restricted rod 2; the protective case 1 includes a connection Block 101, the connection block 101 is fixed to the protective case 1 by a fixed bolt, and a rectangular hole is opened on the connection block 101, and the threading rod 7 is slidably connected to the rectangular hole, and the connection block 101 is mounted with a relatively positive bolt with the threading rod 7, When used, the connection block 101 functions as a support of the threaded rod 7, and the bolts on the connecting block 101 functions as fixed to the threaded rod 7; the protective case 1 is mounted on the protective case 1, and there is a card on the connecting rod A4. The buckle 5 is mounted on the buckle 5, and the bottom of the sewing needle A6 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com