Full droplet rectifier and fluid droplet displacement control system

A fluid droplet and rectifier technology, applied in the field of chemical instruments, can solve the problems of single transmission direction, difficult to transport active substances, low transmission rate, etc., and achieve the effects of high flexibility, outstanding practical value, and good transmission effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

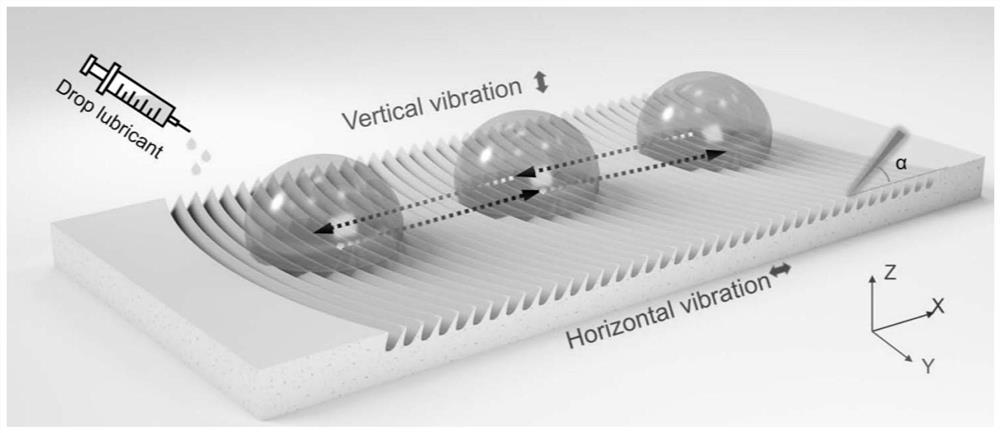

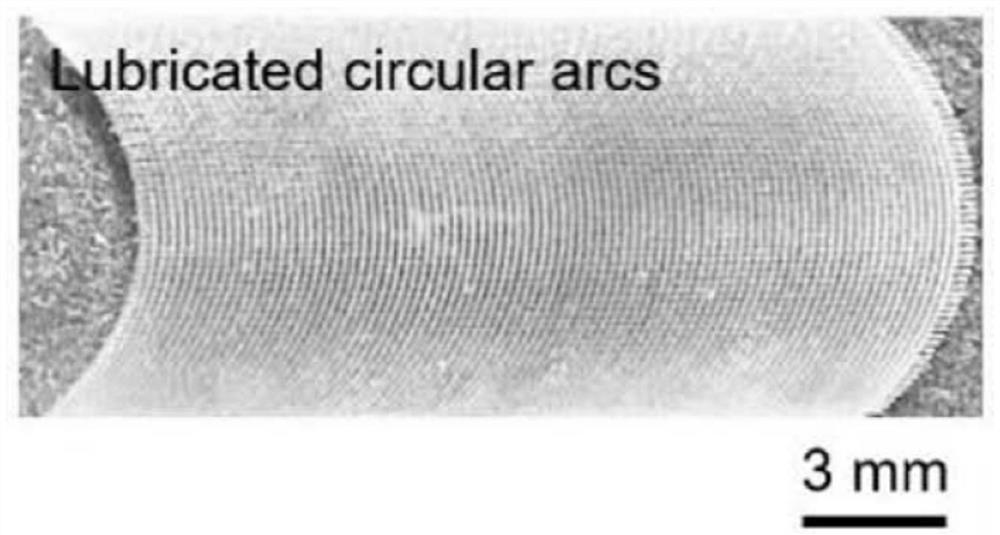

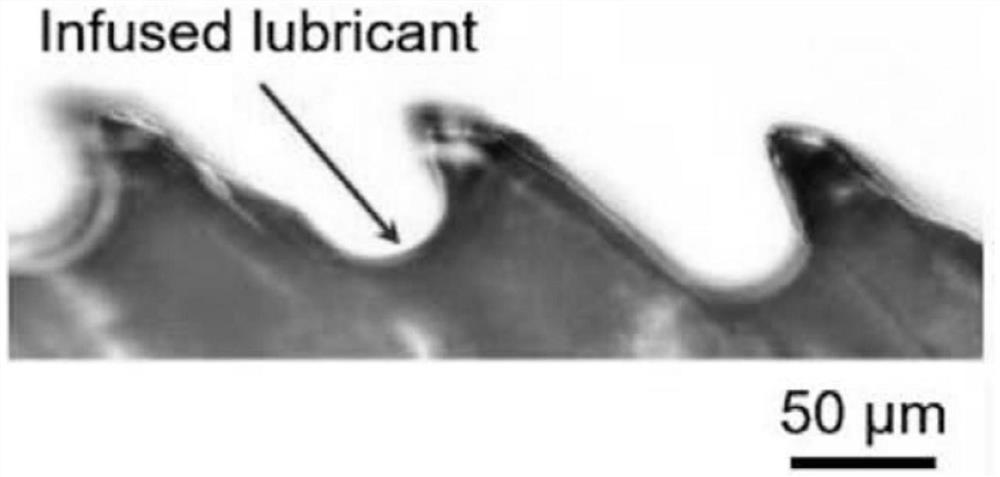

[0063] This embodiment provides a full droplet rectifier for controllably directional moving droplets of a target fluid. (In the following description, "target fluid" refers to the liquid substance to be delivered, such as sodium chloride solution, ethanol, water, glycerol, olive oil, etc. "droplet" refers to the specific form of the target fluid during delivery.) Full liquid The structure of the drop rectifier is as follows figure 1 and figure 2 As shown, it includes a substrate and a plurality of arc-shaped ratchet units on the surface of the substrate. Wherein, the base material is in the shape of a strip-shaped plate. The ratchet units are arranged on the upper surface of the base material in parallel and at equal intervals, and are sequentially arranged in a fish scale shape along the extending direction of the base material. like image 3 As shown, the side of the ratchet unit is similar to the ratchet in the ratchet, the ratchet unit is inclined toward the center s...

Embodiment 2

[0097] This embodiment provides a fluid droplet displacement control system, which is used to directionally transport any type of target fluid in the form of droplets according to a target flow rate to a target direction. Specifically, the displacement control system provided in this embodiment includes: a signal generator, a vibration generator, a full droplet rectifier, a droplet injector, and a controller.

[0098] Wherein, the signal generator is used to generate a vibration control signal including the vibration direction, amplitude and vibration frequency, and / or generate a rotation signal including the rotation angle according to the manually inputted control instructions including the moving speed and the moving direction. Wherein, the vibration direction, amplitude and vibration frequency constitute a first variable group, and the moving direction and moving speed constitute a second variable group; the signal generator is preset with a mapping relationship between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com