A Closed Heat Pump Drying System with Network Recombination of Multiple Heat Exchangers

A heat pump drying and heat exchanger technology, applied in drying, dryer, heating device and other directions, can solve the problem of not considering air circulation pre-cooling and preheating, etc., to improve dehumidification energy efficiency, reduce cycle pressure ratio, The effect of fast dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

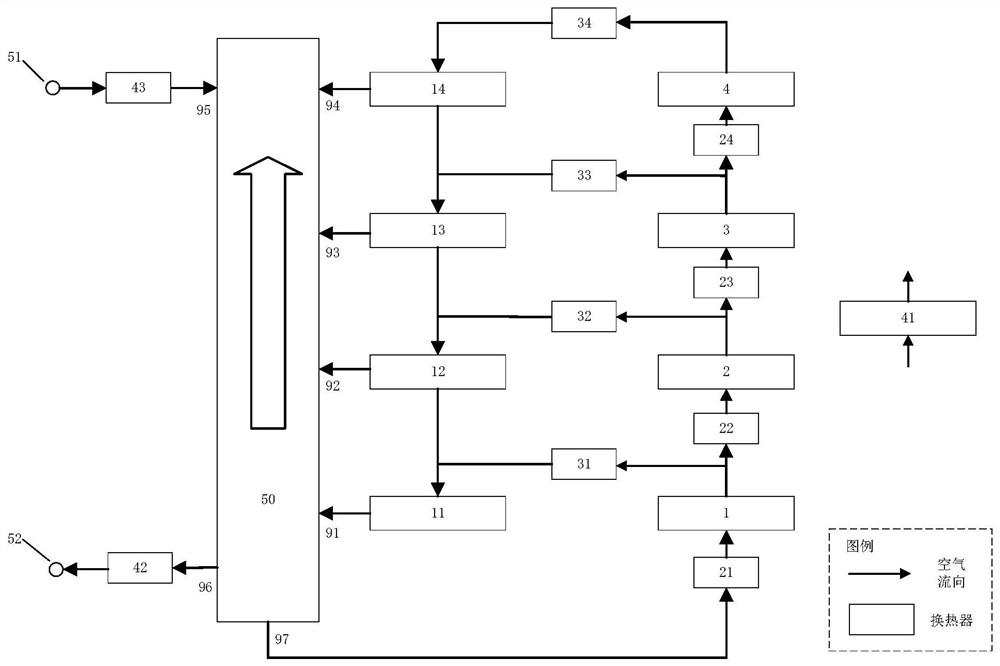

[0136] The closed heat pump drying system recombined with multi-heat exchanger network in this embodiment includes a heat exchanger network, a drying tunnel, and air circulation, refrigerant circulation and heat pipe circulation connecting each heat exchanger.

[0137] The heat exchanger network includes evaporators, condensers, auxiliary heat exchangers (pre-cooling heat exchangers and pre-heating heat exchangers, outdoor heat exchangers), etc. For a closed drying system, the number of the above-mentioned heat exchangers is not limited. In this patent, a closed drying system with multiple heat exchangers including four pairs of evaporators and condensers is used as an example for illustration. In the case of changing the substantial structure of the heat exchanger network, increasing or decreasing the number of heat exchangers is within the scope of protection of this patent.

[0138] The items to be dried in the drying tunnel 50 move with the conveyor belt, and along the mov...

Embodiment 2

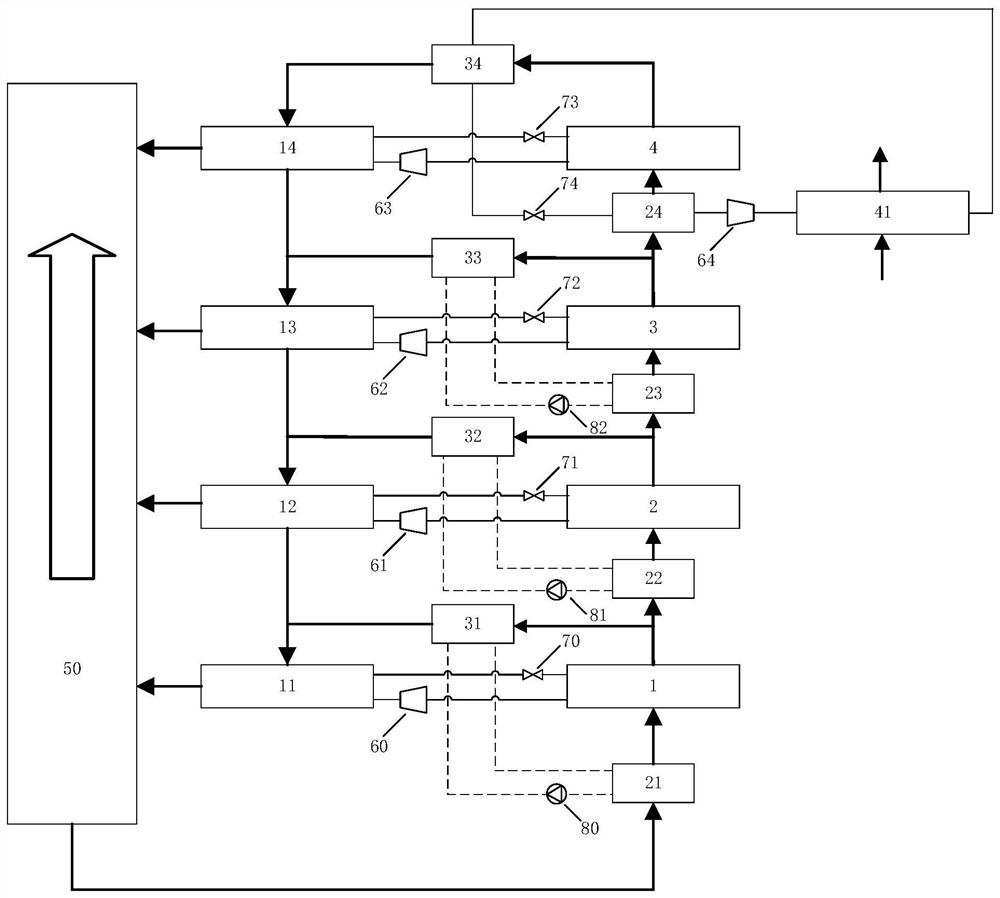

[0162] This embodiment is similar to that of Embodiment 1 in terms of basic principles and component connections, the main difference being that a refrigerant cycle is used instead of a heat pipe cycle to remove waste heat. see image 3 Specifically, the fourth pre-cooling heat exchanger 24 and the fourth pre-heating heat exchanger 34 are connected by refrigerant circulation, and connected to the outdoor heat exchanger 41 as a condenser to remove waste heat from the drying tunnel. Since the air at the end is a deep dehumidification link, the refrigerant evaporation temperature required is the lowest, so the refrigerant cycle for heat dissipation is set at the last stage of the end to improve the energy efficiency of the refrigerant cycle.

[0163] In the present embodiment, the air flow direction and the parts connection of each cycle are as follows:

[0164] Air circulation flow path:

[0165] The first air cycle: drying tunnel return air → first pre-cooling heat exchanger ...

Embodiment 3

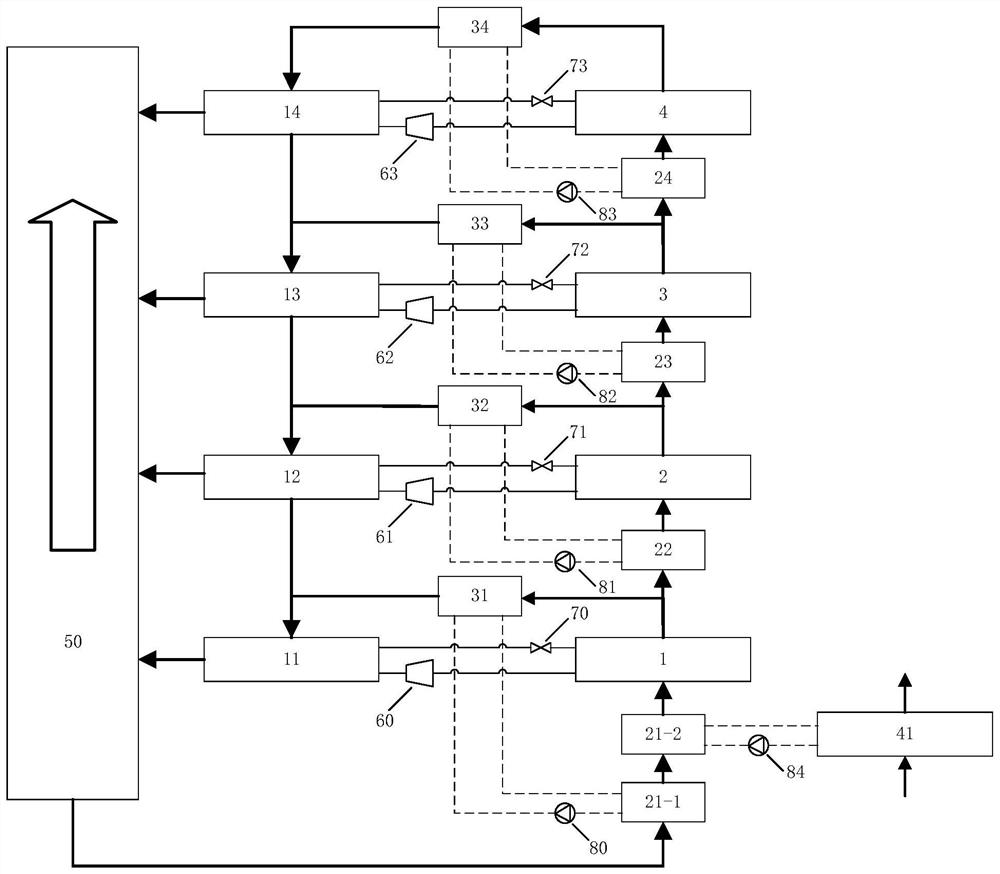

[0177] The basic principle and component connections of this embodiment are similar to those of Embodiment 1, and the main difference is that fresh air is used to heat and dehumidify to remove waste heat. see Figure 4 Specifically, the fresh air precooling heat exchanger 42 and the fresh air preheating heat exchanger 43 are used to circulate the refrigerant, the fresh air 51 is heated and sent to the drying tunnel 50 for dehumidification, and the moisture-laden exhaust air is recovered and sent to the Outdoor 52, used to eliminate waste heat in the drying tunnel.

[0178] In the present embodiment, the air flow direction and the parts connection of each cycle are as follows:

[0179] Air circulation flow path:

[0180] The first air cycle: drying tunnel return air → first pre-cooling heat exchanger 21 → first evaporator 1 → first pre-heating heat exchanger 31 → first condenser 11 (mixed with the second condenser 12 split part) →The first air supply port

[0181] The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com