Biochar modified film for dgt device, dgt device and manufacturing method thereof

A production method and biochar technology, applied in the field of environmental pollution control, can solve the problems of not considering the migration process of heavy metals, poor regional applicability, lack of DGT technology heavy metal bioavailability prediction, etc., and achieve high prediction efficiency, low cost, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Biochar-modified film diffusion gradient device (B-DGT) and its fabrication

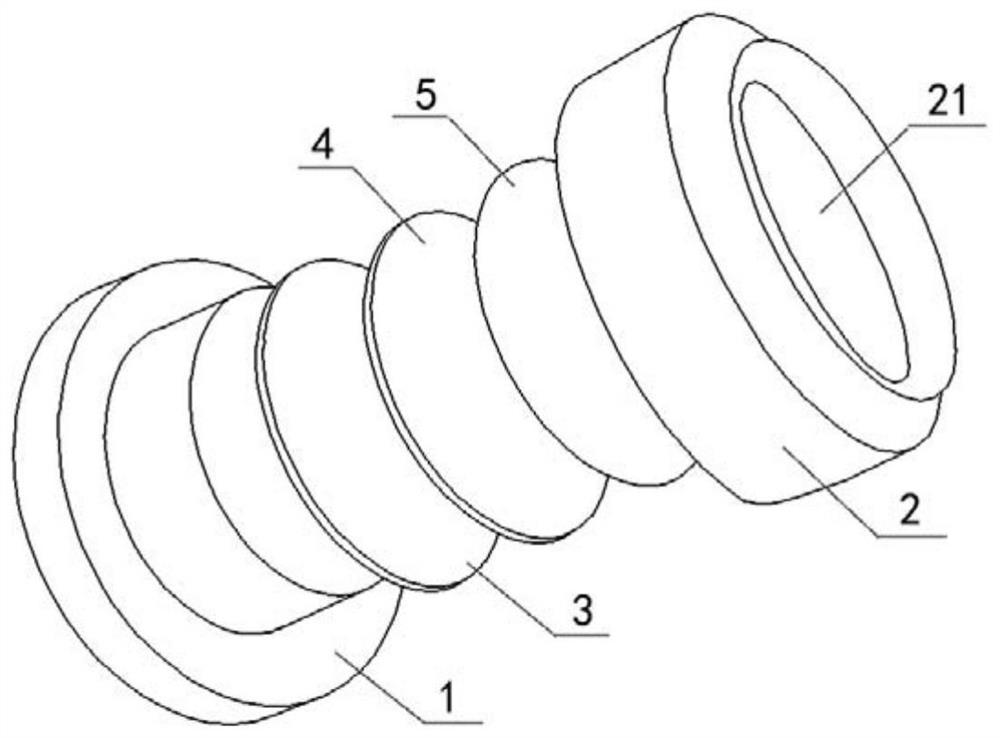

[0058] The structure of the B-DGT used in this example can be found in figure 1 , comprising a DGT core module and a shell for accommodating and fixing the DGT core module; wherein, the shell includes a base 1 and a cap 2, and the cap 2 is provided with an exposure window 21; the DGT core module includes a binding film 3, a diffusion Membrane 4 and filter membrane 5, filter membrane 5 seals exposure window 21; Wherein, binding membrane 3 is the biochar modified film that this embodiment makes, base 1 and cap 2 are ABS plastics, diffusion membrane 4 is this embodiment The material of the obtained agar diffusion membrane, the filter membrane 5 is PES.

[0059] The B-DGT used in the present embodiment is made by the laboratory, and the specific method is as follows:

[0060] 1.1 Preparation steps of agar solution and agar diffusion membrane:

[0061] Take an appropriate amount of agar pow...

Embodiment 2

[0110] This example is the same as the steps in Section 1.2 of Example 1, except that the ratio of the biochar mixture to the agar solution is different. In this example, the effects of different ratios of biochar mixture and agar solution to prepare binding membranes were compared as follows: Figure 10 As shown, among them, Figure 10 A in the figure shows the binding membrane prepared according to the volume ratio of the biochar mixture and the agar solution at 1:1. From the figure, the phenomenon of partial agglomeration of the biochar can appear, which affects the effect of the binding membrane; Figure 10 c in the figure shows the binding membrane prepared according to the volume ratio of biochar mixture and agar solution of 1:5. Although the biochar dispersibility is good, the mechanical strength is poor, which is not conducive to the extraction and maintenance of the membrane; while Figure 10 The b in the figure shows the binding membrane prepared according to the vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com